Novel two-dimensional nano paint

A two-dimensional nano-coating technology, applied in the field of coatings, can solve the problems that affect the appearance of exterior walls and the quality of exterior walls, the low UV absorption function of coatings, and the inability to achieve thermal insulation effects, so as to achieve good shielding of ultraviolet rays and microwave absorption. , Improve appearance, strengthen the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

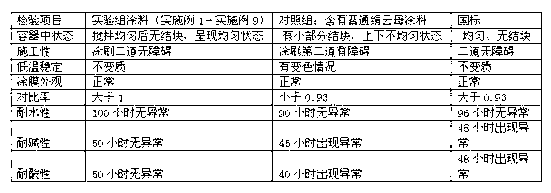

Examples

Embodiment 1

[0022] A new type of two-dimensional nano-coating, said coating includes the following components, according to the mass ratio as follows: 20 parts of epoxy resin, 10 parts of kaolin, 1 part of antibacterial agent, 1 part of anti-fungal agent, 30 parts of two-dimensional nano-sericite 10 parts of water, 10 parts of titanium dioxide, 10 parts of alumina powder, 1 part of dispersant, 2 parts of expanded perlite, 1 part of film-forming aid, 5 parts of quartz powder, 15 parts of melamine, 20 parts of aluminum silicate, 8 parts of silicon oxide, 1 part of barium sulfate, 1 part of defoamer, 1 part of wetting agent, 30 parts of mixed solvent, 10 parts of zinc oxide, 20 parts of zinc phosphate, 5 parts of sodium hydroxide, 1 part of hydrochloric acid, wherein the mixed solvent is Xylene, methanol, wherein the mass ratio of xylene and methanol is 2:1. The coating has good chemical stability, excellent heat resistance, acid and alkali resistance, and antibacterial and mildew-proof effe...

Embodiment 2

[0024] A new type of two-dimensional nano-coating, the coating includes the following components, according to the mass ratio as follows: 20-25 parts of epoxy resin, 10-18 parts of kaolin, 1-3 parts of antibacterial agent, 1-5 parts of antifungal agent 30-45 parts of two-dimensional nano-sericite, 10-20 parts of water, 10-14 parts of titanium dioxide, 10-13 parts of alumina powder, 1-2 parts of dispersant, 2-4 parts of expanded perlite, film-forming 1-2 parts of additives, 5-10 parts of quartz powder, 15-25 parts of melamine, 20-30 parts of aluminum silicate, 8-15 parts of silicon oxide, 1-3 parts of barium sulfate, 1-3 parts of defoamer, 1-3 parts of wetting agent, 30-35 parts of mixed solvent, 10-18 parts of zinc oxide, 20-38 parts of zinc phosphate, 5-10 parts of sodium hydroxide, 1-8 parts of hydrochloric acid, and the mixed solvent is xylene, methanol , wherein the mass ratio of xylene and methanol is 3:2.

Embodiment 3

[0026] A new type of two-dimensional nano-coating, said coating includes the following components, according to the mass ratio as follows: 21 parts of epoxy resin, 11 parts of kaolin, 1.1 parts of antibacterial agent, 1.1 parts of anti-fungal agent, 33 parts of two-dimensional nano-sericite 11 parts of water, 11 parts of titanium dioxide, 11 parts of alumina powder, 1.1 parts of dispersant, 2.1 parts of expanded perlite, 1.1 parts of film-forming aid, 6 parts of quartz powder, 17 parts of melamine, 22 parts of aluminum silicate, 10 parts of silicon oxide, 1.1 parts of barium sulfate, 1.3 parts of defoamer, 1.3 parts of wetting agent, 31 parts of mixed solvent, 11 parts of zinc oxide, 21 parts of zinc phosphate, 6 parts of sodium hydroxide, 2 parts of hydrochloric acid. The mixed solvent is dimethyl phthalate and ethanol, and the mass ratio of dimethyl phthalate and ethanol is 2.5:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com