Method for preparing titanium diboride ceramic with titanium aluminum carbon as sintering aid

A sintering aid, titanium diboride technology, applied in the field of boride ceramics, can solve the problem of difficult sintering of titanium diboride ceramics, and achieve the effects of easy control of process conditions, excellent mechanical properties, and low densification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The raw material is TiB with a particle size of 2500 mesh 2 Powder 28.5 grams, 2000 mesh 3 AlC 2 1.5 grams of powder were ball-milled in an alcoholic medium for 20 hours, cold-pressed into a cake shape under a pressure of 10 MPa, and the cold-pressing time was 8 minutes. In the middle, the heating rate was raised to 1400° C. at a rate of 5° C. / min for 2 hours, and the hot pressing pressure was 40 MPa. A material composed of two phases of titanium boride and titanium carbide is obtained, titanium carbide accounts for about 4.5wt.%, the rest is titanium boride, titanium carbide is evenly distributed in the titanium boride matrix, and the density of the material is about 93 %.

Embodiment 2

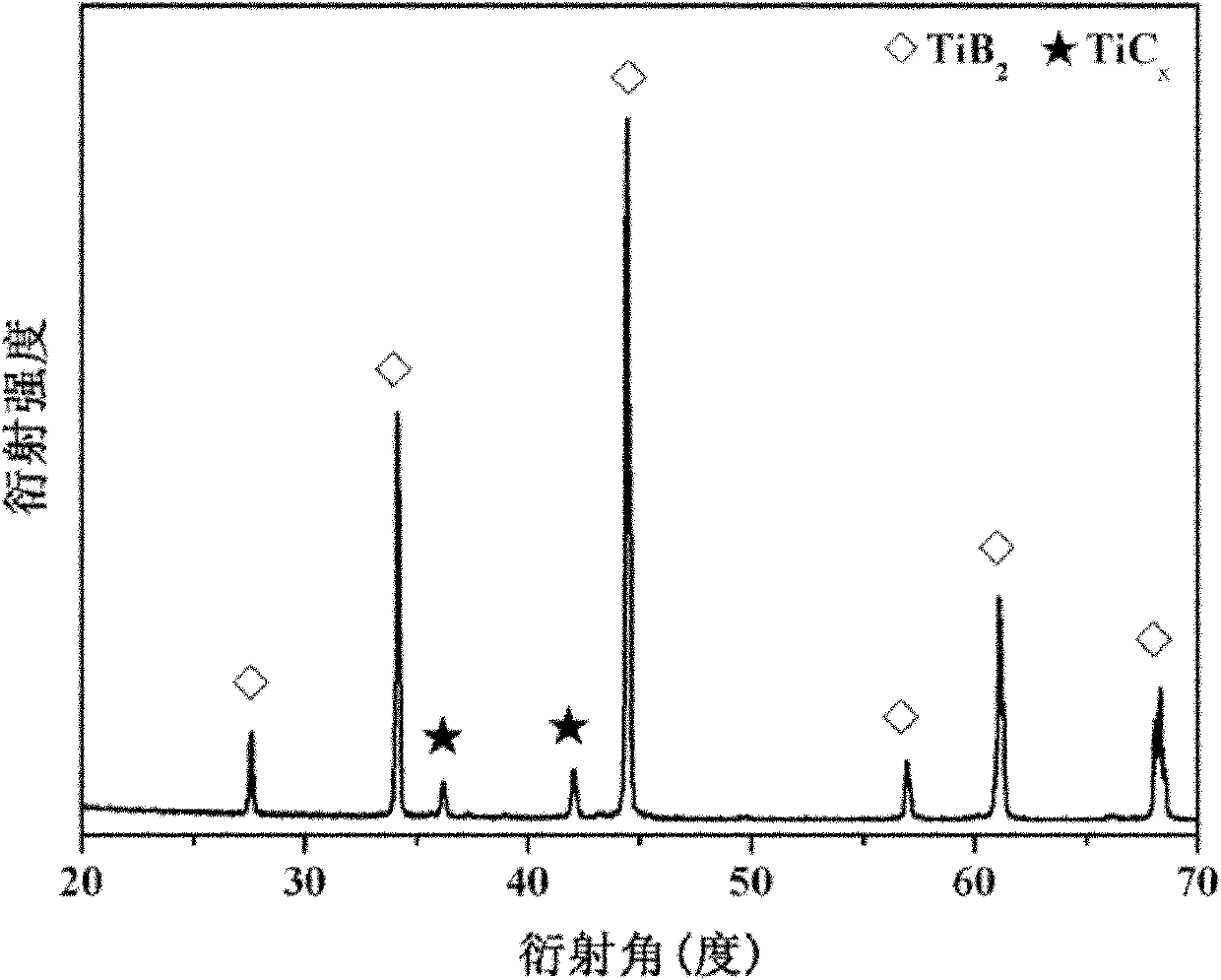

[0026] The raw material is TiB with a particle size of 5000 mesh 2 Powder 90.0g, 800 mesh 3 AlC 2 10 grams of powder were ball-milled in an alcoholic medium for 12 hours, cold-pressed into a cake shape under a pressure of 5 MPa, and the cold-pressing time was 6 minutes. 15 °C / min heating rate to 1500 °C in situ reaction hot pressing for 1 hour, the hot pressing pressure is 30 MPa. Obtain a material composed of two phases of titanium boride and titanium carbide, titanium carbide accounts for about 9wt.%, the rest is titanium boride, titanium carbide is evenly distributed in the titanium boride matrix, and the density of the material is about 99% , the bending strength is 710.9±36.5MPa, the fracture toughness is 4.8±0.2MPa m 1 / 2 , the hardness is 25.1±0.7GPa, and the elastic modulus is 567GPa. The corresponding X-ray diffraction spectrum, the scanning electron microscope photo after corrosion and the morphology of the fracture are listed in figure 1 and Figure 2(a)-Figure...

Embodiment 3

[0028] The raw material is TiB with particle size of 1000 mesh 2 Powder 40 grams, 3000 mesh 3 AlC 2 10 grams of powder were ball-milled in an alcoholic medium for 30 hours, cold-pressed into a cake shape under a pressure of 20 MPa, and the cold-pressing time was 1 minute. In the process, the heating rate was raised to 1600° C. in situ for 1 hour at a heating rate of 10 / min, and the hot pressing pressure was 20 MPa. Obtain a material composed of titanium boride, titanium carbide and a small amount of titanium aluminum carbon three phases, titanium carbide accounts for 14wt.%, titanium aluminum carbon accounts for 3wt.%, the rest is titanium boride, titanium carbide and titanium aluminum carbon are evenly distributed In a titanium boride matrix, the material is about 99% dense.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com