Pipe billet cooling centering machine

A technology of centering machine and tube blank, which is applied in the direction of guiding/positioning/aligning device, etc., can solve the problems of small reduction of alloy steel perforation, uneven wall thickness of the front end of the capillary, and increased heating equipment, etc., to achieve simple processing, social Significant benefits, reducing smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

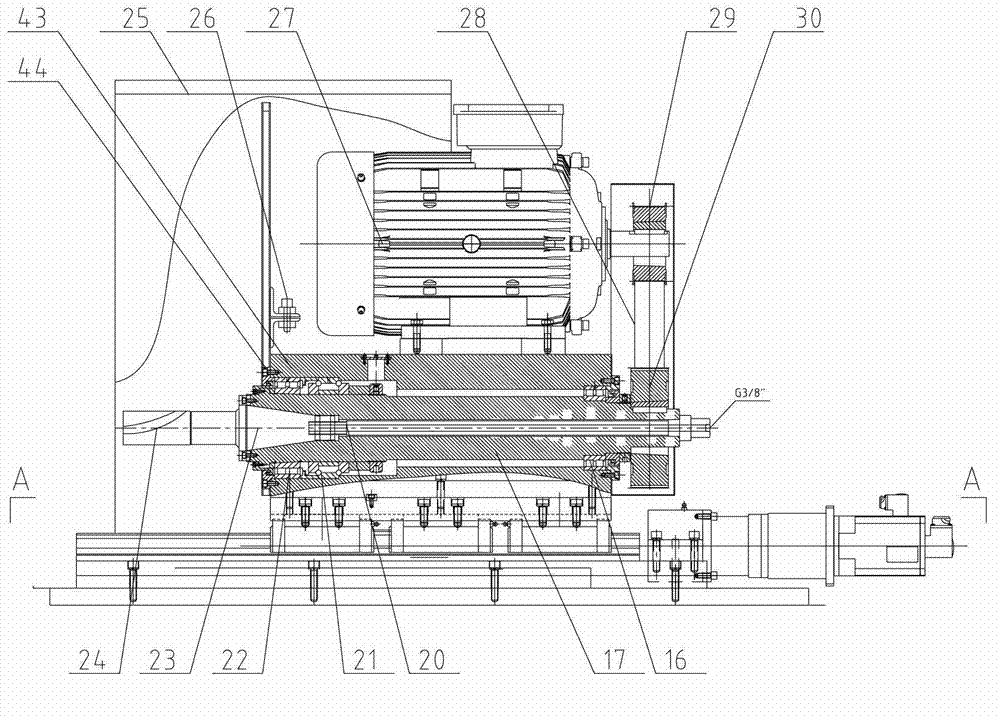

[0035] The specific embodiment of the present invention is shown in the accompanying drawings, which is composed of a hydraulic clamp 1, a host machine 2, an emulsion cooling system 3, a base 4, a magnetic chip conveyor 5, a waste chip collection frame 6, a position detection device 7 and a hydraulic system 8 It is composed of; it is characterized in that the hydraulic clamp 1 is mounted on the front of the base 4 through fastening bolts and positioning pins; the main engine 2 is fixed on the upper part of the base 4 through fastening bolts and positioning keys; the magnetic chip conveyor is placed on the The iron filings processed from the tube blank during centering are collected under the base 4; the emulsion cooling system 3 is connected to the rear of the tie rod 20 on the host machine 2 through a rotary joint to provide coolant to the drilling tool; the position detection device 7 is fixed The end is fixed on the base, and the mobile end is fixed on the sliding seat 12 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com