High-efficiency diamond bit

A diamond drill bit, high-efficiency technology, applied in the field of mechanical processing, can solve the problems of poor sharpness, affecting the production efficiency of stone processing, poor wear resistance, etc., and achieve the effect of not easy to fall off, stable welding method, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

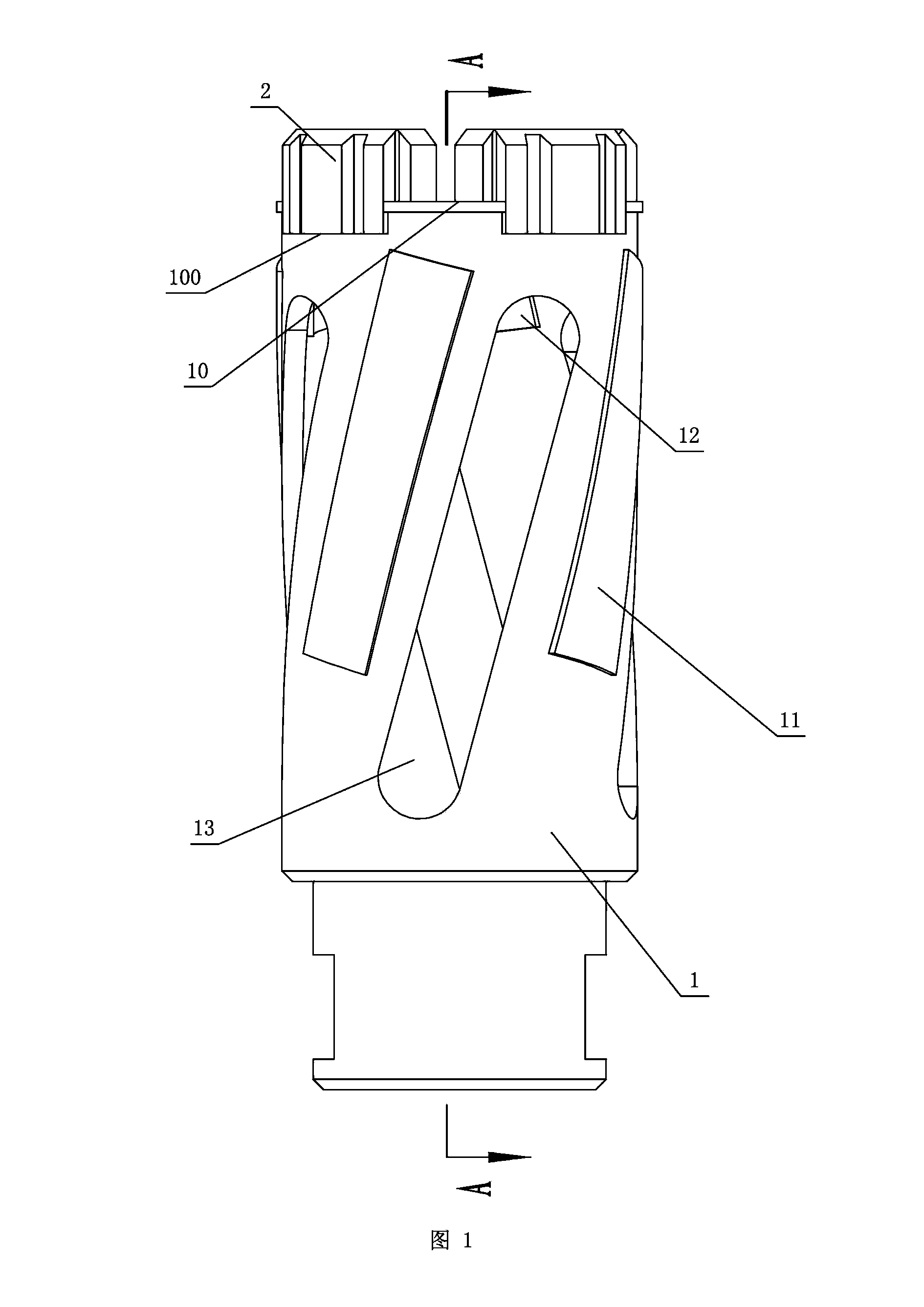

