Method for manufacturing dental cobalt-chromium ceramic alloy disc material

A production method and cobalt-chromium technology, which are applied in dentistry, medical science, filling teeth, etc., can solve problems such as affecting the health of workers, a large amount of garbage, smoke and dust, and low denture processing efficiency, and achieve good compactness and good biological properties. Compatibility, simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

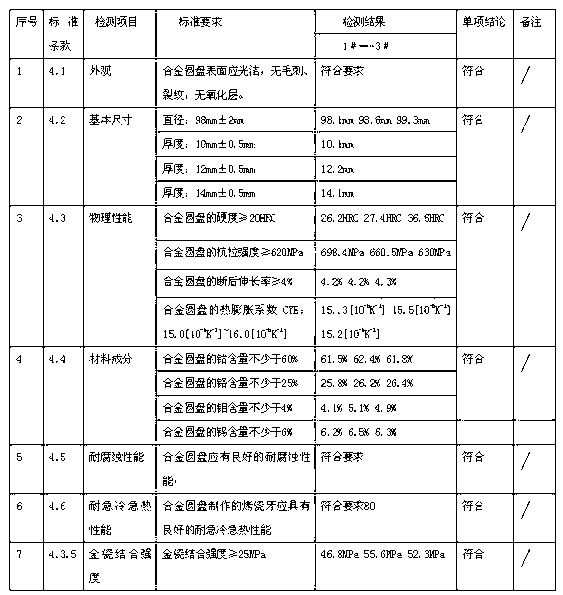

Embodiment 1

[0019] Embodiment one: A, preparation charge: prepare cobalt (Co) 61%, chromium (Cr) 26%, molybdenum (Mo) 4.5%, tungsten (W) 6.5%, titanium (Ti) 0.5%, silicon ( Si) 0.5%, iron (Fe) 0.3%, manganese (Mn) 0.7%; B. Put the charge into the furnace for vacuum smelting and vacuum casting, and then roll it with a rolling mill. The rolling temperature is 1200°C, and the rolling deformation It is 2.6%, and the rolling pass is 6 passes to form a semi-finished material; C. After the semi-finished material is processed by wire cutting and lathe turning according to the required thickness, dental materials of different thicknesses suitable for CAD / CAM tooth carving machines are obtained. A new material for cobalt-chromium ceramic alloy discs.

Embodiment 2

[0020] Embodiment two: A, preparation charge: prepare cobalt (Co) 62%, chromium (Cr) 25.5%, molybdenum (Mo) 4.5%, tungsten (W) 7%, titanium (Ti) 0.2%, silicon ( Si) 0.1%, iron (Fe) 0.2%, manganese (Mn) 0.5%; B. Put the furnace charge into the furnace for vacuum smelting and vacuum casting, and then roll it with a rolling mill. The rolling temperature is 1250°C, and the rolling deformation It is 3.7%, and the rolling pass is 4 passes to form a semi-finished material; C. After the semi-finished material is processed by wire cutting and lathe turning according to the required thickness, dental materials of different thicknesses suitable for CAD / CAM tooth carving machines are obtained. A new material for cobalt-chromium ceramic alloy discs.

Embodiment 3

[0021] Embodiment three: A, prepare charge: prepare cobalt (Co) 60.5%, chromium (Cr) 25.5%, molybdenum (Mo) 5%, tungsten (W) 7%, titanium (Ti) 0.7%, silicon ( Si) 0.3%, iron (Fe) 0.4%, manganese (Mn) 0.6%; B. Put the furnace charge into the furnace for vacuum smelting and vacuum casting, and then roll it with a rolling mill. The rolling temperature is 1300°C, and the rolling deformation It is 4.8%, and the rolling pass is 2 passes to form a semi-finished material; C. After the semi-finished material is processed by wire cutting and lathe turning according to the required thickness, dental materials of different thicknesses suitable for CAD / CAM tooth carving machines are obtained. A new material for cobalt-chromium ceramic alloy discs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com