A kind of thread hole protective glue and its preparation method and application

A technology of protective glue and threaded holes, used in adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problems of odor and not easy to peel, achieve no volume shrinkage, good water resistance, good high temperature resistance sexual effect

Active Publication Date: 2022-06-03

上海仁速新材料有限公司

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Both of the above two light-curing protective adhesives use acrylate reactive diluents and polyurethane-modified acrylate resins, which have an odor and cross-link after light curing, making it difficult to peel off

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

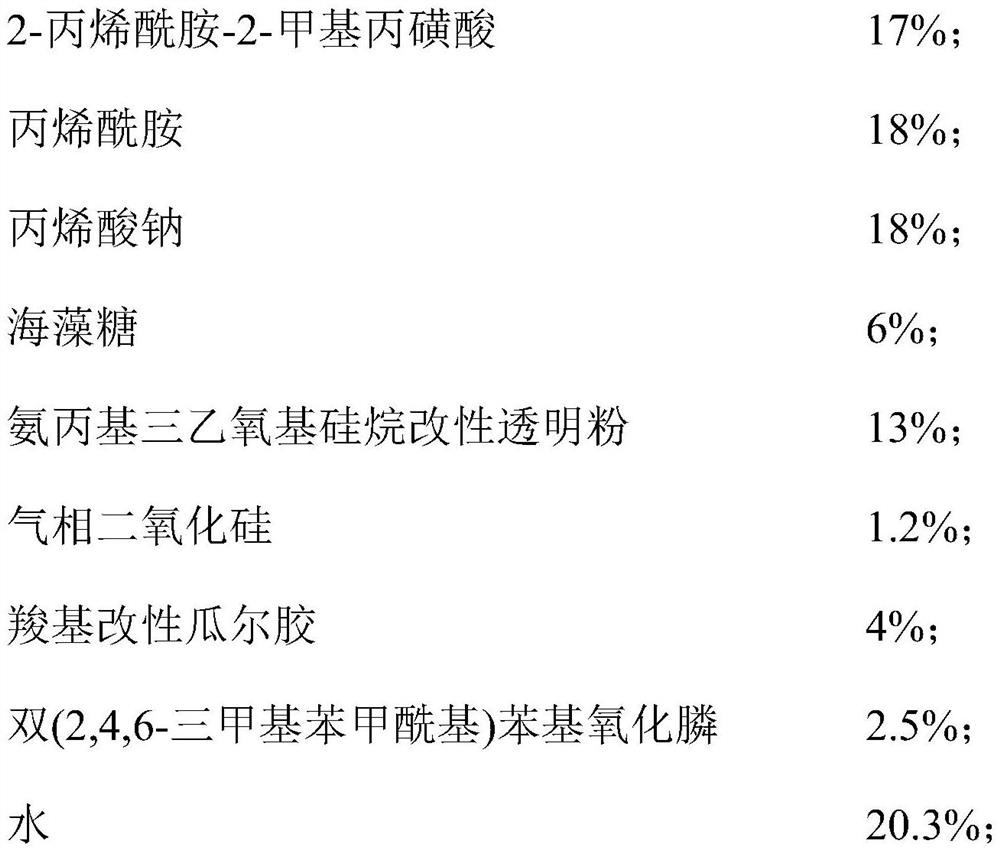

Embodiment 1

[0071]

