Preparation method of Al3Ti particle reinforced 2618 aluminium alloy composite

A composite material and particle-reinforced technology, which is applied in the field of preparation of Al3Ti particle-reinforced 2618 aluminum alloy composite materials, can solve the problems that the 2618 alloy cannot meet industrial applications, use restrictions, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment one: Preparation of 2618 alloy: According to the ratio of each alloy element in Table 1, Cu element is 2.3wt.%; Mg element is 1.6wt.%; Fe element is 1.1wt.%; Ni element is 1.1wt.%; Al element is the balance , you must prepare Al-50 wt.%Cu alloy 4.60g; Al-8 wt.%Fe13.75g; Al-8 wt.%Ni alloy 13.75g and 1.60g pure magnesium and 66.30g pure aluminum.

[0021] first at 720 Next, melt pure aluminum in a pit furnace of model SG2-1.5-10 and hold it for 10 minutes, then wrap Al-8 wt.%Fe, Al-8 wt.%Ni and Al-50 wt.% with aluminum foil Cu is added to the molten aluminum, and 3~5g of homemade 30NaCl-45KCl-25Na is quickly sprinkled on the surface of the alloy 3 AlF 6 (weight ratio, the same below) Covering agent, keep warm for 10 minutes and stir, use a bell jar to press the magnesium block with the surface oxide scale removed into the alloy liquid; after it is completely melted, sprinkle a layer of covering agent (2g ), after standing for 3~5 minutes, remove the cover...

Embodiment 2

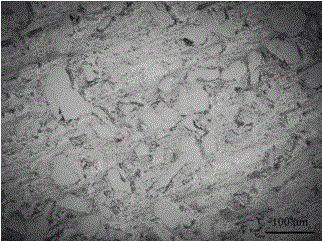

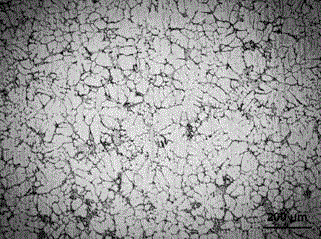

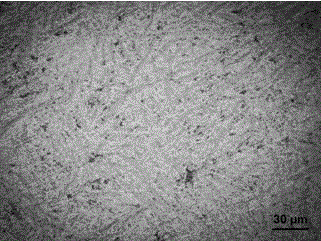

[0022] Embodiment two: Preparation of Al with 0.5% Ti content 3 Ti particle reinforced 2618 aluminum alloy composite material: the molten Al-10 wt.%Ti master alloy is uniformly cast on a high-speed turbine with a rotation speed of 500 rpm in a small stream, and the master alloy liquid is rapidly absorbed by the centrifugal force of the turbine Throw it into room temperature water to obtain a rapidly solidified Al-10 wt.%Ti master alloy; the microstructure of the Al-10 wt.%Ti master alloy after high-speed rotating water cooling is as follows image 3 As shown, it can be seen that compared with before water cooling, Al 3 The Ti phase is obviously refined.

[0023] The total weight of the prepared sample (the total weight of Al-10 wt.%Ti master alloy + 2618 alloy) is 100g, take 5g of dried turbine high-speed rotating water-cooled Al-10 wt.%Ti master alloy particles, prepare the rest according to Table 1 For alloying elements, 95g of 2618 alloy must be prepared, specifically 4.6...

Embodiment 3

[0025] Embodiment three: Preparation of Al with 1.0% Ti content 3 Ti particle reinforced 2618 aluminum alloy composite material: the molten Al-10 wt.%Ti master alloy is uniformly cast on a high-speed turbine with a speed of 500 rpm in a small stream, and the master alloy liquid is quickly thrown into room temperature water. A rapidly solidified Al-10 wt.%Ti master alloy was obtained.

[0026] The total weight of the prepared sample (the total weight of Al-10 wt.%Ti master alloy + 2618 alloy) is 100g, take 10g of dried turbine high-speed rotating water-cooled Al-10 wt.%Ti master alloy particles, and prepare the rest according to Table 1 For alloying elements, 90g of 2618 alloy must be prepared, specifically 4.60g of Al-50Cu alloy, 13.75g of Al-8 wt.%Fe, 13.75g of Al-8 wt.%Ni alloy, 1.60g of pure magnesium and 56.30g of pure aluminum.

[0027] Press the Al-10Ti intermediate alloy particles wrapped in aluminum foil into the molten 2618 alloy liquid below the surface of the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com