Heat-reflecting heat-insulation inorganic composite material as well preparation method and application thereof

An inorganic composite material and heat reflection technology, which is applied in the direction of reflection/signal coatings, radiation-absorbing coatings, textiles, and papermaking, can solve problems such as unstable chemical properties, complicated preparation processes, and large environmental pollution, and achieve heat reflection insulation. Stable thermal performance, simple and easy preparation process, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

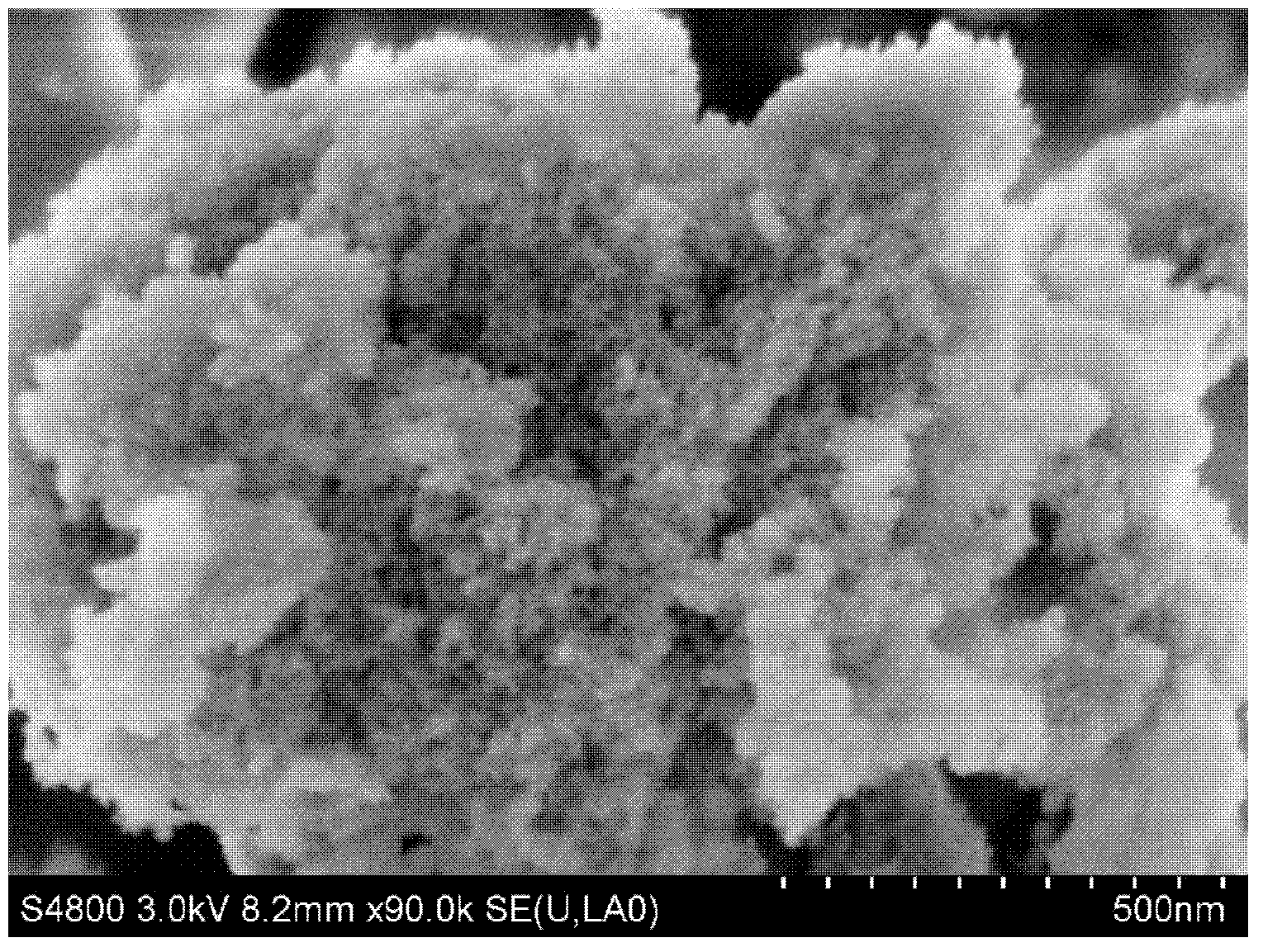

[0050] The preparation method of the heat-reflecting heat-insulating inorganic material given in this embodiment, the specific steps are as follows:

[0051] a) Weigh 4.2202g (11.25mmol) aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 0.5428g (1.25mmol) cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), the inorganic salt of aluminum (Al(NO 3 ) 3 9H 2 O) and inorganic salts of doping elements (Ce(NO 3 ) 3 ·6H 2 O) the mol ratio is 9: 1;

[0052] b) Add 100mL double distilled water to make the concentration of the mixed salt solution 0.125mol / L;

[0053] c) stirring at room temperature for 1 hour to obtain a colorless and transparent solution;

[0054] d) adding dropwise an aqueous sodium hydroxide solution with a concentration of 1 mol / L to the solution while stirring to adjust the pH=7 to 8;

[0055] e) Stirring was continued for 5 hours at room temperature to obtain a milky white emulsion;

[0056] f) filtering and washing, and drying the obtained milky white filter cake at 100° ...

