Oxide-based stable high-potential carrier for solid polymer fuel cell

An oxide and carrier technology, which is applied in the field of high-potential stable oxide carriers for polymer electrolyte fuel cells, can solve the problems of chain or dendritic forms of catalyst carriers that are not described.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] (in Sn 0.96 Sb 0.04 o 2-δ Catalyst loaded with 20wt% platinum catalyst)

[0083] First, in this example, using figure 2 The synthetic equipment used for the flame method is shown. Oxygen, air and propane flow from the image 3 The gas introduction parts 31 and 32 of the illustrated nozzle are introduced and mixed by a gas mixer 33 . The mixed gas is introduced into the stainless steel pipe 34 and passed through the burner 40 to form a chemical flame.

[0084] At the same time, a solution obtained by dissolving tin octoate and antimony octoate in mineral turpentine at a molar ratio of 0.96:0.04 is introduced into the solution introduction part 35 at 1 to 10 g per minute, and the air introduced in the carrier gas introduction part 36 , passing through mixer 37 and stainless steel pipe 38.

[0085] In addition, the solution is formed as a mist via a fluid nozzle, a gas nozzle and a retainer cap 39 and introduced into the chemical flame through a burner 40 . The te...

Embodiment 2

[0098] (SnO 2-δ carrier)

[0099] Also in this example, using figure 2The synthetic equipment used for the flame method is shown. The oxygen, air and propane flow rates for synthesis and formation of the chemical flame were the same as in Example 1. A solution obtained by dissolving tin octoate in mineral turpentine was misted and introduced into a chemical flame by the same method as in Example 1. The temperature of the chemical flame is raised to about 1600°C by the heat of combustion of propane and mineral turpentine, and in this chemical flame SnO is formed 2-δ powder.

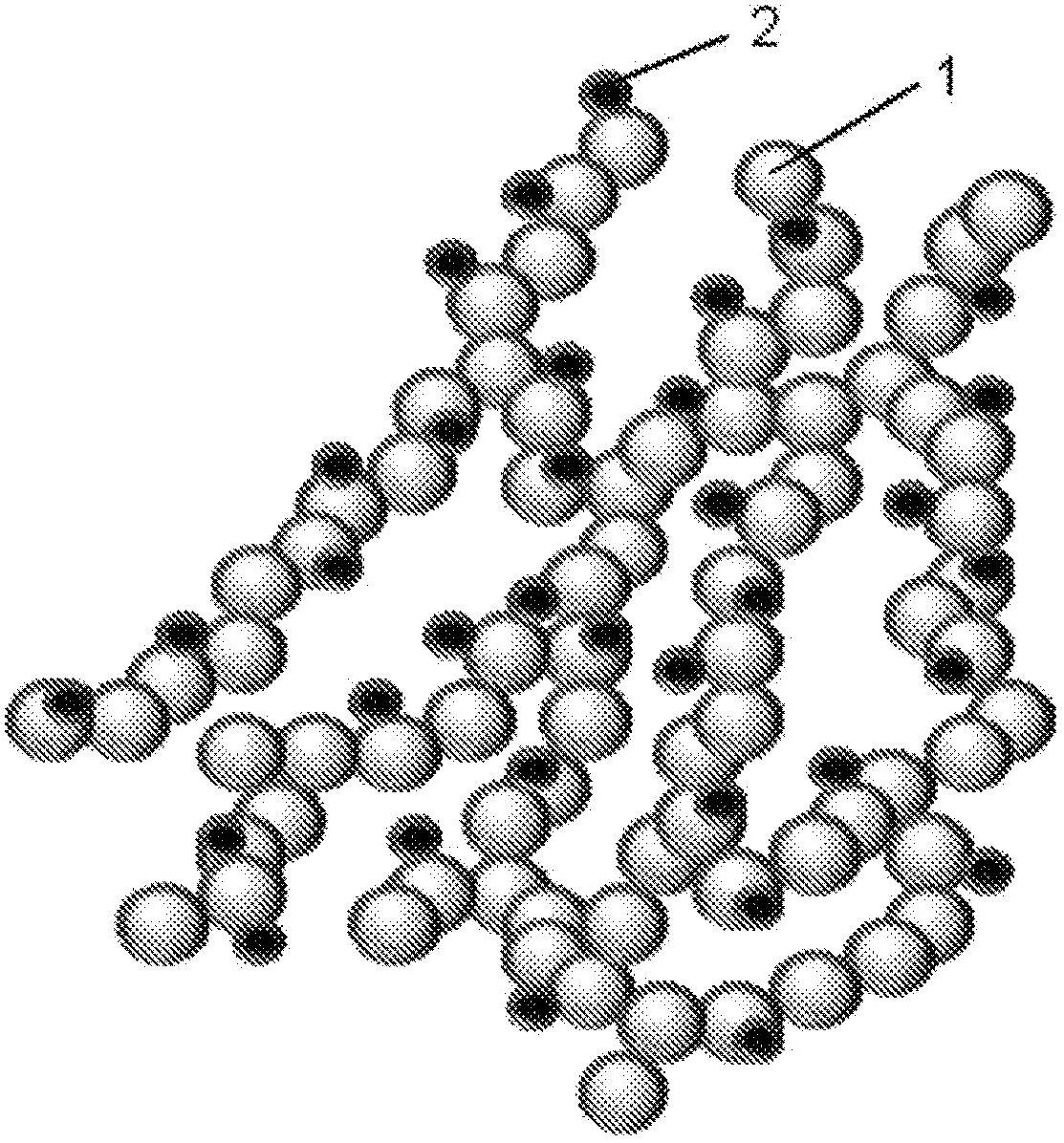

[0100] The formed powder is collected by collection filter 27 ( figure 2 ), and the amount of powder collected in 20 minutes of operation was 7 g. Evaluation of SnO by XRD 2-δ powder (see Figure 11 ), and the shape was observed by scanning transmission electron microscopy (STEM) (see Figure 12 ).

[0101] 0.5g of SnO 2-δ The powder is filled into a steel container with a rectangular hole of ...

Embodiment 3

[0103] (Ti 0.95 Nb 0.05 o 2-δ carrier)

[0104] Also in this example, using figure 2 The synthetic equipment used for the flame method is shown. The flow rate of oxygen, air and propane during synthesis and formation of chemical flame is the same as in Example 1. A solution obtained by dissolving titanium octoate and niobium octoate in mineral turpentine was misted by the same method as in Example 1 and introduced into a chemical flame. By the heat of combustion of propane and mineral turpentine, the temperature of the chemical flame is raised to about 1600°C, and in this chemical flame Ti is formed 0.95 Nb 0.05 o 2-δ powder.

[0105] The formed powder is collected by collection filter 27 ( figure 2 ), and the amount of powder collected in 20 minutes of operation was 7.5 g. Evaluation of Ti by XRD 0.95 Nb 0.05 o 2-δ powder (see Figure 13 ), and the shape was observed by scanning transmission electron microscopy (STEM) (see Figure 14 ). Production Ti 0.95 N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com