Method for processing lignocellulosic biomass at constant pressure with ammonia and diluted alkali combined

A lignocellulosic and lignocellulose technology, which is applied in the pretreatment and application fields of biomass energy, can solve the problems of difficult sorting and removal of lignin, high loss rate of hemicellulose, high energy consumption of ammonia recovery, etc., to achieve The pretreatment process is simple, the environmental pollution is small, and the effect of reducing the addition of nitrogen sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

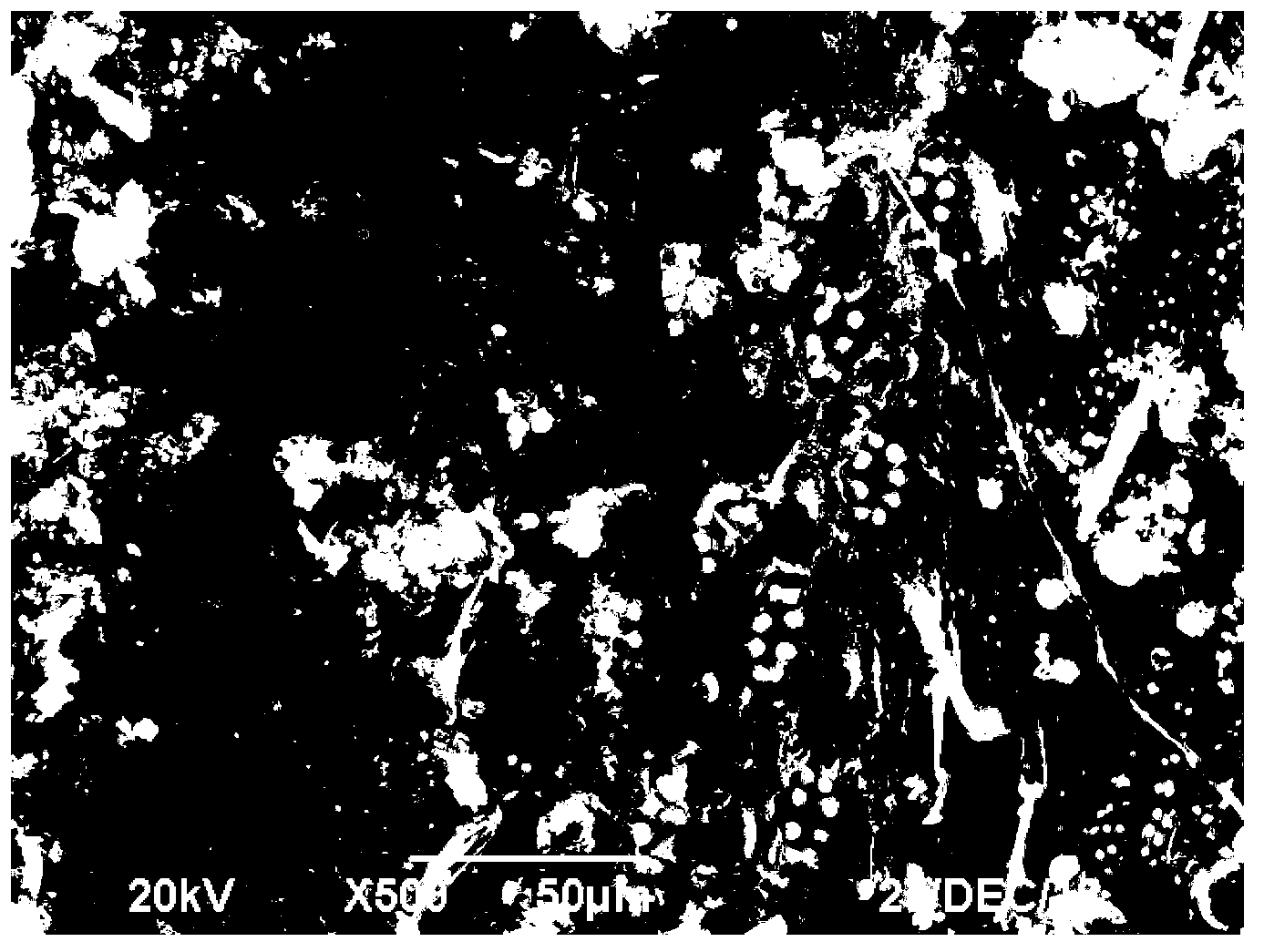

reference example 1

[0026] Reference example 1: Chop the rice straw to -2cm, take 10.0g, wash with 2% dilute NaOH solution at 95°C for 2 hours to obtain 5.2g (dry weight) of lignocellulose, which contains 3.3g of cellulose and 1.2 hemicellulose g, the lignin stripping rate is 82.5%; the cellulase produced by the solid-state fermentation of Trichoderma viride (Trichoderma viride) ZY-1 is used for saccharification and degradation to produce reducing sugar, and the substrate is 50 FPIU / g, and the solid-liquid ratio is 1:10 , saccharified and degraded at 50°C for 48 hours, the reaction was terminated, and the saccharified solution was extracted to obtain 4.2 g of reducing sugar, and the yield of reducing sugar was 80.2%.

reference example 2

[0027] Reference example 2: Chop the rice straw to -2cm, take 10.0g, and pass NH at 50°C 3After 2 hours of treatment, wash with 2% dilute NaOH solution at 95°C for 2 hours to obtain 5.1g (dry weight) of lignocellulose, which contains 3.2g of cellulose and 1.1g of hemicellulose, and the lignin stripping rate is 81.8%. ;The cellulase produced by Trichoderma viride (Trichoderma viride) ZY-1 solid-state fermentation was used for saccharification and degradation to produce reducing sugar. The substrate was selected to be 50FPIU / g, the solid-liquid ratio was 1:10, and the saccharification and degradation was carried out at 50°C for 48 hours. The reaction was terminated, and the saccharification solution was extracted to obtain 4.1 g of reducing sugar, and the yield of reducing sugar was 80.3%.

