A method for extracting and separating natural saffron and its preparation for reducing blood lipid

A blood lipid-lowering drug, saffron technology, applied in the preparation of sugar derivatives, medical preparations containing active ingredients, drug combinations, etc., can solve the problem of low raw material utilization and production efficiency, consumption of extraction, elution solvents, and active substances Structural changes and other issues, to achieve the effect of low cost, good water solubility and strong permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

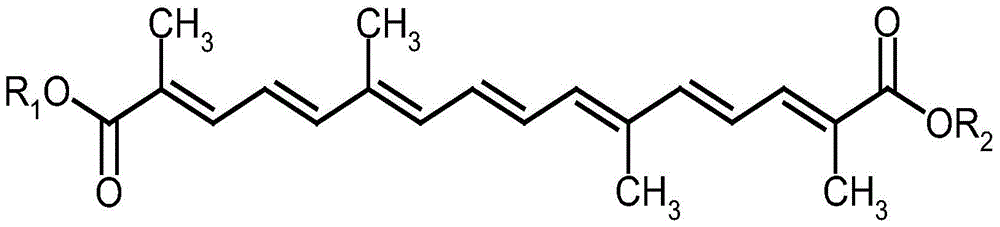

Image

Examples

Embodiment 1

[0082] Components and ratio of extractant (calculated by volume): Tween-80 0.1kg, tap water 100kg.

[0083] Take 5 kg of dried gardenia fruit, put it into the extraction tank, add 100 kg of extraction agent, cover and seal it, control the temperature at 50 ° C, and maintain 1 atmospheric pressure, stir intermittently for 5 minutes every hour, after leaching for 5 hours, filter out Add 50kg of extractant to the filtrate for the second extraction (5 hours). The two extracts are combined and filtered out with a total of 146kg after coarse filtration in a centrifuge, and cooled to 30°C; Filtration, operating temperature 25°C, pressure 0.3Mpa, to obtain 130kg of filtrate; the obtained filtrate was further filtered with a polysulfone ultrafiltration membrane PS-10 with a nominal molecular weight cut-off of 10,000 Daltons, operating temperature at 25°C, pressure 0.05Mpa, to obtain 121kg of filtrate ; The filtrate is adsorbed with HP-20 macroporous adsorption resin, and then eluted wi...

Embodiment 2

[0086] Components and ratio of extractant (calculated by weight): condensate of alkylphenol and ethylene oxide 1kg. Tap water 1000kg.

[0087] Take 50kg of dried gardenia fruit, 1000kg of extractant, and put it into an extraction tank, control the temperature at 55°C, stir intermittently for 10 minutes per hour, after leaching for 4 hours, filter out the filtrate, add 800kg of extractant to extract for 5 hours, two After the secondary extracts were combined, they were centrifugally filtered to remove impurities; after cooling 1750kg of filtrate to 30°C, filter it with a microfiltration membrane PP cotton with a pore size of 10μm, operating at a temperature of 30°C and a pressure of 0.5Mpa to obtain 1670kg of filtrate; filter the filtrate with a nominal molecular weight cut-off of 30,000 Dalton's roll-type polypropylene ultrafiltration membrane HPS-30 was further filtered at an operating temperature of 30°C and a pressure of 0.2Mpa to obtain 1600kg of filtrate; the filtrate was ...

Embodiment 3

[0090] Components and proportions of the extractant (calculated by weight): 0.2kg of condensation product of alkylphenol and ethylene oxide, 0.2kg of Tween-800.2kg, 250kg of tap water.

[0091] Take 30kg of dried gardenia fruit and 600kg of extraction solvent, put them into an extraction tank, control the temperature at 45°C, stir intermittently for 5 minutes per hour, after leaching for 6 hours, filter out the filtrate, then add 400kg of extraction agent to extract for 5 hours, twice After the extracts were combined, they were coarsely filtered by a centrifuge; after the filtrate 960kg was cooled to 30°C, it was filtered with a microfiltration membrane PP cotton with a pore size of 5 μm, the operating temperature was 30°C, and the pressure was 0.2Mpa to obtain a filtrate 910kg; the filtrate was filtered with a nominal molecular weight cut-off of 10000 Dalton's hollow fiber ultrafiltration membrane PS-10 was further filtered, the operating temperature was 30°C, and the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com