Preparation method of storage-stable compound modified asphalt

A composite modified asphalt, stabilization technology, applied in building components, building insulation materials, construction, etc., can solve the problem that the rubber powder cannot be stabilized and uniformly dispersed, the segregation degree of the rubber powder cannot be improved well, and it is unfavorable for waste The utilization of tire rubber powder and other issues can achieve the effects of recycling and environmental protection, improving thermal storage stability, and solving the problem of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

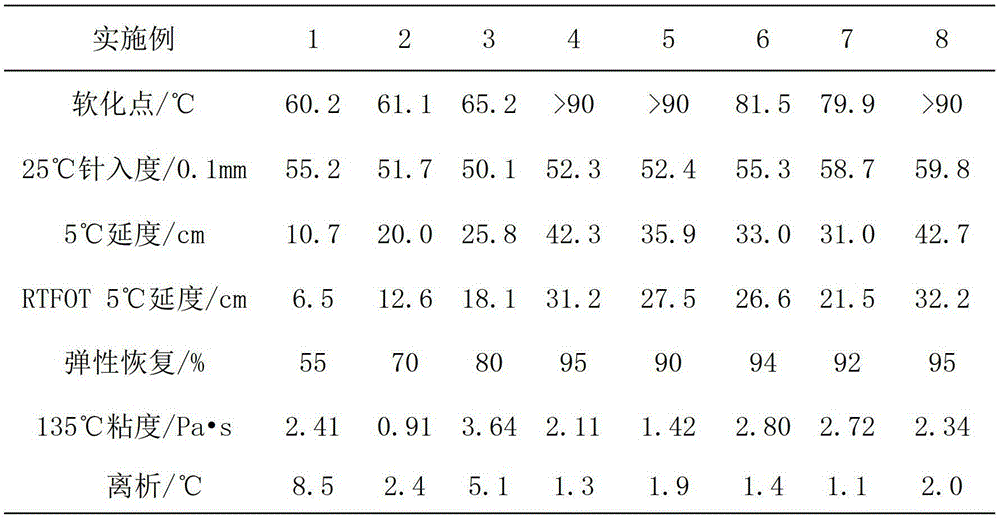

[0032] Example 4: Grinding styrene-butadiene-styrene thermoplastic elastomer (SBS) and waste tire rubber powder into powder through a pulverizer to obtain SBS powder and rubber powder; Put 50 parts by weight of rubber powder and 50 parts by weight of SBS powder into the blending reactor of the extruder, and the reaction product is water-cooled, pelletized and dried to obtain a solid SBS / rubber powder blend. By weight percentage, weigh 82.5% base asphalt, add 12% SBS / rubber powder blend, 5% compatibilizer, 0.5% stabilizer, stir and mix for 4 hours at 175-185°C to obtain a composite modified Asphalt 4#, the performance indicators are shown in Table 1.

Embodiment 5

[0033] Example 5: Grinding styrene-butadiene-styrene thermoplastic elastomer (SBS) and waste tire rubber powder into powder through a pulverizer to obtain SBS powder and rubber powder; 95 parts by weight of rubber powder and 5 parts by weight of SBS powder were put into the blending reactor of the extruder, and the reaction product was cooled by roller calendering and formed into sheets to obtain a solid SBS / rubber powder blend. According to weight percentage, weigh 90.5% base asphalt, add 3% SBS, at 130 ℃, use high-speed shear disperser to cut, add 1% SBS / rubber powder blend, 5% compatibilizer, 0.5% Stabilizer, stirred and mixed at 175°C for 4 hours to prepare composite modified asphalt 5#, the performance indicators are shown in Table 1.

Embodiment 6

[0034] Example 6: Grinding styrene-butadiene-styrene thermoplastic elastomer (SBS) and waste tire rubber powder into powder through a pulverizer to obtain SBS powder and rubber powder; 90 parts by weight of rubber powder and 10 parts by weight of SBS powder were put into the blending reactor of the extruder, and the reaction product was water-cooled, pelletized and dried to obtain a solid SBS / rubber powder blend. By weight percentage, weigh 72.5% base asphalt, add 2% SBS, and cut it with a high-speed shear disperser at 140°C, add 20% SBS / rubber powder blend, 5% compatibilizer, 0.5% Stabilizer, stirred and mixed at 180°C for 4 hours to prepare composite modified asphalt 6#, the performance indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com