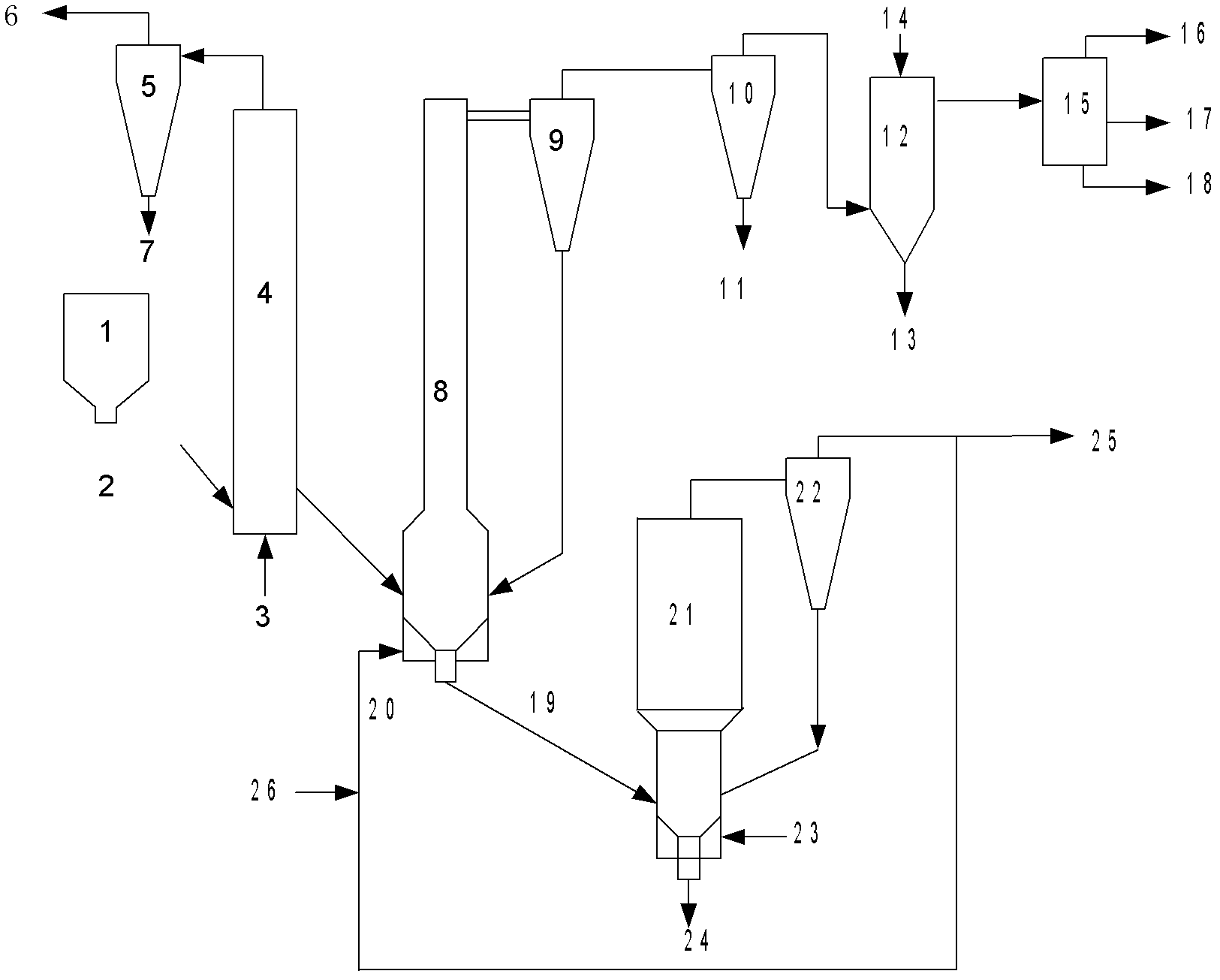

Fluidized bed low-temperature destructive distillation system and low-temperature destructive distillation method of low-rank coal

A low-rank coal and low-temperature technology, which is applied in the direction of special carbonization, direct heating carbonization, and combustible gas purification, can solve the problems of difficult ash removal of large particles, complex equipment structure, and low volume utilization of bubbling bed reactors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

