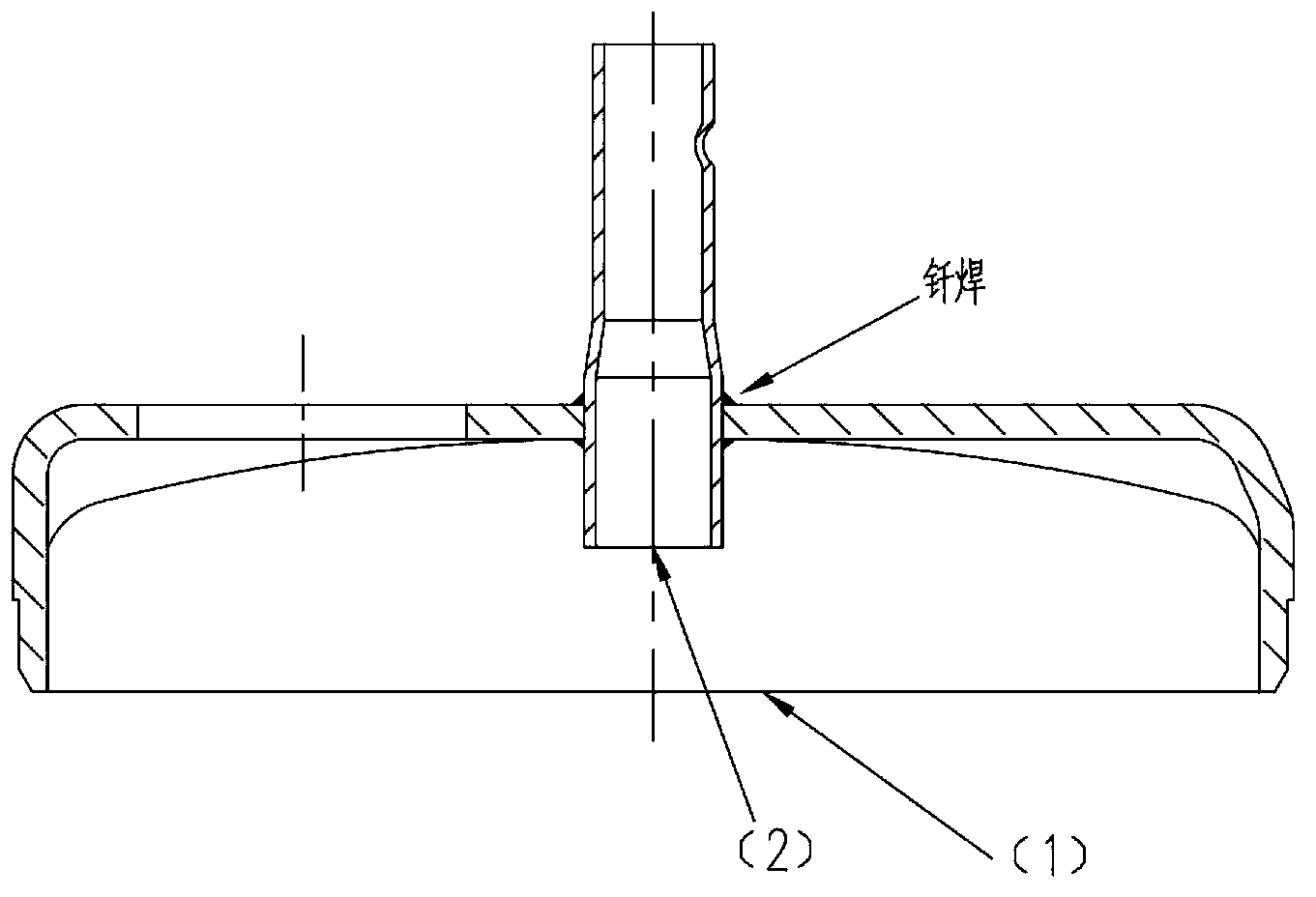

Solder composition and preparing method and application thereof

A technology of composition and welding method, which is applied in the direction of welding equipment, welding/welding/cutting items, welding/cutting medium/material, etc., which can solve the problem of weld reliability but can not solve fatigue damage and weld failure, and can not solve brazing Permeability and weld leakage rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] According to the method for preparing solder composition of the present invention, prepare solder composition, concrete steps are as follows:

[0084] 59 parts by weight of copper, 39 parts by weight of zinc and 2 parts by weight of tin were uniformly mixed, and at least one selected from silicon and phosphorus was not introduced during the preparation process, thereby obtaining a solder composition.

Embodiment 2

[0086] According to the method for preparing solder composition of the present invention, prepare solder composition, concrete steps are as follows:

[0087] 59 parts by weight of copper, 39 parts by weight of zinc and 2 parts by weight of indium were uniformly mixed, and at least one selected from silicon and phosphorus was not introduced during the preparation process, thereby obtaining a solder composition.

Embodiment 3

[0089] According to the method for preparing solder composition of the present invention, prepare solder composition, concrete steps are as follows:

[0090] 55 parts by weight of copper, 40 parts by weight of zinc and 5 parts by weight of silver are uniformly mixed, and at least one selected from silicon and phosphorus is not introduced during the preparation process, thereby obtaining a solder composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com