A kind of preparation method of high-speed steel roll

A high-speed steel and roll technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of difficult forging, difficult production, uneven structure, etc., achieve excellent wear resistance and anti-seizure resistance, and promote refinement. and uniform distribution, improving red hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

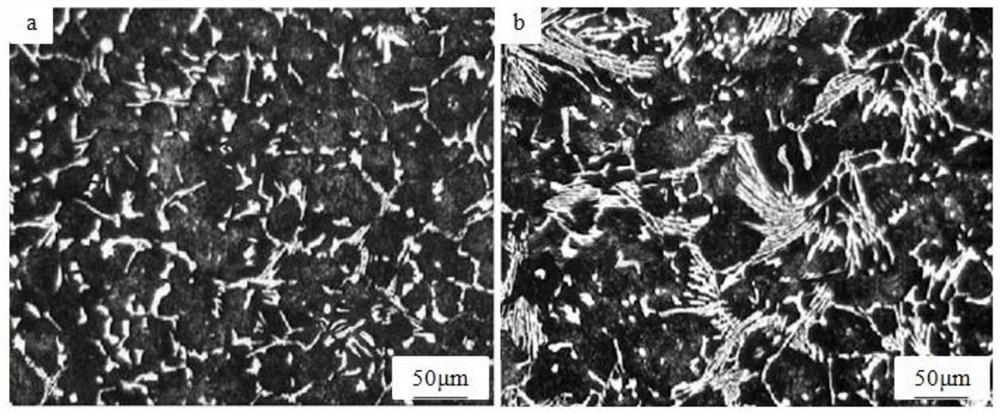

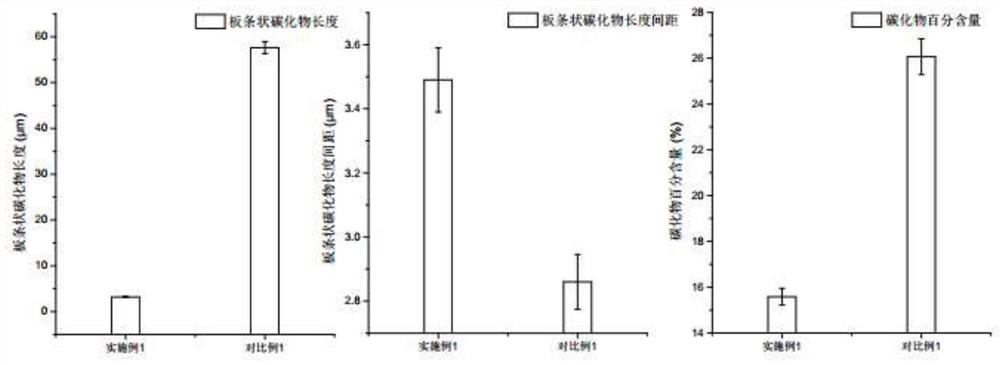

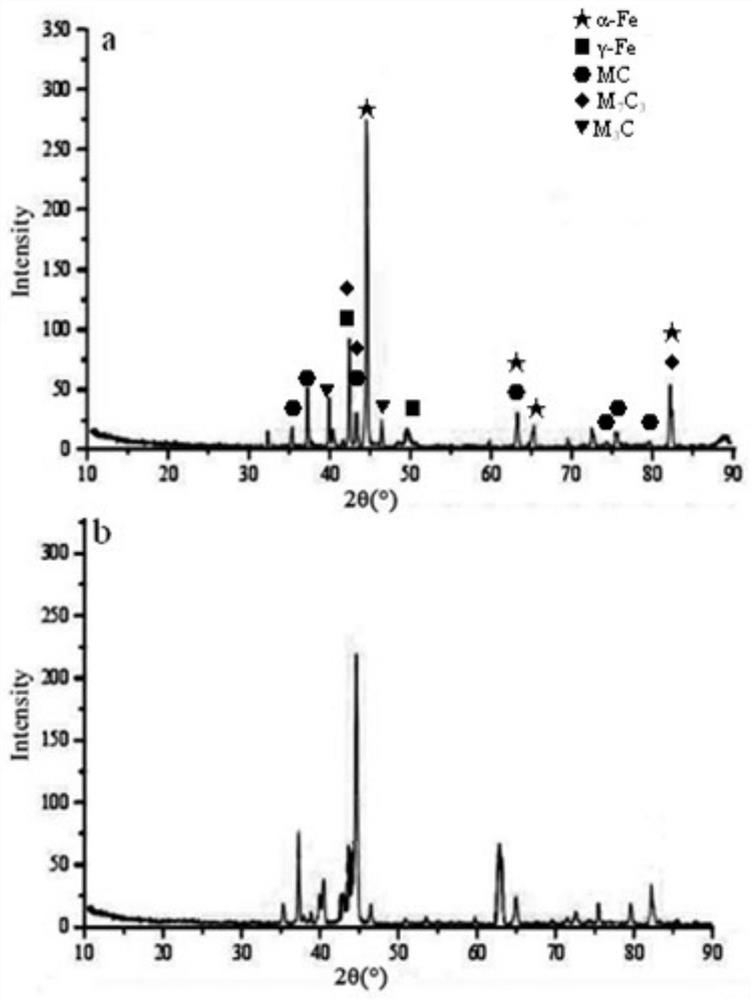

[0030] One embodiment of the present invention provides a method for preparing a high-speed steel roll. The high-speed steel roll includes an outer layer, an intermediate layer, and a core; the intermediate layer is formed on the inner surface of the outer layer, and the inner layer is formed on the inner surface of the intermediate layer; the preparation method specifically includes the following: Process:

[0031] -Smelting process, respectively smelting the high-speed molten steel in the outer layer of the roll body, the semi-steel molten steel in the middle layer, and the molten iron in the core, for use;

[0032] -casting process, using the high-speed molten steel in the outer layer of the roll body, the semi-steel molten steel in the middle layer, and the molten iron in the core to sequentially pour the outer layer, the middle layer, and the core of the roll; and,

[0033] -Heat treatment process, after 24-48h of pouring of the high-speed steel roll cast slab, take it out ...

Embodiment approach 1

[0044] In one embodiment of this embodiment, a method for preparing a high-speed steel roll specifically includes the following steps:

[0045] S1: Melting process, three intermediate frequency furnaces are used to melt the high-speed molten steel in the outer layer of the roll body, the semi-steel molten steel in the middle layer, and the molten iron in the core, for use;

