Composite material containing nitride and submerged nozzle applying composite material

A composite material and nitride-containing technology, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems that the corrosion resistance does not meet the requirements of continuous casting production, it is easy to burst, and affects continuous casting operations, etc. , to achieve the effects of improving erosion resistance and thermal shock resistance, best erosion resistance and thermal shock resistance, and excellent mold slag erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

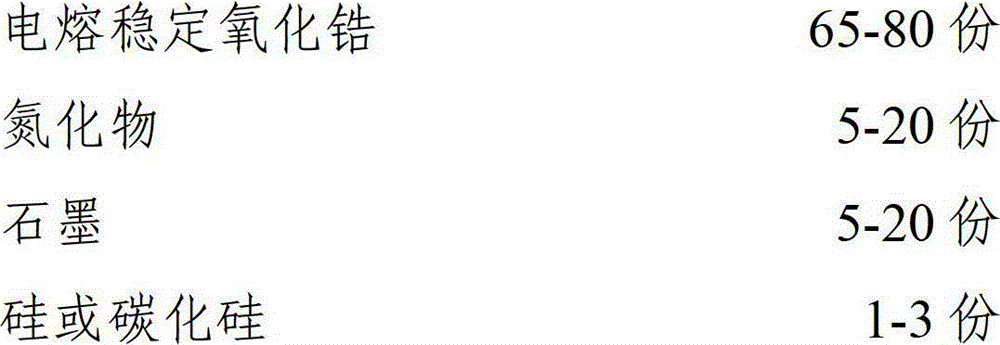

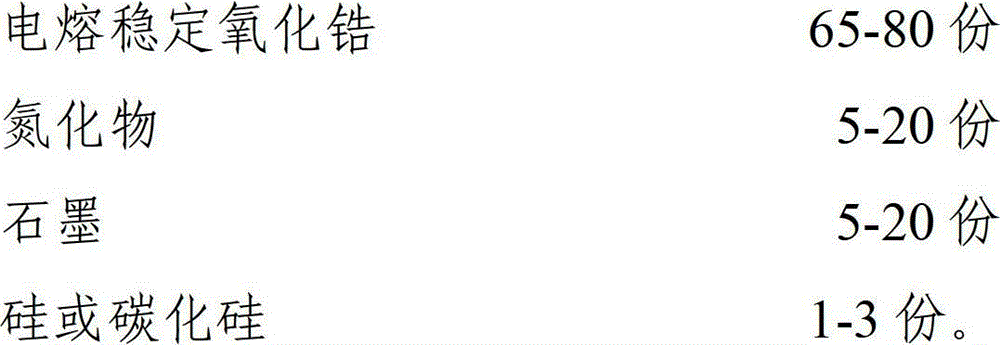

[0027] Slag wire material: 80% fused stabilized zirconia (Zhenzhong Fused Zirconia Industry Co., Ltd., wherein the mass content of zirconia is 92-97%, and the fused stabilized zirconia within this content range can obtain composites with the same technical effect material), graphite 5%, Sialon 12% (purchased from Tangshan Hexagon Silicon Carbide Co., Ltd., where N is 14-30% by mass, and Sialon within this content range can achieve the same technical effect), metal silicon powder 3 %, plus 10% phenolic resin (both by mass ratio). Graphite is flake graphite with a carbon content of 99%.

[0028] The process of granulation and mixing is carried out in the granulator. When controlling the granulation, the granulation is controlled according to the low speed of 80r / min for 8 minutes, the medium speed of 500r / min for 5 minutes, and the high speed of 800r / min for 10 minutes. The material temperature in the granulation equipment is controlled is 55°C. After granulation, kneading and...

Embodiment 2

[0030] Slag wire material: 65% fused stabilized zirconia, 12% graphite, 20% Sialon, 3% metal silicon powder, plus 10% phenolic resin. Graphite is flake graphite with a carbon content of 98%.

[0031] The process of granulation and mixing is carried out in the granulator. When controlling the granulation, the granulation is controlled according to the low speed of 100r / min for 8 minutes, the medium speed of 550r / min for 5 minutes, and the high speed of 800r / min for 12 minutes. The material temperature in the granulation equipment is controlled at 40°C. After granulation, mixing and drying, it is compounded with the aluminum-carbon body, isostatically pressed (molding pressure 100MPa), sealed, and fired at 1100°C for 25 hours in a non-oxidizing atmosphere to produce an immersion type Nozzle has been used in 16 furnaces in a steel factory for 12 hours, and there is no phenomenon of bursting, diameter expansion, erosion, etc., which meets the customer's use requirements.

Embodiment 3

[0033] Slag wire material: 70% fused stabilized zirconia, 20% graphite, 5% sialon, 3% aron, 2% silicon carbide powder, plus 14% phenolic resin. Graphite is flake graphite with a carbon content of 99.5%.

[0034] The process of granulation and mixing is carried out in the granulator. When controlling the granulation, the granulation is controlled according to the low speed of 80r / min for 8 minutes, the medium speed of 600r / min for 5 minutes, and the high speed of 1000r / min for 15 minutes. The material temperature in the granulation equipment is controlled at 65°C. After granulation, mixing and drying, it is compounded with the aluminum-carbon body, isostatically pressed (molding pressure 80MPa), sealed, and fired at a temperature of 1000°C for 30 hours in a non-oxidizing atmosphere. Nozzle has been used in 20 furnaces in a steel factory for 8 hours, and there is no phenomenon of bursting, diameter expansion, erosion, etc., which meets the customer's use requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com