Preparation method of phosphotungstic acid-polyimide composite proton exchange membrane

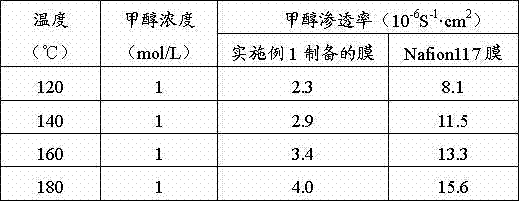

A technology of proton exchange membrane and polyimide, which is applied in the field of preparation of phosphotungstic acid-polyimide composite proton exchange membrane, can solve the problems of heteropolyacid loss and other problems, and achieve the improvement of proton conductivity and the reduction of methanol permeability , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1), 4.79 grams of diphenyl ether diamine and 5.21 grams of pyromellitic dianhydride were dissolved in 90 g of dimethyl sulfoxide to form polyamic acid solution A;

[0029] 2) Solution A was stirred in a nitrogen atmosphere for 1 hour, heated to 65°C, added 2.17 g of concentrated phosphoric acid with a concentration of 85.54% by mass, 2.43 g of sodium tungstate and 8.18 g of water, and stirred for 2 hours to form a uniform solution B ;

[0030] 3) Heat the solution B to 120°C in a vacuum oil bath, continue to stir until all the water in the solution evaporates, and cool to room temperature to obtain a uniform solution C;

[0031] 4), pour solution C on a glass plate, place it flat in a drying oven, and heat it at 120°C, 150°C, 200°C, 250°C and 300°C for 12h, 1h, 1h, 1h and 1h in sequence, after cooling and falling off , that is to obtain phosphotungstic acid-polyimide composite proton exchange membrane.

[0032] When used, the membrane was soaked in deionized wate...

Embodiment 2

[0034] 1), 2.4 grams of diphenyl ether diamine and 2.6 grams of pyromellitic dianhydride were dissolved in 57.5 g of dimethyl sulfoxide to form polyamic acid solution A;

[0035] 2) Stir the solution A in a nitrogen atmosphere for 0.5h, raise the temperature to 60°C, add 1.17g concentrated phosphoric acid, 1.14g sodium tungstate and 5.23g water to the solution A, and form a uniform solution B after stirring for 3 hours;

[0036] 3) Heat the solution B in a vacuum oil bath to 110°C, continue to stir until all the water in the solution evaporates, and cool to room temperature to obtain a uniform solution C;

[0037] 4), pour solution C on a glass plate and place it flat in a drying oven, heat at 120°C, 150°C, 200°C, 250°C and 280°C for 12h, 1h, 1h, 1h and 1h in sequence, after cooling and falling off That is, the phosphotungstic acid-polyimide composite proton exchange membrane is obtained.

Embodiment 3

[0039] 1), 6.23 grams of diphenyl ether diamine and 6.77 grams of pyromellitic dianhydride were dissolved in 131.44 g of dimethyl sulfoxide to form polyamic acid solution A;

[0040] 2) Stir the solution A for 1 hour in a nitrogen atmosphere, raise the temperature to 70°C, add 3.26 g of concentrated phosphoric acid, 2.79 g of sodium tungstate and 11.95 g of water to the solution A, and stir at this temperature for 1.5 hours to form a uniform Solution B;

[0041] 3) Heat the solution B in a vacuum oil bath to 115°C, continue to stir until all the water in the solution evaporates, and cool to room temperature to obtain a uniform solution C;

[0042] 4), pour solution C on a glass plate and place it flat in a drying oven, heat at 120°C, 150°C, 200°C, 250°C and 290°C for 12h, 1h, 1h, 1h and 1h in sequence, after cooling and falling off That is, the desired phosphotungstic acid-polyimide composite proton exchange membrane is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com