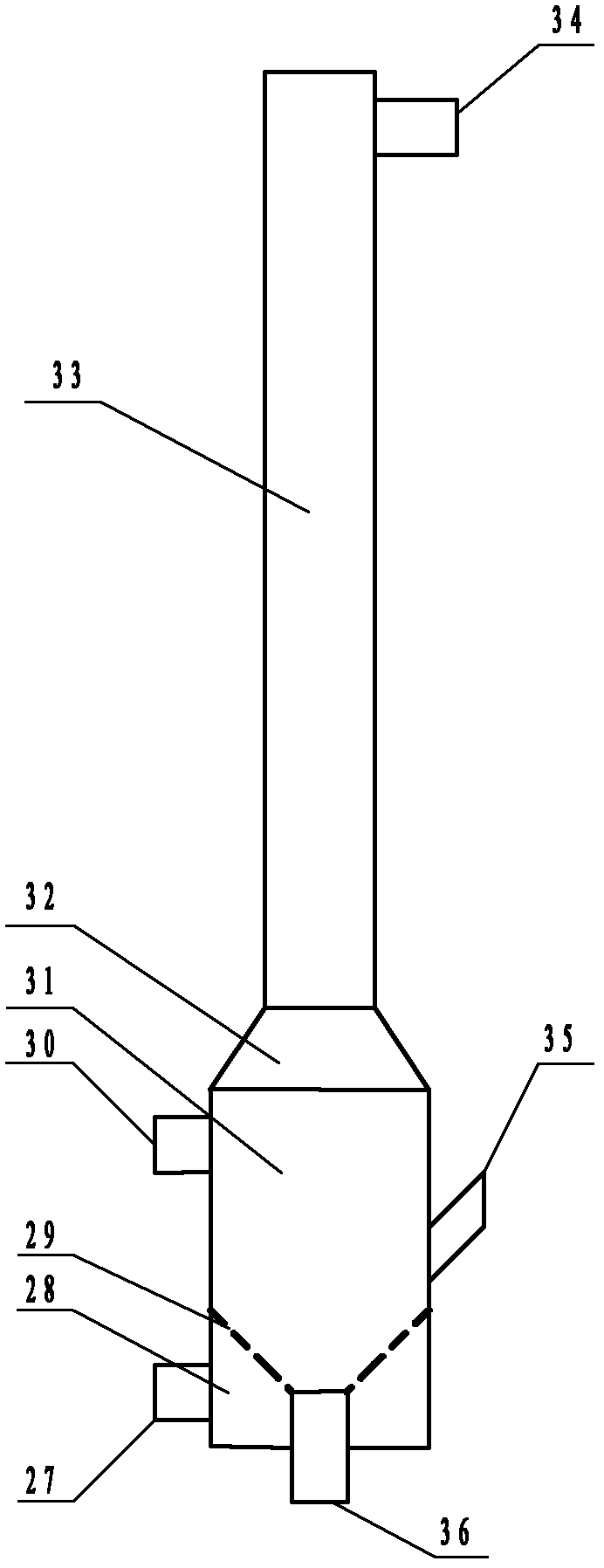

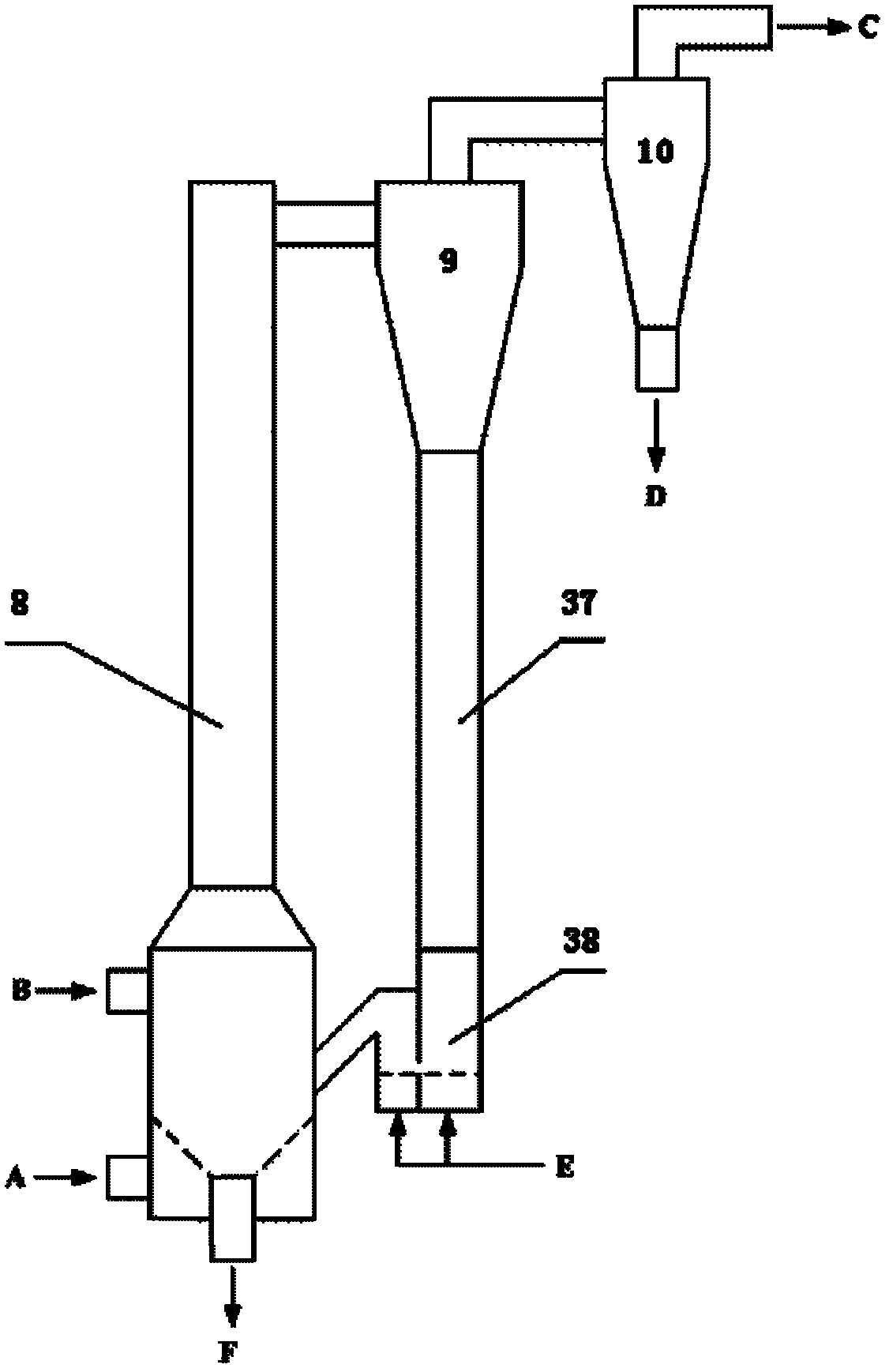

[0059] Adopt the fluidized bed low-temperature dry distillation system shown in the figure of the present invention, the diameter of the fluidized bed drying preheater is 200mm, and the height is 3000mm; the inner diameter of the upper straight pipe section of the low-temperature dry distillation reactor is 50mm, the inner diameter of the lower expanded section is 80mm, and the total height is 12000mm; The bed gasifier has a diameter of 200mm and a height of 4000mm. The raw coal is Yilan Grade 6 coal, and the coal quality analysis data are shown in Table 1.

[0060] First, the raw coal is crushed and screened, and the pulverized coal with a particle size of less than 8mm is sent to the drying preheater 4 through the coal hopper 1 and the feeder 2, and the temperature is controlled at 180-210°C for drying and preheating;

[0061] Put the preheated coal powder into the carbonization reactor 8, mix the hot gas 20 from the gasifier with the circulating cold gas 26, adjust the temp...

Embodiment 2

[0071] The fluidized bed low-temperature dry distillation device and operation steps are the same as those in Example 1. The raw coal is Yilan Grade 6 coal, and the coal quality analysis data are shown in Table 3. The raw coal particle size is controlled to be less than 8mm, the coal drying preheating temperature is 200-230°C, the low-temperature carbonization temperature is 520-550°C, the gasification temperature is 1000-1050°C, and other operating conditions are the same