Preparation method of high-purity nano-powder Mg2-xSiTMx thermoelectric materials

A nano-powder and thermoelectric material technology, applied in the direction of nanotechnology, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of reducing the ZT value of Si thermoelectric materials, long reaction time, low product purity and uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

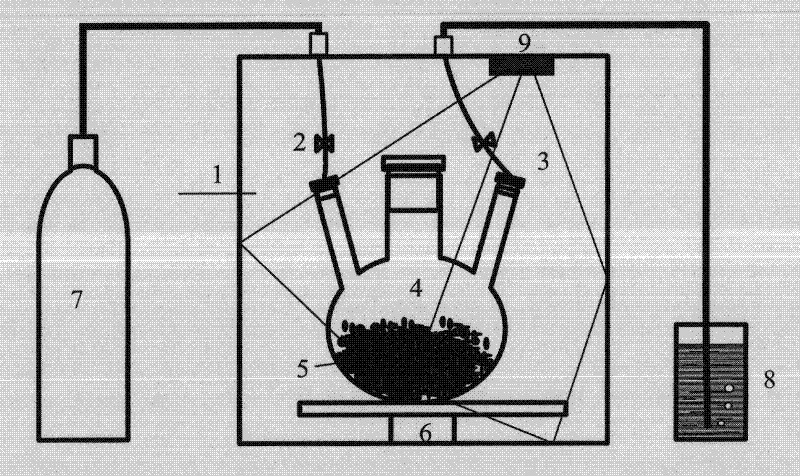

[0014] MgH 2 powder (average particle size 36μm, purity 99.8%), nano-Si powder (average particle size 20nm, purity 99.90%) and YH 2-3 powder (average particle size 35μm, purity 99.8%) with 1.9975mol MgH 2 , 1mol Si and 0.0025mol YH 2 The reaction powder 5 is formed after mixing in proportion, and then the reaction powder 5 is put into a three-necked quartz flask 4, and the mouth of the bottle is sealed. Place the sealed three-necked quartz flask 4 in the microwave oven 1, and connect the two ends with the argon gas bottle 7 and the exhaust pipe inserted into the mineral oil 8 respectively; first open the argon gas inlet valve 2, and then open the exhaust valve at the other end 3. Make continuous air bubbles emerge from the exhaust pipe inserted into the mineral 7, and prevent the air from flowing back into the pipe; start the microwave power supply, and react the powder 5 under the microwave power of 0.5kW for 5 minutes, then turn off the power supply to make the reaction G...

Embodiment approach 2

[0016] MgH 2 powder (average particle size 36μm, purity 99.8%), nano-Si powder (average particle size 20nm, purity 99.90%) and YH 2-3 powder (average particle size 35μm, purity 99.8%) with 1.995mol MgH 2 , 1mol Si and 0.005mol YH 2 The reaction powder 5 is formed after mixing in proportion, and then the reaction powder 5 is put into a three-necked quartz flask 4, and the mouth of the bottle is sealed. Place the sealed three-necked quartz flask 4 in the microwave oven 1, and connect the two ends with the argon gas bottle 7 and the exhaust pipe inserted into the mineral oil 8 respectively; first open the argon gas inlet valve 2, and then open the exhaust valve at the other end 3. Make the exhaust pipe inserted into the mineral 7 have continuous bubbles, and prevent the air from flowing back into the pipe; start the microwave power supply, and the reaction powder 5 reacts under the microwave power of 1kW for 3 minutes, and then turn off the power supply to make the reaction gen...

Embodiment approach 3

[0018] (average particle size 36μm, purity 99.8%), nano Si powder (average particle size 20nm, purity 99.90%) and YH 2-3 powder (average particle size 35μm, purity 99.8%) with 1.99mol MgH 2 , 1mol Si and 0.01mol YH 2 The reaction powder 5 is formed after mixing in proportion, and then the reaction powder 5 is put into a three-necked quartz flask 4, and the mouth of the bottle is sealed. Place the sealed three-necked quartz flask 4 in the microwave oven 1, and connect the two ends with the argon gas bottle 7 and the exhaust pipe inserted into the mineral oil 8 respectively; first open the argon gas inlet valve 2, and then open the exhaust valve at the other end 3. Make the exhaust pipe inserted into the mineral 7 have continuous bubbles, and prevent the air from flowing back into the pipe; start the microwave power supply, and the reaction powder 5 reacts under the microwave power of 1kW for 3 minutes, and then turn off the power supply to make the reaction generate Mg 2-x S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com