Abrasive for moisture blasting, and manufacturing method for same

A sandblasting, wet-type technology, applied in abrasives, manufacturing tools, adhesive types, etc., can solve problems such as deburring performance decline, slurry instability, loss, etc., to achieve good impact resistance, suppression of floating, excellent dispersion The effect of resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] A 5L polymerization vessel equipped with a stir bar and a thermometer was filled with 2500 parts by weight of deionized water, and 50 parts by weight of magnesium pyrophosphate was dispersed therein.

[0122] The mixture liquid was added to the monomer mixture by adding 8 parts by weight of 2'-azobis(2,4-dimethylvaleronitrile), 8 parts by weight of benzoyl peroxide and As a polymerization inhibitor, 4.7 parts by weight of phenol-based antioxidant (manufactured by Sumika Chemtex Co., Ltd.: SUMILIZER BBM-S) was obtained by dissolving, and the monomer mixture was 1400 parts by weight of methacrylic acid Methyl ester, 80 parts by weight of ethylene glycol dimethacrylate and 80 parts by weight of poly(ethylene glycol-propylene glycol) monomethacrylate (manufactured by Nippon Oil & Fats Co. Ltd.: Blemmer 50PEP-300, "m "Is 3 to 4, "n" is 2 to 3) and 0.8 parts by weight of caprolactone EO (ethylene oxide) modified phosphoric acid dimethacrylate mixture, and the monomer mixture is ...