as in Example 1. The dry distillation hot gas is composed of: H 2 content 13-16%, CO content 11-14%, N 2 Content 45~48%, CH 4 Content 1~2%, CO 2 Content 8 ~ 12%, H 2 The O content is 14-16%. The yield of low-temperature dry distillation tar is 12.3%, the yield of semi-coke is 66.0%, and the specific gravity of low-temperature tar is 1.21g / ml. The semi-coke properties and the distillation range analysis of tar are shown in Table 3 and Table 4.

[0072] Table 3 Work points and element points data of the...

Embodiment 3

[0077] The fluidized bed low-temperature dry distillation device and operation steps are the same as those in Example 1. The raw coal is Yilan 32 rank coal, and the coal quality analysis data are shown in Table 5. The raw coal particle size is controlled to be less than 8mm, the coal drying preheating temperature is 200-230°C, the low-temperature carbonization temperature is 500-520°C, the gasification temperature is 1000-1050°C, and other operating conditions are the same as in Example 1. The dry distillation hot gas is composed of: H 2 content 10-14%, CO content 10-12%, N 2 Content 48~50%, CH 4 Content 0~1%, CO 2 Content 10-12%, H 2 O content 12-15%. The yield of low-temperature dry distillation tar is 7.3%, the yield of semi-coke is 67.8%, and the specific gravity of low-temperature tar is 1.15g / ml. The semi-coke properties and the distillation range analysis of tar are shown in Table 5 and Table 6.

[0078] Table 5 Work points and element points data of the Yilan si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com