New material for reducing LED junction temperature and preparation method thereof

A new type of material and plastic technology, applied in the field of composite materials or parts, can solve the problems of limited use of high-power LED lamp housing materials, poor mechanical strength, complex processing, etc., to improve the ability to transfer and dissipate heat, and improve mechanical strength and processability, improving the effect of compatible links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

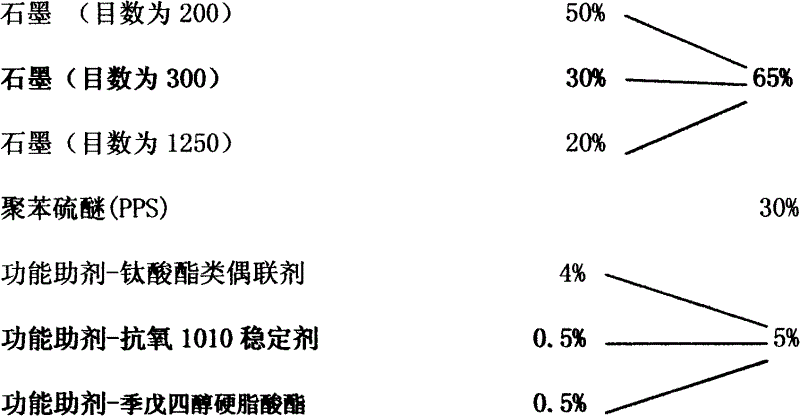

[0058]

[0059] First put the graphite in the above formula in a blast drying oven at 125 degrees to bake for 2 hours, put the polyphenylene sulfide in a blast drying oven at 120 degrees and bake for 2 hours, and then put the weighed raw materials in the internal mixer After turning on the temperature for banburying for 5 minutes, enter the twin-screw extruder for mixing and modification, extrude into strips through the porous die of the machine head, and finally start the hot cutting to pelletize to obtain granular "new materials".

Embodiment 2

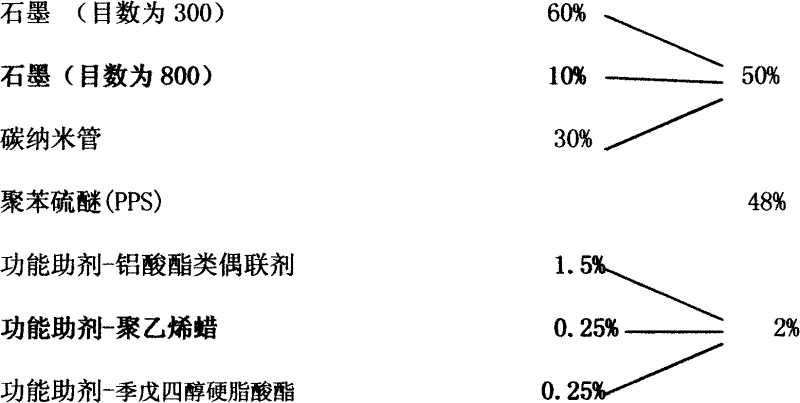

[0061]

[0062] First put the graphite and carbon nanotubes in the above formula in a blast drying oven at 125 degrees to bake for 2 hours, put the polyphenylene sulfide in a blast drying oven at 120 degrees and bake for 2 hours, then graphite and carbon nanotubes, polyphenylene sulfide After the ether and functional additives are mixed separately, the mixture of polyphenylene sulfide and functional additives is firstly metered into the screw extruder for plasticization, and then the mixture of graphite and carbon nanotubes is metered into the screw extruder for further plasticization Evenly dispersed, extruded into strips by the porous die of the machine head, and finally started to cut into pellets to obtain granular "new materials".

Embodiment 3

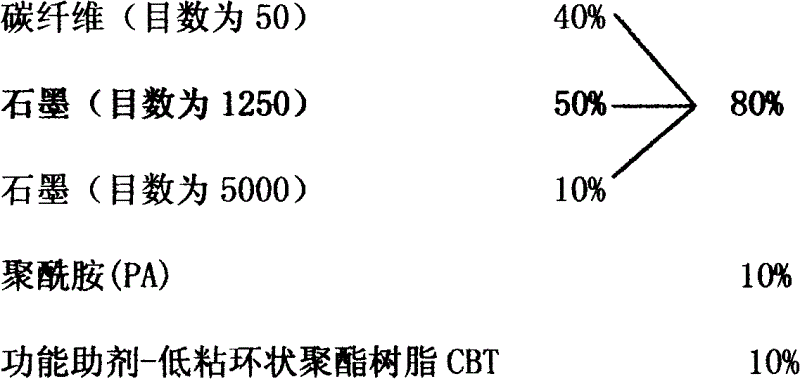

[0064]

[0065] First put the graphite and carbon fiber in the above formula in a blast drying oven at 90 degrees to bake for 8 hours, put the polyamide in a blast drying oven at 105 degrees and bake for 8 hours, and then put the weighed raw materials in the internal mixer Turn on the temperature for 18 minutes and enter the twin-screw extruder. The carbon fiber is added to the side feeder of the twin-screw extruder for mixing and modification. It is extruded into strips by the porous die of the machine head, and finally the hot cutting is started for pelletizing. A granular "new material" is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com