Method for producing potassium bicarbonate through self-carbonization multiple-effect cross flow continues evaporation crystallization

A technology of potassium bicarbonate and evaporation crystallization, which is applied in the fields of chemical industry, resources and environment, and can solve problems such as steam consumption that cannot be solved well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

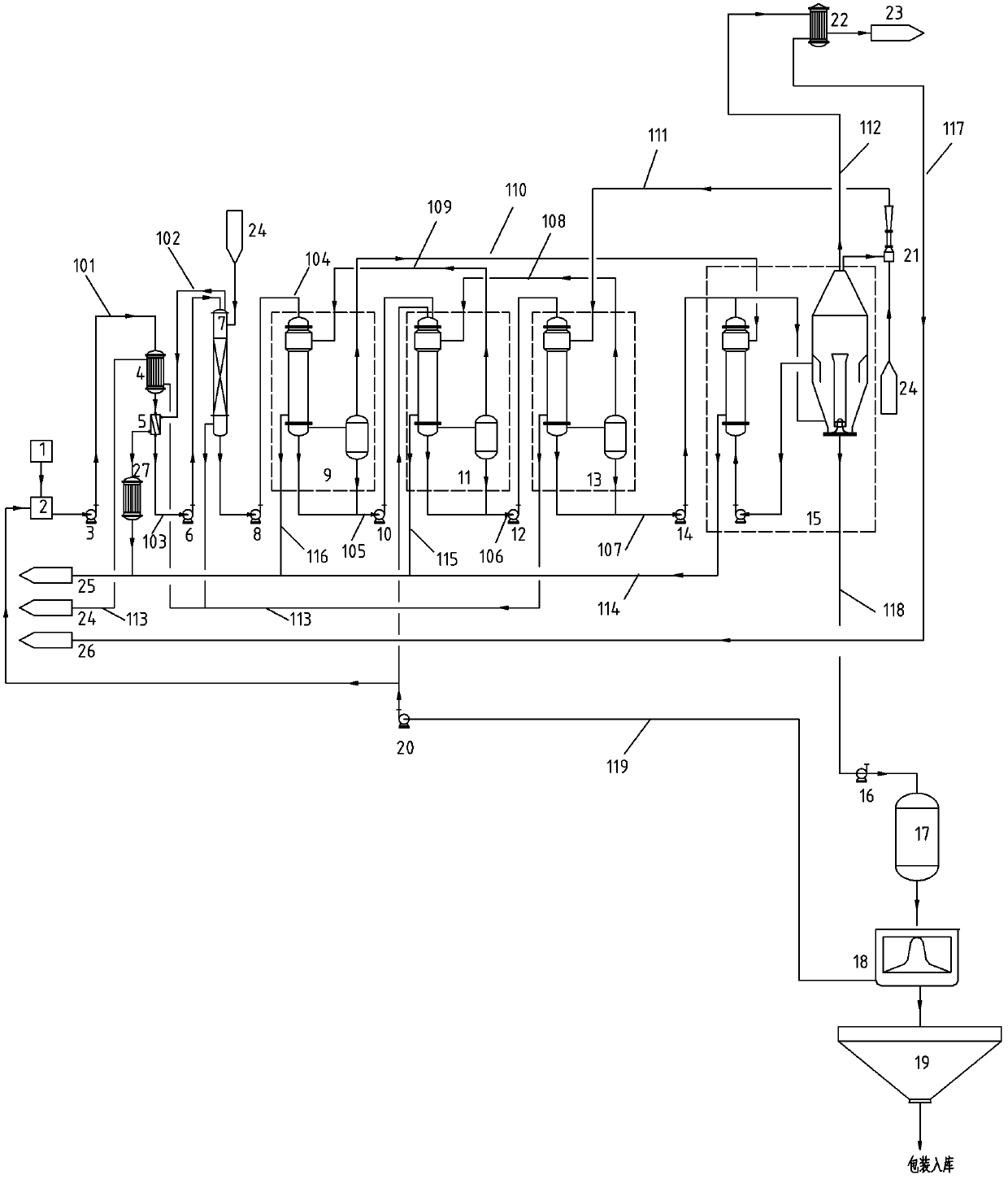

Image

Examples

Embodiment 1

[0066] Embodiment 1, a kind of self-carbonization multi-effect cross-flow continuous evaporation crystallization produces the method for potassium bicarbonate, carries out following steps successively:

[0067] 1. Set potassium bicarbonate ion exchange solution containing ammonium bicarbonate in liquid storage tank I1, the concentration of ammonium bicarbonate is 50g / L, the concentration of potassium bicarbonate is 230g / L; the rest is water.

[0068] The potassium bicarbonate mother liquor that contains potassium carbonate is set in liquid storage tank II2; The concentration of potassium carbonate is 120g / L, and the concentration of potassium bicarbonate is 420g / L; All the other are water.

[0069] After the above-mentioned potassium bicarbonate ion-exchange solution and potassium bicarbonate mother liquor are mixed according to the volume flow ratio of 5: 2, the mixed feed liquid is obtained; the mixed feed liquid contains ammonium bicarbonate 30g / L, contains potassium carbona...

Embodiment 2

[0090] Embodiment 2, a kind of method (working flow is the same as embodiment 1) that self-carbonization multi-effect cross-flow continuous evaporation crystallization produces potassium bicarbonate:

[0091] 1. Set potassium bicarbonate ion exchange solution containing ammonium bicarbonate in liquid storage tank I1, the concentration of ammonium bicarbonate is 50g / L, the concentration of potassium bicarbonate is 230g / L; the rest is water.

[0092] The potassium bicarbonate mother liquor that contains potassium carbonate is set in liquid storage tank II2; The concentration of potassium carbonate is 120g / L, and the concentration of potassium bicarbonate is 420g / L; All the other are water.

[0093] After the above-mentioned potassium bicarbonate ion-exchange solution and potassium bicarbonate mother liquor are mixed according to the volume flow ratio of 5: 2, the mixed feed liquid is obtained; the mixed feed liquid contains ammonium bicarbonate 30g / L, contains potassium carbonate...

Embodiment 3

[0113] Embodiment 3: a kind of method (working flow is the same as embodiment 1) that produces potassium bicarbonate from carbonization multi-effect cross-flow continuous evaporation crystallization:

[0114] 1. Set potassium bicarbonate ion exchange solution containing ammonium bicarbonate in liquid storage tank I1, the concentration of ammonium bicarbonate is 50g / L, the concentration of potassium bicarbonate is 230g / L; the rest is water.

[0115] The potassium bicarbonate mother liquor that contains potassium carbonate is set in liquid storage tank II2; The concentration of potassium carbonate is 120g / L, and the concentration of potassium bicarbonate is 420g / L; All the other are water.

[0116] After the above-mentioned potassium bicarbonate ion-exchange solution and potassium bicarbonate mother liquor are mixed according to the volume flow ratio of 5: 2, the mixed feed liquid is obtained; the mixed feed liquid contains ammonium bicarbonate 30g / L, contains potassium carbonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com