Packaging method for cerium-doped halogenated lanthanum scintillation crystal

A technology of scintillation crystal and packaging method, applied in the direction of measurement device, radiation measurement, instrument, etc., can solve the problems of easy deliquescence, poor temperature shock resistance, low performance, etc., and achieves improved service life, improved light output, energy resolution rate improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings. The following implementation cases are some examples illustrating the innovative content of the present invention, and the implementation cases cannot simply be regarded as limitations on the present invention.

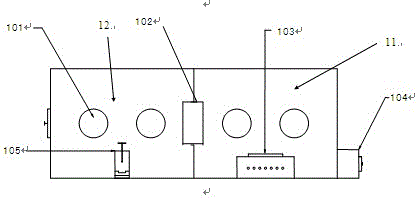

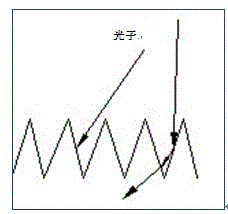

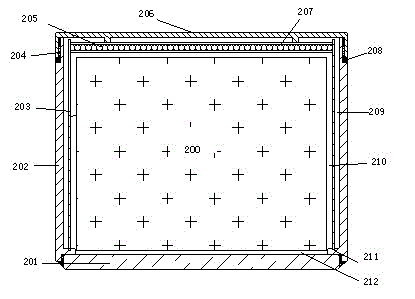

[0011] figure 1 Disclosed are a processing environment and method for a cerium-doped lanthanum halide scintillation crystal. The specific steps are as follows: respectively place the crystal processing and packaging tools in two chambers of a vacuum glove box with a humidity of 3ppm and an oxygen content of no more than 5ppm. The crystal enters the chamber 11 where the small polishing grinder 103 is located from the transition chamber 104 for grinding and polishing to remove the corrosion layer on the surface of the crystal, and then use 320-grit sandpaper to roughen the side and back of the crystal randomly. Use 120-grit sandpaper to roughen the light-emittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com