Preparation method for tungsten carbide ceramic/heat-resisting alloy based heat-resisting and wear-resisting composite material

A technology of tungsten carbide ceramics and heat-resistant alloys, which is applied in the field of alloy material manufacturing, can solve problems such as increased residual stress, inability to prepare high heat-resistant and wear-resistant composite materials, and limited use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Taking the preparation of ZGM110 type (output: 5-8t / h, grinding disc diameter: 1100mm, rotation speed: 50r / min, power: 110KW) coal mill lining as an example, the invention will be further explained in conjunction with the drawings. The output of ZGM110 type :5~8t / h, grinding disc diameter: 1100mm, speed: 50r / min, power: 110KW.

[0027] A preparation method of tungsten carbide ceramic / heat-resistant alloy-based heat-resistant and wear-resistant composite material includes the following steps:

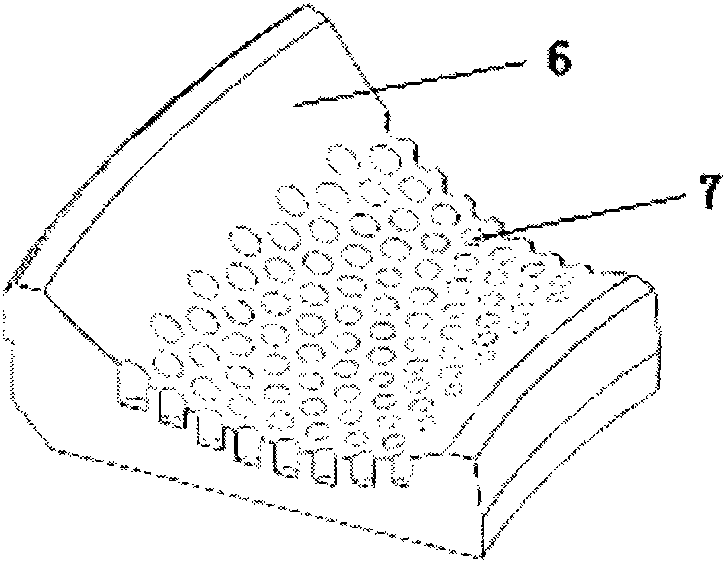

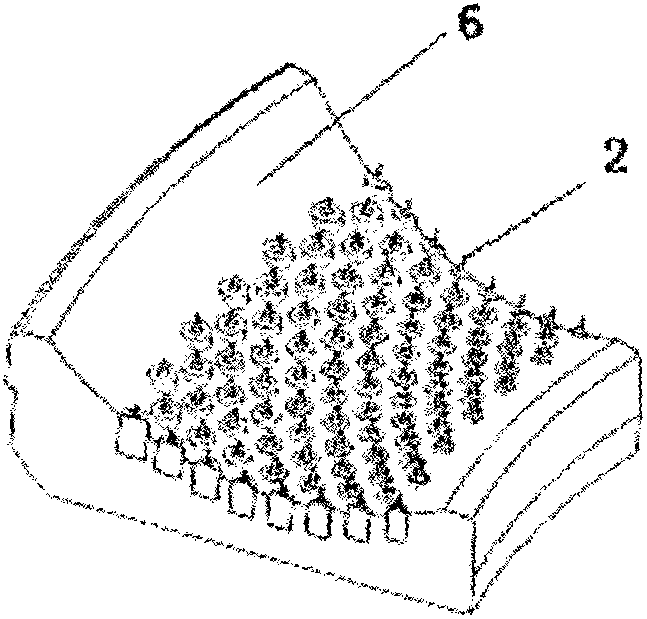

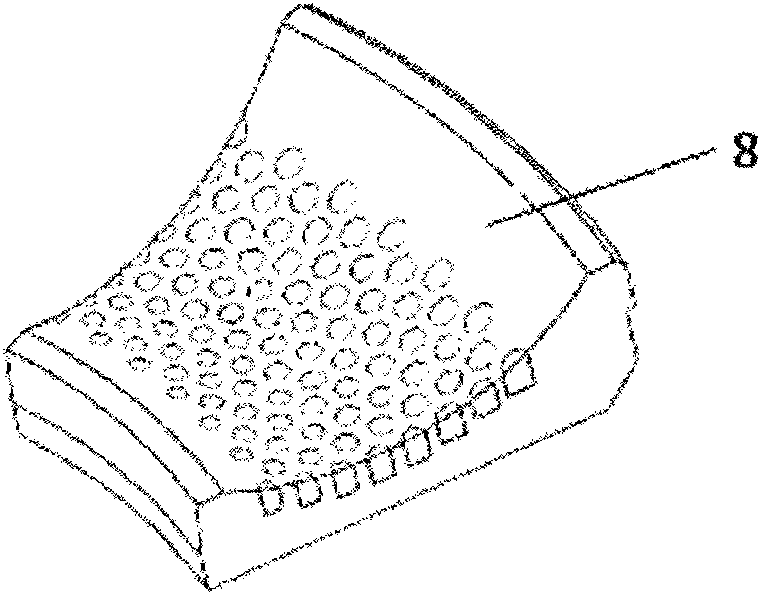

[0028] Step 1. Cut the tungsten carbide ceramic waste (1) into a composite reinforcement of the required shape and size, select YG8 tungsten carbide ceramic waste, and process it into a tungsten carbide ceramic with a size of Φ5mm×8mm through wire cutting Reinforcement, sandblasting after degreasing, and finally cleaning;

[0029] Step 2: Weld an iron nail (2) to one end of the tungsten carbide ceramic reinforcement treated in step 1, using a vacuum brazing process, and the brazing mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com