Embodiment 2

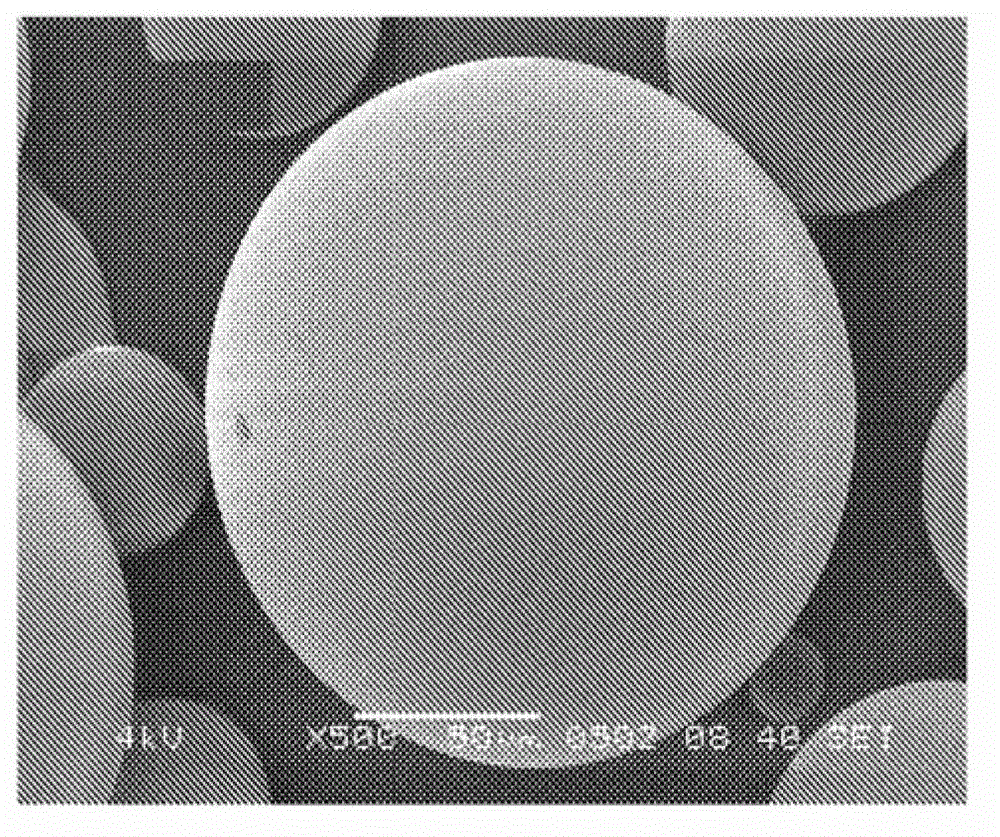

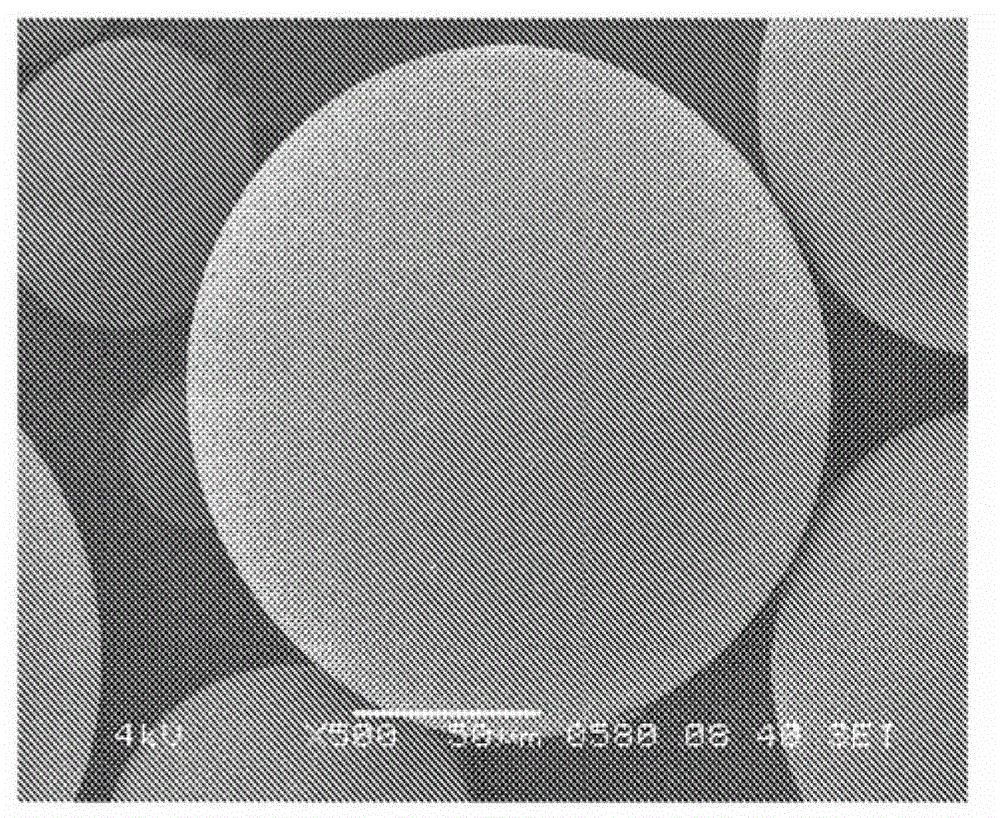

[0132] Except that the stirring cycle during drying was changed to a cycle of stirring for 1 minute and allowing it to stand for 29 minutes, the same procedure as in Example 1 was performed to obtain dried polymer particles. The time required for drying is 12 hours. The number of stirrings until drying was 240 times. The number of stirring times for 1kg polymer particles is (240 times / 1.56kg≈) 154 times. When using a scanning electron microscope to observe the dried polymer particles, such as image 3 As shown, it can be confirmed that the polymer particles are particles all having a smooth surface, and no adhesion of latex or the like is seen therein.

[0133] The number of latex bodies etc. adhering to the surface of the dried polymer particles (average value of 5 fields of view) is 5 (⊙).

[0134] The float of the particles is less than 2mm (⊙).

[0135] The time required for particle addition was 22 hours (○).

[0136] The number of items with remaining burrs evaluated by the d...

Embodiment 3

[0139] The same process as in Example 1 was performed except that stirring was not performed through a dryer in the drying step to obtain dried polymer particles. The time required for drying is 27 hours. The number of stirrings until drying is 0 times.

[0140] The number of latex bodies etc. adhering to the surface of the dried polymer particles (average of 5 fields of view) is 2 (⊙).

[0141] The float of the particles is less than 1mm (⊙).

[0142] The time required for particle addition was 27 hours (○).

[0143] The number of items with remaining burrs evaluated by the deburring effect is 10 or less (○).

[0144] The number of articles with cracks and defects evaluated by the cracks and defects of the articles after grinding was 5 or less (○).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com