High-temperature-resisting pressure-sensitive adhesive for adhesive tape, adhesive tape and preparation process

A pressure-sensitive adhesive and high-temperature-resistant technology, which is applied in the direction of adhesives, natural rubber adhesives, non-polymer adhesive additives, etc., can solve the problems of poor peeling performance, high temperature resistance, high production cost, and low grafting efficiency , to achieve the effects of improved temperature resistance and aging resistance, reduced preparation cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

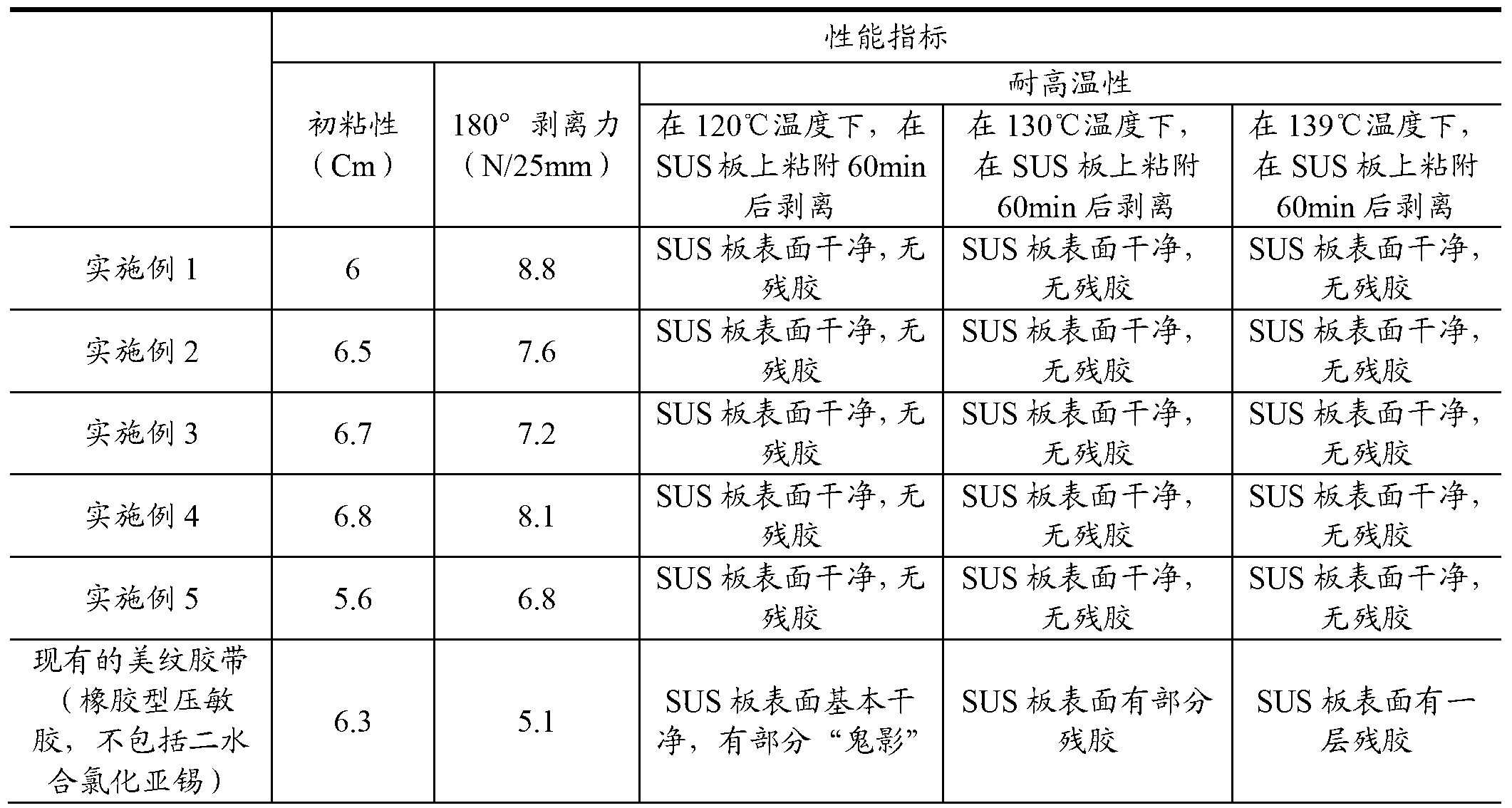

Examples

preparation example Construction

[0047] The embodiment of the present invention also discloses a method for preparing the above-mentioned high-temperature-resistant pressure-sensitive adhesive for adhesive tape, the operation steps of which are as follows:

[0048] a) Mix the main rubber and auxiliary material additives, and knead them in an open mill or internal mixer to obtain a kneaded product; preferably, the auxiliary material additives can be mixed with the main rubber in different periods of time to improve the effect of the auxiliary material additives on the main rubber Effect;

[0049] b), mixing the kneaded product obtained in the above step a) with a solvent, and dissolving the kneaded product in the solvent;

[0050] c), during the process of dissolving the kneaded product in the above step b), add a tackifier and a plasticizer to the kneaded product, stir until completely dissolved, and obtain a pressure-sensitive adhesive;

[0051] d), adding a curing agent to the pressure-sensitive adhesive o...

Embodiment 1

[0064] A high-temperature-resistant pressure-sensitive adhesive for adhesive tapes, including main rubber, auxiliary material additives, tackifiers, plasticizers, solvents and curing agents;

[0065] The preparation method of the high temperature-resistant pressure-sensitive adhesive for the adhesive tape of the present embodiment 1, its operation steps are:

[0066] a) The main rubber composed of 1kg natural rubber smoked sheet rubber, 0.33kg styrene-butadiene rubber and the auxiliary materials composed of 6.6g zinc oxide, 53g titanium dioxide, 13.3g stannous chloride dihydrate, 10.6g anti-aging agent (2462) The additives are mixed, and the triangular bag is made 6-9 times on an open mill or an internal mixer to obtain a mixture, and the mixture is cut into small pieces;

[0067] b) Take 100g of the above kneaded mixture, mix it with 233g of toluene (solvent), and dissolve the mixture in toluene;

[0068] c), in the process of dissolving the kneaded product in the above step...

Embodiment 2

[0077] A high-temperature-resistant pressure-sensitive adhesive for adhesive tapes, including main rubber, auxiliary material additives, tackifiers, plasticizers, solvents and curing agents;

[0078] The preparation method of the high temperature resistant pressure-sensitive adhesive for the adhesive tape of the present embodiment 2, its operation steps are:

[0079] a) The main rubber composed of 1kg natural rubber smoked sheet rubber, 0.33kg styrene-butadiene rubber and 6.6g zinc oxide, 53g alumina powder, 13.3g stannous chloride dihydrate, 10.6g anti-aging agent (2462) The auxiliary materials and additives are mixed, and the triangular bag is made 6-9 times on an open mill or an internal mixer to obtain a mixture, and the mixture is cut into small pieces;

[0080] b) Take 100g of the above kneaded mixture, mix it with 233g of toluene (solvent), and dissolve the mixture in toluene;

[0081] c), during the process of dissolving the kneaded product in the above step b), add a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com