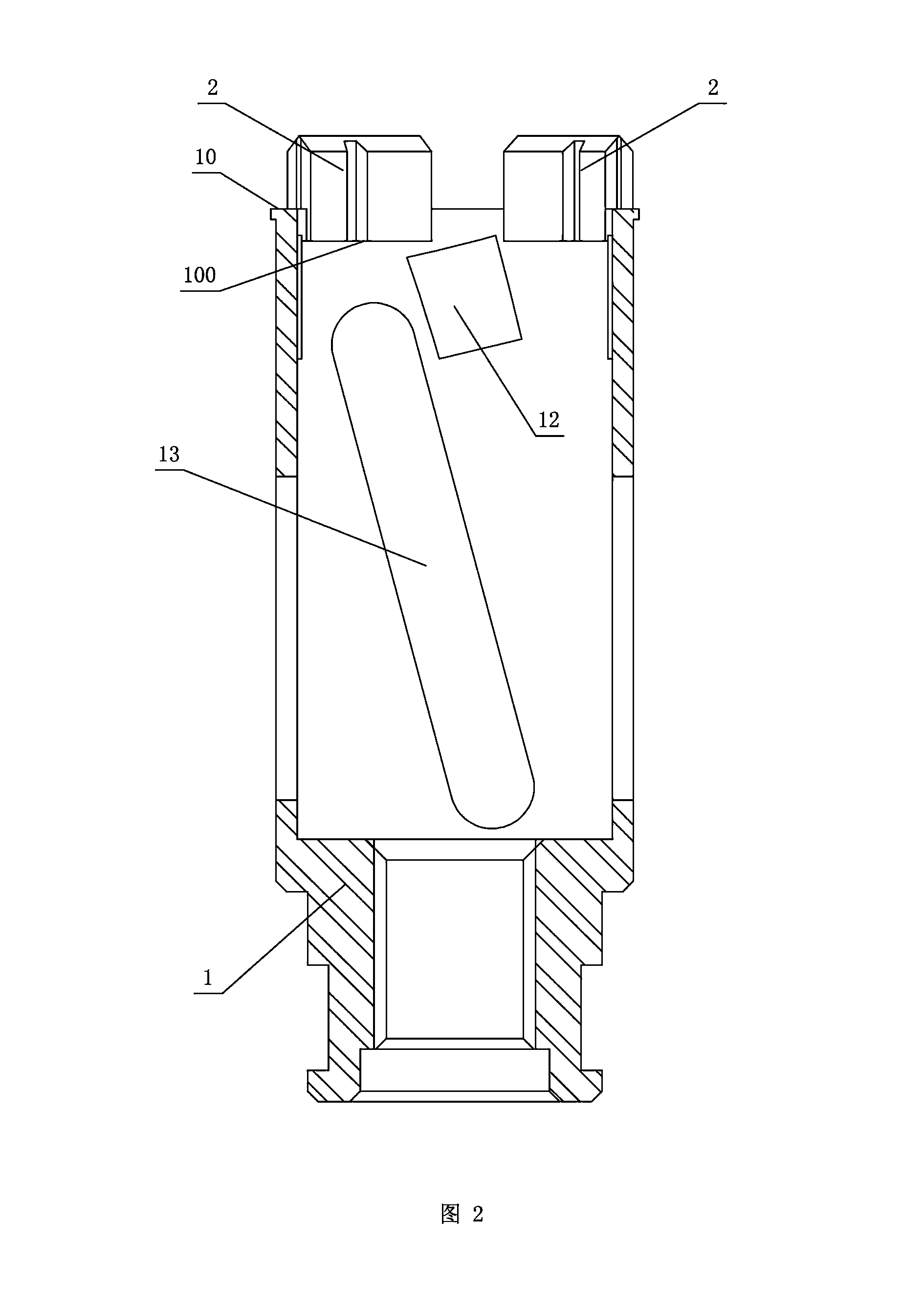

[0025] refer to figure 1 with figure 2 . A high-efficiency diamond drill bit, including a substrate and a cutter head 2, the substrate is a steel substrate 1, and its top end surface 10 is provided with a notch 100 for assembling the cutter head 2, and the connecting part of the cutter head 2 is welded in the notch 100 , the depth of the notch 100 is 3 mm.

