Aluminum steel dissimilar metal laser welding-brazing welding method and filled powder

A technology of dissimilar metals and welding methods, used in laser welding equipment, welding media, welding equipment and other directions, can solve the problems of difficult to form welded joints, reduced mechanical properties of welded joints, poor welding seam forming, etc., to improve the absorption rate and Laser welding speed, good weld formation, effect of increasing spread width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 5052, 5056, 6063 aluminum alloys and galvanized steel ST04Z were used for lap joint tests. The specifications of 5052, 5056, 6063 aluminum alloys and galvanized steel ST04Z were all 150mm×60mm×1mm. When the laser power is 1.5~2.5KW, the welding speed is 0.4~1.2m / min, the defocus is -2~+2mm, and the argon gas protection is 15L / min, the welding seam with beautiful shape and excellent performance can be obtained. The maximum mechanical resistance is 208Mpa, which is about 95% of the base metal.

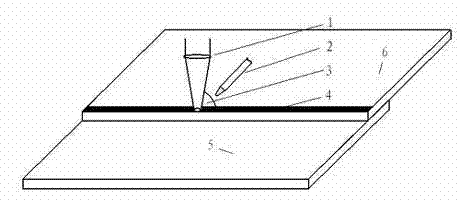

[0021] Such as figure 1 As shown, the aluminum plate is on the upper steel plate, and the lap length is 4-6mm. The laser beam 1 is vertically injected into the aluminum side, 0-0.5mm away from the edge of the aluminum side, and the angle between the shielding gas nozzle 2 and the beam is 30°-60°. Powder 4 is suitable for covering the surface gloss of the aluminum alloy, and the coating width is 2-4mm.

[0022] figure 2 It is the topography of 5052 aluminum alloy and steel l...

Embodiment 2

[0024] Use 5052 aluminum alloy and galvanized steel plate ST04Z for laser butt fusion brazing, the specification of 5052 aluminum alloy is 125mm×50mm×2mm, the specification of galvanized steel plate ST04Z is 125mm×50mm×1mm, the laser power is 1.7~3.0KW, and the welding speed is 0.4~1.2 m / min, defocus -2~+2mm, and argon protection of 15L / min, it can realize aluminum-steel dissimilar metal butt welding joints. Such as Figure 12 Shown is a schematic diagram of the method of powder coating and laser melting and brazing of aluminum alloys and steels with different thicknesses (thick aluminum and thin steel), such as Figure 12 As shown, the bottom surface of the aluminum plate and the bottom surface of the steel plate are assembled on the same plane without leaving a gap, the laser beam 1 is vertically injected into the aluminum side, and the distance from the edge of the aluminum side is 0-0.5mm, the angle between the protective gas nozzle 2 and the beam is 30°-60°, and the powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com