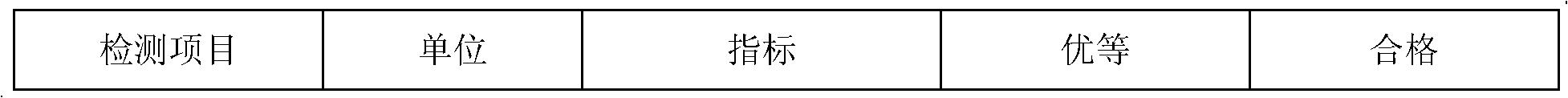

Solid wood composite floor and preparation method thereof

A solid wood composite flooring and flooring technology, which is applied in the direction of wood layered products, wooden veneer joints, chemical instruments and methods, etc., and can solve the problems of short practical life, low density, and easy cracking of floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] First, prepare the floor surface

[0087] 1. Veneer dyeing treatment

[0088] 1-1) Spin the fast-growing poplar into poplar veneer with a thickness of 0.8mm, and select the spin-cut poplar veneer without holes, skin and burr, and the moisture content of the veneer is 25-35% in the natural state ,spare;

[0089]1-2) Add wood stains, dyeing auxiliaries (yuanming powder, penetrant, defoamer, etc.) and water to the dyeing machine in proportion, and turn on the circulating pump to make the dye liquor evenly; then heat up and keep The temperature is 90-95°C; then immerse the eucalyptus veneer in the dye solution of the dyeing machine, dye the veneer, check the color to meet the requirements, take out the veneer, clean and filter the dye solution on the surface; among them, according to the veneer The different colors of the veneer are selected, the concentration of the dye solution is 0.3-0.5%, and the dyeing time is 3-8h, which is determined according to the thickness of t...

Embodiment 2

[0136] The procedure is the same as in Example 1, except that the surface of the prepared parquet is subjected to conventional paint coating treatment.

[0137] The concrete method of paint processing of the present invention is as follows:

[0138] 1) Roller primer

[0139] A) Roll coating UV water-based primer (Shanghai Xiechengchang Chemical Co., Ltd.) on the surface of paint-free solid wood composite floor, then adopt infrared drying, sanding, wherein the consumption of water-based primer is 10-20g / cm 2 ;

[0140] B) On the surface of the composite floor coated with the water-based anti-UV primer, the UV sanding primer (Shanghai Xiechengchang Chemical Co., Ltd., B-4235G) was rolled 3 times, and the amount of the UV primer for each roll was 15-30g / cm 2 , use infrared drying after each roll coating, and then carry out anti-UV primer roll coating after sanding;

[0141] 2) Roller coating with wear-resistant paint

[0142] Roll-coat wear-resistant paint (Shanghai Xiecheng...

Embodiment 3

[0148] First, prepare the floor surface

[0149] In the veneer dyeing process, except that the veneer thickness is 1.5mm and the moisture content is 20%, the rest is the same as that of Example 1;

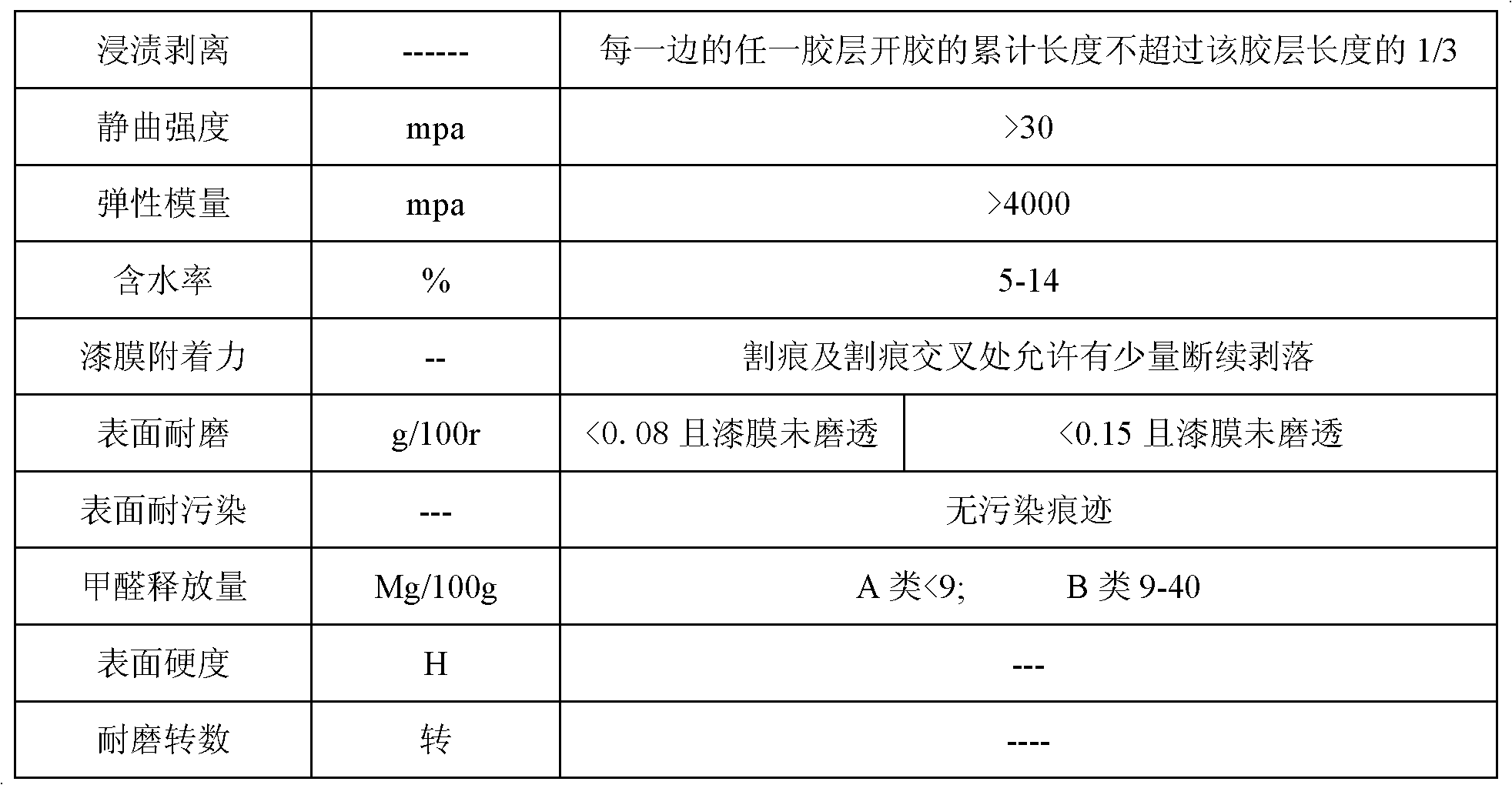

[0150] In the process of preparing wood softener, the weights of SMQ-05, penetrant JFC, peregal O and water were 25kg, 2kg, 6kg, and 100kg respectively; the weight of the first batch of water accounted for 30% of the total weight of water, and the first heating The temperature of heating up is 50 ℃, and the temperature of the second heating and heating is 70 ℃, and the rest are the same as in Example 1;

[0151] In the process of preparing the dipping solution, except the raw material weights are as follows: the weights of urea, formaldehyde, melamine, polyvinyl alcohol, softener and triethanolamine are respectively 200kg, 610kg, 190kg, 50kg, 30kg, 20kg; the pH of the reaction first stage is 7.5, the reaction temperature is 90 ℃, the reaction time is 25min, and the amount of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com