Silicon alloy and graphene composite material and preparation method thereof

A technology of composite materials and silicon alloys, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as the collapse of silicon lattice structure, the deactivation of active materials, and the pulverization of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

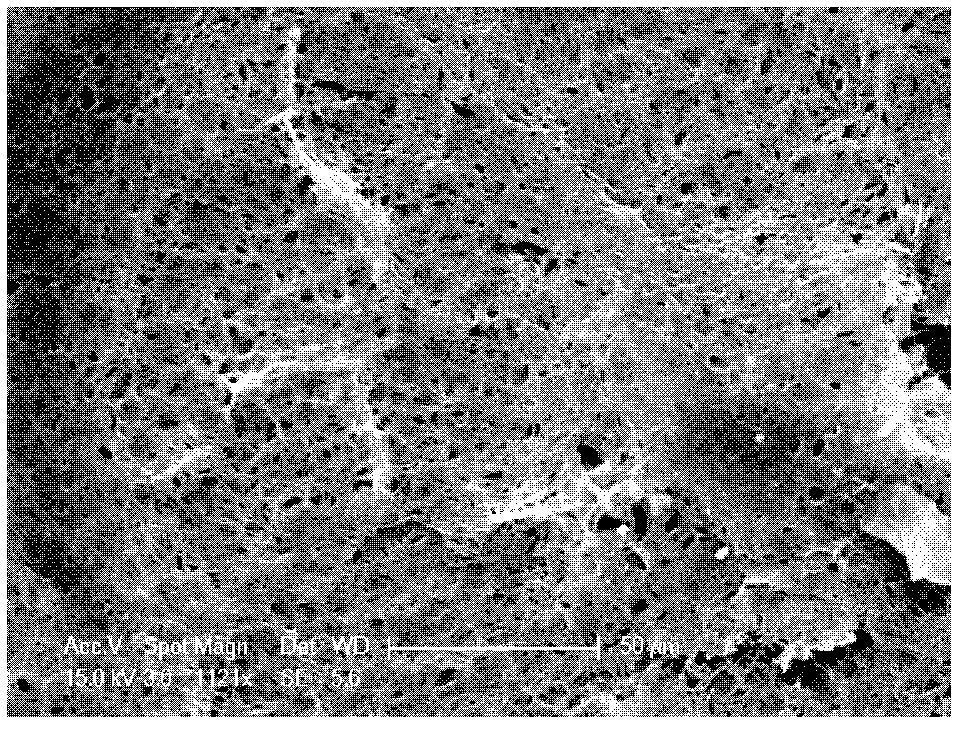

Image

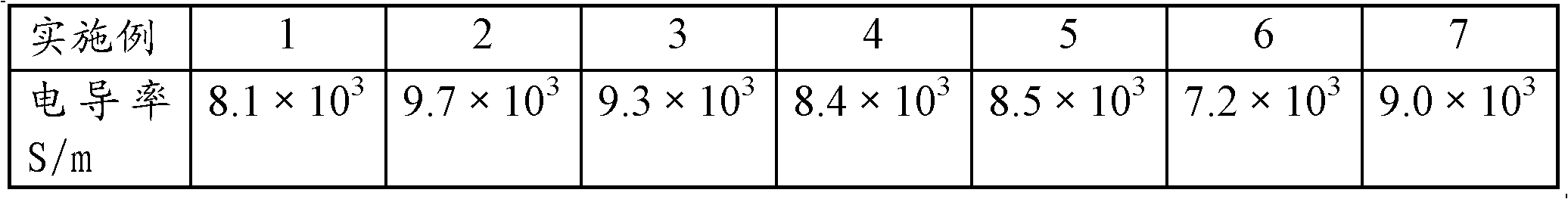

Examples

preparation example Construction

[0034] The preparation method of above-mentioned silicon alloy of one embodiment, graphene composite material, comprises the steps:

[0035] S10. Providing or preparing silicon alloy micro-nano particles and graphite oxide.

[0036] The silicon alloy micro-nano particles have a particle diameter of 1 nm to 100 nm.

[0037] The metal in the silicon alloy micro-nano particle is nickel, iron, copper, magnesium, cobalt or aluminum, and the mass ratio of the metal is 1%-30%.

[0038] Generally, a high-energy ball mill can be used to grind silicon alloy (Ni-Si, Fe-Si, Cu-Si, Mg-Si, Co-Si, Al-Si) powder to obtain silicon alloy micronano particles with a particle size of 1nm to 100nm. particles.

[0039] Afterwards, the surface of the silicon alloy micro-nano particle is treated with hydrochloric acid, so as to wash away the dirt on the surface of the silicon alloy micro-nano particle.

[0040] Generally, graphite oxide can be prepared from graphite by the Hummers method, that is, ...

Embodiment 1

[0063] (1) Graphite: 99.5% purity.

[0064] (2) Graphite oxide: Add 50-mesh graphite powder with a purity of 99.5%, potassium persulfate and phosphorus pentoxide into concentrated sulfuric acid at 75°C according to a mass ratio of 2:1:1, stir evenly, cool naturally, and wash until medium After drying, the pretreated mixture is obtained. Add the pretreated mixture into concentrated sulfuric acid, then add potassium permanganate, keep the temperature below 20°C, then add deionized water in an oil bath at 35°C for 2 hours, add hydrogen peroxide for reaction after 15 minutes, filter with suction, and collect the solid . Finally, the above solid was washed with dilute hydrochloric acid and dried to obtain graphite oxide.

[0065] (3) Grinding silicon alloy (Ni—Si alloy, 30% Ni) powder by a high-energy ball mill to obtain silicon alloy micro-nano particles, and treating the surface of the obtained silicon alloy micro-nano particles with hydrochloric acid.

[0066] (4) Composite o...

Embodiment 2

[0071] (1) Graphite: 99.5% purity.

[0072] (2) Graphite oxide: with embodiment 1.

[0073] (3) Grinding the silicon alloy (Cu—Si, 30% Cu) powder by a high-energy ball mill to obtain silicon alloy micro-nano particles, and treating the surface of the obtained silicon alloy micro-nano particles with hydrochloric acid.

[0074] (4) Composite of silicon alloy micronanoparticles and graphene oxide: add the graphite oxide prepared in (2) into water for ultrasonic dispersion to form a graphene oxide solution uniformly dispersed in a single layer, mix the above two, and silicon The mass ratio of the alloy to the graphene oxide is 1:10, vigorously stirred at room temperature for 0.5 h, and dried in vacuum to obtain evenly dispersed graphene oxide-coated silicon alloy micro-nano particles.

[0075] (5) Thermal reduction in an atmosphere containing a reducing gas: Put the silicon alloy micro-nano particles coated with graphene oxide obtained in (4) into a tube furnace passing through c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com