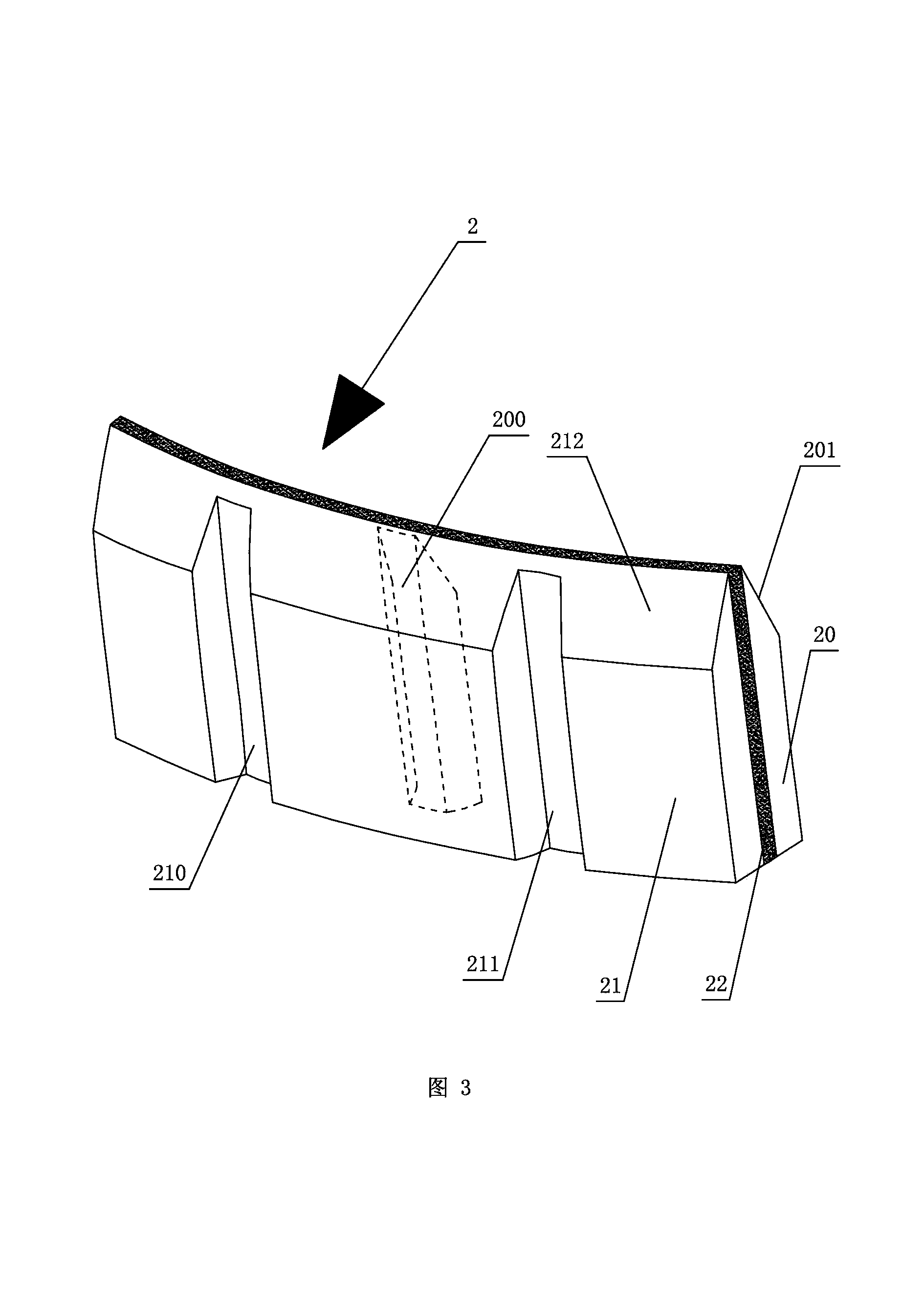

[0026] refer to figure 1 with image 3 . The cutter head 2 is composed of an inner sharp carcass 20, an outer sharp carcass 21, and a wear-resistant hard carcass 22 sandwiched between the inner and outer sharp carcass. The thickness of the wear-resistant hard carcass 22 is approximately The inner and outer sharp carcass 20, 21 and wear-resistant hard carcass 22 are sintered and formed by mixing diamond particles and pre-alloyed powder. The pre-alloyed powders of the inner and outer sharp carcass 20, 21 all include the following components by weight percentage: 41% cobalt, 22% iron, 6% nickel, 24% copper, and 7% tin;...

Embodiment 2

[0037]The implementation of this embodiment is basically the same as that of Embodiment 1, the difference is that the sharp carcass is made by atomization treatment according to the weight percentage configuration of 39% cobalt, 20% iron, 8% nickel, 25% copper, and 8% tin Pre-alloyed powder; according to the weight percentage of 36% cobalt, 17% iron, 10% nickel, 9% tungsten, 20% copper, and 8% tin, the pre-alloyed powder made of wear-resistant hard matrix is prepared through atomization treatment; The proportion by weight is diamond particles: pre-alloyed powder = 3:97.

Embodiment 3

[0039] The implementation of this example and Example 1 is basically the same, the difference is that the sharp carcass is made by atomization treatment according to the weight percentage configuration of 40% cobalt, 18% iron, 10% nickel, 26% copper, and 6% tin Pre-alloyed powder; according to the weight percentage of 40% cobalt, 14% iron, 8% nickel, 6% tungsten, 23% copper, and 9% tin, the pre-alloyed powder made of wear-resistant hard matrix is prepared through atomization treatment; The proportion by weight is diamond particles: pre-alloyed powder = 5:95.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com