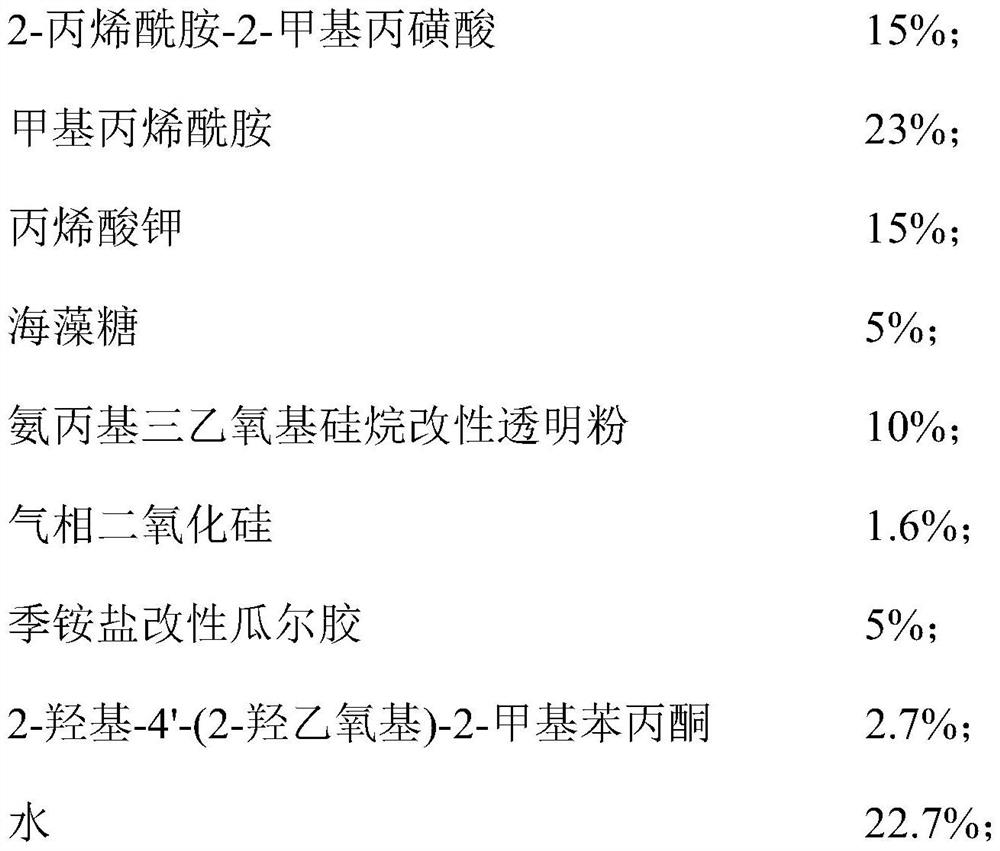

Embodiment 2

[0080]

Embodiment 3

[0089]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a screw hole protective adhesive, a preparation method and application thereof. The screw hole protective glue includes the following components in mass percentage: 15-20% of 2-acrylamide-2-methylpropanesulfonic acid, 16-23% of amide monomer, 15-20% of acrylate, trehalose 5-8%, transparent powder 10-20%, fumed silica 0.5-2% and initiator 2-3%. The preparation method comprises the following steps: mixing 2-acrylamide-2-methylpropanesulfonic acid, trehalose and water to obtain a mixture A; mixing the mixture A, fumed silica and transparent powder to obtain a mixture B; and then Mixing the mixture B, amide monomer and acrylate to obtain a mixture C; mixing the mixture C with an initiator to obtain the screw hole protective glue. The screw hole protective adhesive provided by the invention is high temperature resistant, odorless, non-toxic, environmentally safe and can meet the processing requirements for surface treatment of structural parts of precision electronic products.

Description

A kind of thread hole protective glue and its preparation method and application technical field The invention belongs to adhesive technical field, be specifically related to a kind of threaded hole protective glue and preparation method and application thereof. Background technique [0002] With the development of society, many industries need to temporarily bond or protect materials under the limitation of process conditions. For example, when a certain process needs to position the material or damage the material, UV glue can be used for the material The material is bonded or protected, and the UV glue is taken out after the process is completed, and then the next process is carried out. Due to the differences in various processes, the There are also various requirements for colloids for bonding or protection. [0003] For example, the structural components of electronic products such as notebook computers, power banks, mobile hard disks, etc. are often made of hard ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J4/02C09J4/06C09J11/04C09J11/06C09J11/08

CPCC09J4/06C09J11/04C09J11/06C09J11/08

Inventor 贾录阳刘翘楚何峰

Owner 上海仁速新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com