[0046] S11: Smelting of the outer high-speed molten steel, the outer high-speed molten steel contains the following components: by mass%, C 1.4-2.2%, Si 0.6-1.7%, Mn 0.5-2.0%, V 3.0-4.8%, Ni 0.2-0.7 %, Cr 2.2-5.3%, Nb 0.5-1.0%, Sr 0.001-0.03%, Mo 3.3-6.7%, W 0.03-1.5%, Nd 0.001-0.1%, Zr 0.5-1.5%, N 0.1-0.5%, The balance is composed of Fe and unavoidable impurities; after smelting, 0.2-0.5% of the mass fraction of the outer layer of high-speed steel is added with a modifier, and it is modified at 1640-1660°C. The particle size of the modifier is ≤0.3mm, and the modifier Including silicon bismuth, silicon z...

Embodiment 1

[0056] A preparation method of a high-speed steel roll, specifically comprising the following steps:

[0057] S1: Melting process, three intermediate frequency furnaces are used to melt the high-speed molten steel in the outer layer of the roll body, the semi-steel molten steel in the middle layer, and the molten iron in the core, for use;

[0058] S11: The outer high-speed molten steel is smelted, and the outer high-speed molten steel contains the following components: by mass %, C 1.8%, Si0.9%, Mn 1.1%, V 3.4%, Ni 0.4%, Cr 2.6%, Nb 0.7% , Sr 0.005%, Mo 4.7%, W0.2%, Nd 0.02%, Zr 0.9%, N 0.3%, the balance is composed of Fe and unavoidable impurities; after smelting, add 0.3% of the mass fraction of the outer layer of high-speed steel The modification agent is modified at 1650°C. The particle size of the modification agent is ≤0.3mm. The modification agent includes silicon bismuth, silicon zirconium and silicon germanium with a mass ratio of 13:20:1. The modification agent is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com