Self-fusion anti-corrosion adhesive tape and preparation method of self-fusion adhesive thereof

An adhesive layer and tape technology, applied in the direction of adhesive, film/sheet adhesive, etc., to achieve the effect of convenient construction, good chemical resistance, safe and environmentally friendly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

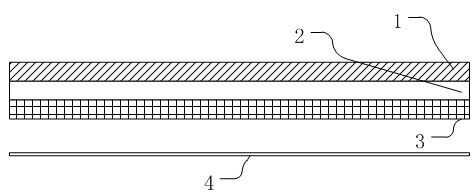

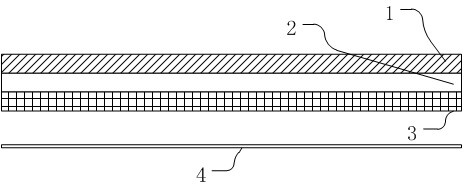

Image

Examples

Embodiment 1

[0022] Example 1 : Proportion by mass fraction (%) butyl rubber (1751) 14 parts, polyethylene (7042) 5 parts, EPDM rubber (4045) 10 parts, low molecular weight polyisobutylene (PB1400) 18 parts, naphthenic oil 4.5 parts, 25 parts of calcium carbonate, 0.5 parts of antioxidant (1010) and 23 parts of C5 petroleum resin.

[0023] Accurately weigh the raw materials prepared from the fusion adhesive according to the proportions of the above components. Add butyl rubber and EPDM rubber to a kneader and crush them, add polyethylene, knead and melt at 145±10°C; add low molecular weight polyisobutylene and naphthenic oil, and knead for 0.5 hours; then add calcium carbonate, anti Oxygen and C 5 Petroleum resin, kneaded for 1 hour. The prepared glue is made into a tape through a glue applicator, and cut according to requirements.

[0024] The measured peel strength of the tape at 23±2°C is 20.5N / cm, the peeling state is cohesive failure, the shear strength at 23±2°C is 0.056MPa, and...

Embodiment 2

[0025] Example 2 : According to mass fraction (%), 22 parts of butyl rubber (1751), 10 parts of polyethylene (7042), 7.5 parts of low molecular weight polyisobutylene (PB1400), 30 parts of calcium carbonate, 8 parts of carbon black, antioxidant ( 1010) 0.5 parts and C5 petroleum resin 22 parts.

[0026] Accurately weigh the raw materials prepared from the fusion adhesive according to the proportions of the above components. Add butyl rubber to a kneader and crush it, add polyethylene, knead and melt at 145±10°C; add low molecular weight polyisobutylene and knead for 0.5 hours; then add calcium carbonate, carbon black, antioxidant and C 5 Petroleum resin, kneaded for 1 hour. The prepared glue is made into a tape through a glue applicator, and cut according to requirements.

[0027] The measured peel strength of the tape at 23±2°C is 42.6N / cm, the peeling state is cohesive failure, the shear strength at 23±2°C is 0.076MPa, and the peel strength at 50±2°C is 4.7N / cm, cohesive...

Embodiment 3

[0028] Example 3 : According to mass fraction (%), 45 parts of butyl rubber (1751), 8.5 parts of polyethylene (7042), 13 parts of naphthenic oil, 16 parts of calcium carbonate, 0.5 parts of antioxidant (1010) and terpene resin ( TR-100) 17 parts.

[0029] Accurately weigh the raw materials prepared from the fusion adhesive according to the proportions of the above components. Add butyl rubber to a kneader and crush it, add polyethylene, knead and melt at 145±10°C; add naphthenic oil and knead for 0.5 hours; then add calcium carbonate, antioxidant and terpene resin, knead for 1 hour . The prepared glue is made into a tape through a glue applicator, and cut according to requirements.

[0030] The measured peel strength of the tape at 23±2°C is 49.0N / cm, the peeling state is cohesive failure, the shear strength at 23±2°C is 0.088MPa, and the peel strength at 50±2°C is 6.7N / cm, cohesive failure, shear The shear strength is 0.059MPa.

[0031] It can be seen from the above des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com