Method for preparing polycrystalline silicon film by carrying out induced crystallization on amorphous silicon film by using metallic copper under low temperature

A technology of amorphous silicon thin film and polycrystalline silicon thin film, which is applied in metal material coating technology, semiconductor devices, gaseous chemical plating, etc., can solve problems such as unsuitability, high material defect density, high grain boundary density, etc., and achieve compatibility Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

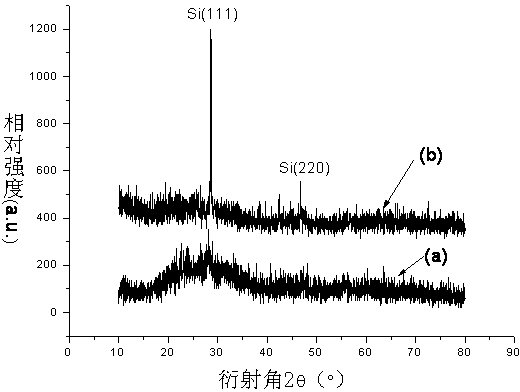

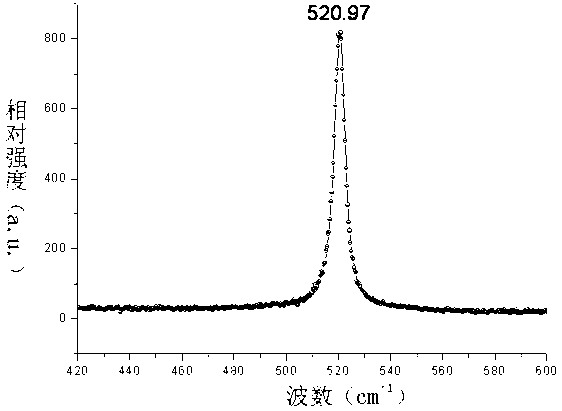

Examples

Embodiment

[0027] The process and steps in the embodiment of the present invention are as follows:

[0028] (1) Cut a piece of ordinary Corning glass into 1cm×1cm size, clean the surface dirt with Triton solvent, then ultrasonically clean it in acetone, absolute ethanol and deionized water for 15 minutes, and dry it with nitrogen;

[0029] (2) Deposit a layer of amorphous silicon (a-Si:H) film on the cleaned substrate by plasma-enhanced chemical deposition (PECVD), with a thickness of about 300nm. The substrate temperature during deposition is 250°C, and the deposition pressure is for 10 -5 Pa, gas glow pressure range 50Pa-200Pa, RF power supply 13.56MHz, gas source is silane with a purity of 99.999% (SiH 4 ), the purity of hydrogen used as dilute silane is 5N (99.999%), where H 2 The proportion of mixed gas is about 2%;

[0030] (3) Place the grown amorphous silicon thin film sample in an oxygen chamber for 5 h at room temperature, put it in a magnetron sputtering vacuum chamber, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com