Conductive copper water jacket and casting process thereof

A casting process and technology of copper water jacket, applied in the field of metallurgy, can solve the problems of poor compactness, short service life, high temperature of water jacket, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure and casting process of the copper water jacket of the present invention will be described in detail below through specific examples.

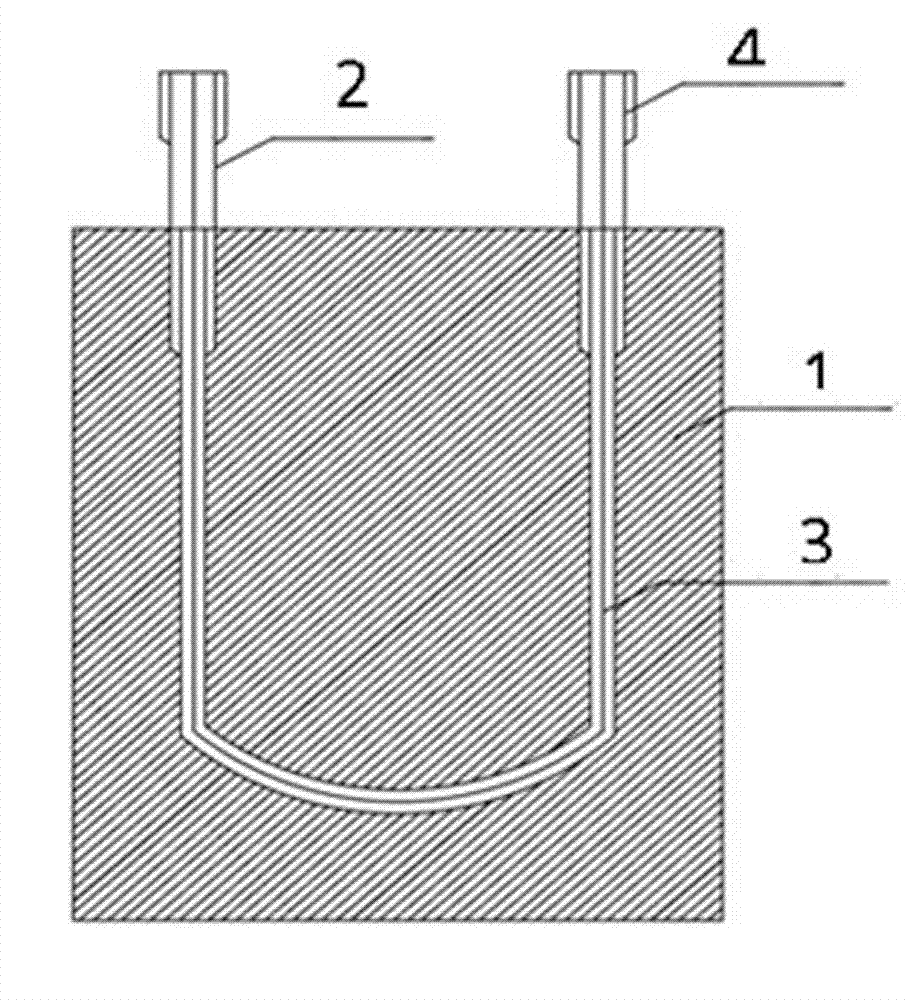

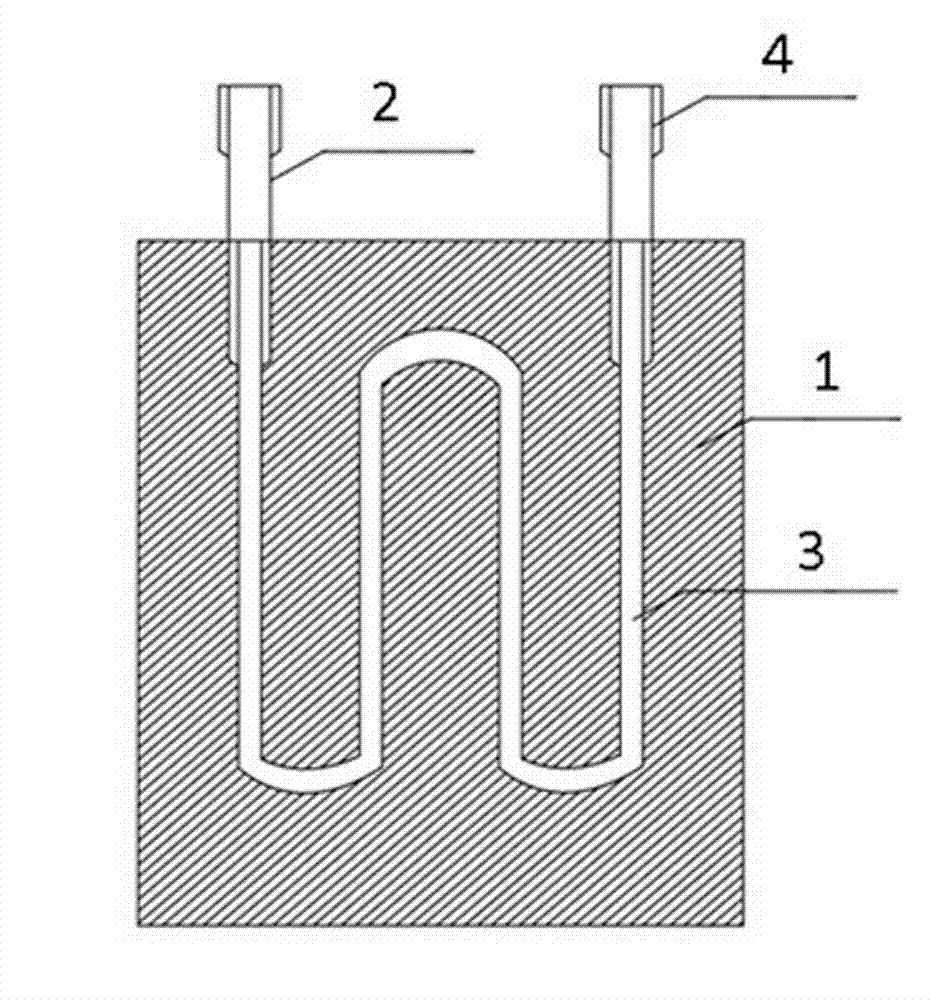

[0022] (1) Preparation of sand core cooling water pipe: Use clay core sand to prepare a "U" or "W" cooling water channel, and paint high temperature resistant casting paint on the outside of the cooling water channel.

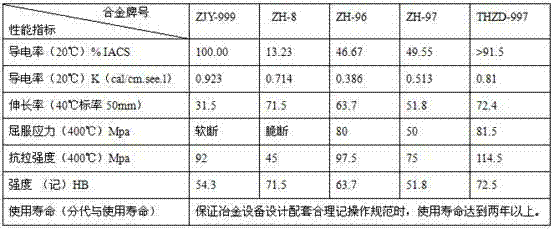

[0023] (2) Preparation of deoxidized copper alloy water: firstly adopt the traditional "wood insertion reduction method" to deoxidize molten copper water, then add phosphorus, magnesium, arsenic, and yttrium in sequence to obtain molten copper alloy water; the copper alloy The mass percent content of each doping component in water is:

[0024] Phosphor bronze: 0.15-0.25%, magnesium: 0.001-0.002%, arsenic: 0.001-0.002%, yttrium: 0.015-0.020%.

[0025] In order to further improve the quality of copper alloy water, when smelting copper water, an inert gas is introduced into the refining furnace to remove oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com