Embodiment 2

[0065] The preparation method of this embodiment is the same as that described in Example 1, except that 4.4546g (11.875mmol) of aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 0.2714g (0.625mmol) cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), the inorganic salt of aluminum (Al(NO 3 ) 3 9H 2 O) and inorganic salts of doping elements (Ce(NO 3 ) 3 ·6H 2 O) in a molar ratio of 19:1.

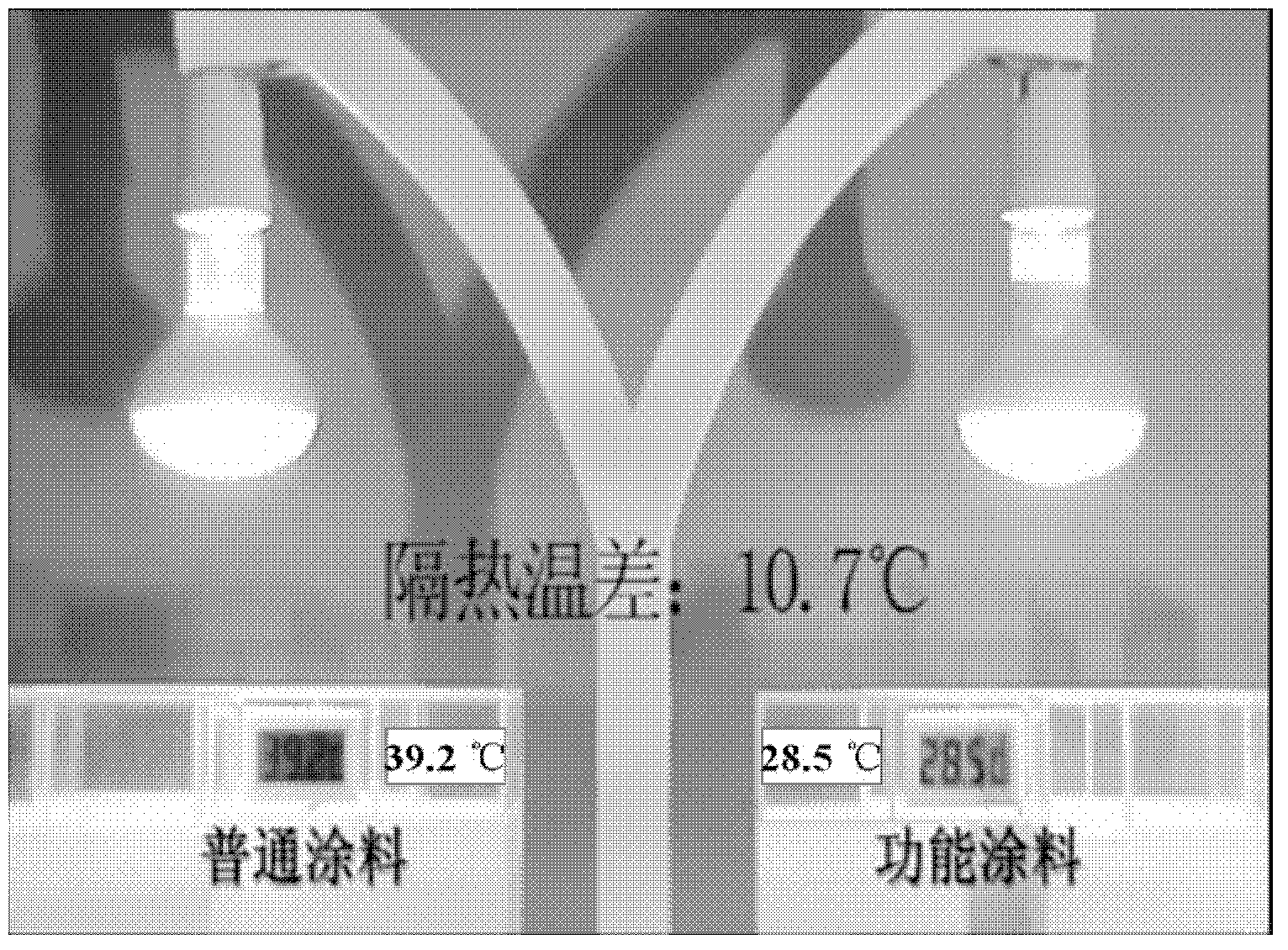

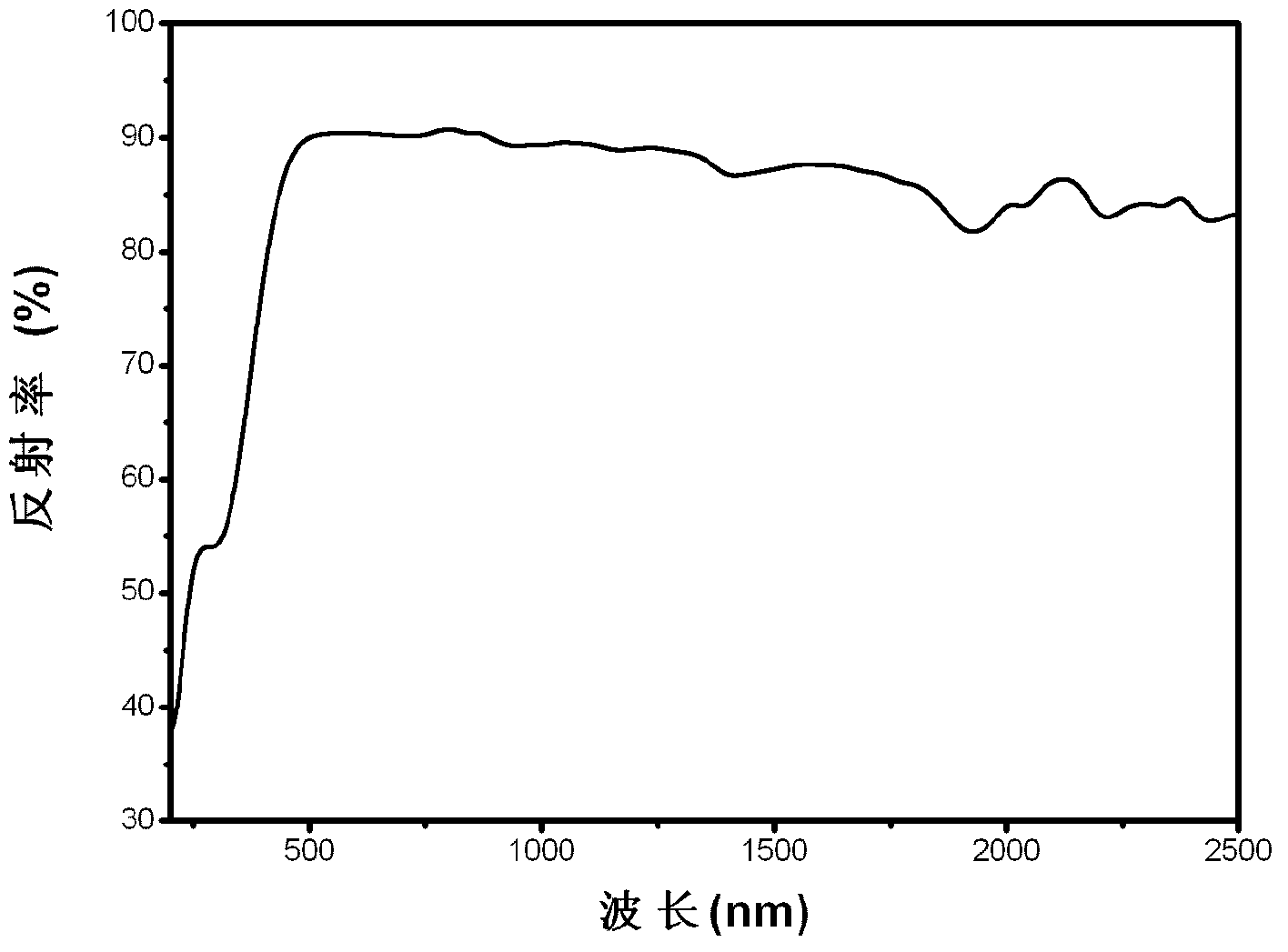

[0066] The ultraviolet-visible-near-infrared reflection spectrum, heat insulation effect diagram, and scanning electron microscope photo analysis results of the heat-reflecting and heat-insulating inorganic material prepared in this example are all the same as those described in Example 1.

Embodiment 3

[0068] The preparation method of this embodiment is the same as that described in Example 1, except that in step a), 3.7513g (10mmol) of aluminum nitrate (A1(NO 3 ) 3 .9H 2 O) and 1.0855g (2.5mmol) cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), the inorganic salt of aluminum (Al(NO 3 ) 3 9H 2 O) and inorganic salts of doping elements (Ce(NO 3 ) 3 ·6H 2 O) in a molar ratio of 4:1.

[0069] The ultraviolet-visible-near-infrared reflection spectrum, heat insulation effect diagram, and scanning electron microscope photo analysis results of the heat-reflecting and heat-insulating inorganic material prepared in this example are all the same as those described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com