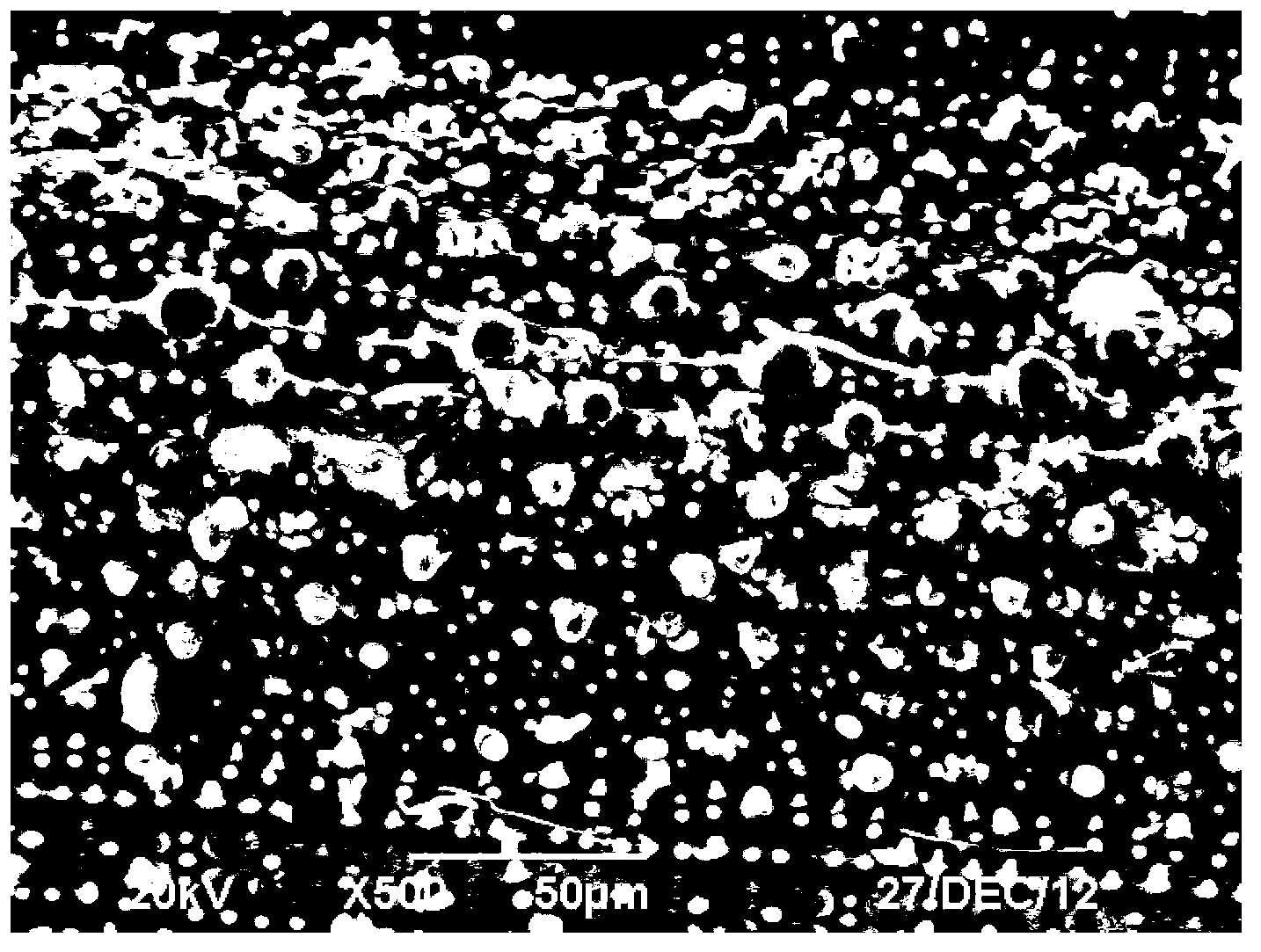

Embodiment 1

[0028] Implementation Example 1 : Chopped rice straw to -2cm, took 10.0g, fumigated with ammonia water at 50°C for 2h, then washed with 2% dilute NaOH solution at 95°C for 2h to obtain 5.6g (dry weight) of lignocellulose, It contains 3.9 g of cellulose, 1.4 g of hemicellulose, and the stripping rate of lignin is 91.2%; the cellulase produced by solid-state fermentation of Trichoderma viride (Trichoderma viride) ZY-1 is used for saccharification and degradation to produce reducing sugar, and 50 FPIU / g is selected The substrate was saccharified and degraded at 50°C for 48 hours at a solid-to-liquid ratio of 1:10. The reaction was terminated, and the saccharified liquid was extracted to obtain 5.1 g of reducing sugar, with a yield of 90.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com