A kind of double-layer film all-solid-state film lithium battery spray pyrolysis battery manufacturing method

A double-layer thin-film, all-solid-state technology, applied in the direction of electrolyte battery manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of difficult optimization of process conditions, affecting the overall performance of the battery, and the low degree of particle matching, and achieve improved The effect of conductance, stress reduction, and impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

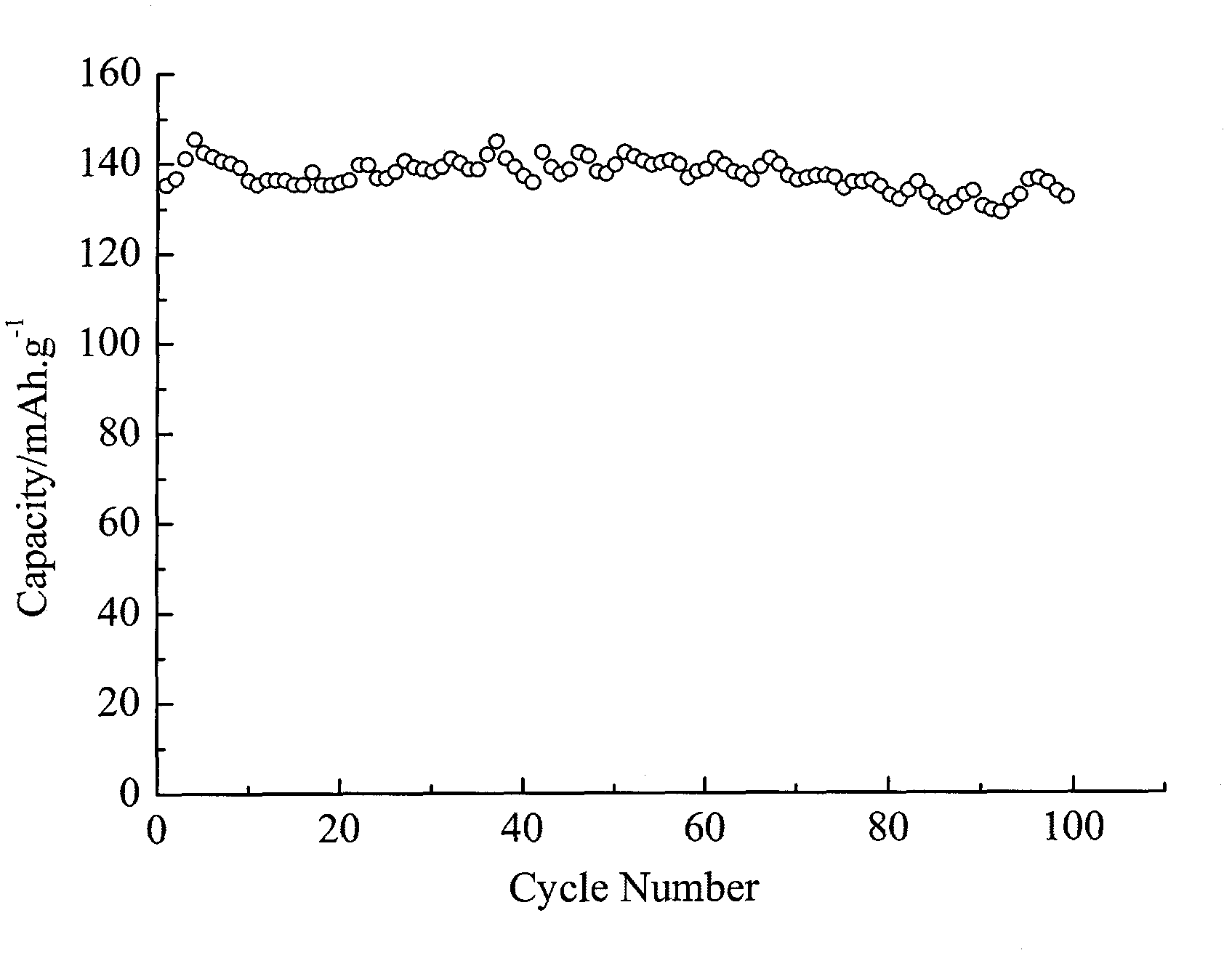

Embodiment 1

[0019] Example 1: Place the copper substrate on the surface of a stainless steel heating plate at a constant temperature of 450°C, and connect the spray gun A to the precursor solution I: ammonium metavanadate NH 4 VO 3 (0.3mol / L), ammonium chloride NH 4 Cl(0.08mol / L), lithium acetate Li(CH 3 COO) (0.3mol / L), lanthanum nitrate La(NO 3 ) 3 (0.2mol / L), n-butyl titanate Ti(OC 4 h 9 ) 4 (0.4mol / L), CH acetate 3 COOH (0.2mol / L), and ethylene glycol methyl ether (0.1wt%) aqueous solution. Gun B is connected to Precursor Solution II: Lithium Acetate Li(CH 3 COO) (0.4mol / L), n-butyl titanate Ti(OC 4 h 9 ) 4 (0.5mol / L), CH acetate 3Aqueous solution of COOH (0.3mol / L) and ethylene glycol methyl ether (0.15wt%). Spray gun A is 10 cm vertically away from the working surface, and the angle of intersection with the working surface is 65°. The carrier gas atomizes and sprays precursor solution I with a flow rate of 5 mL / min at a pressure of 100 KPa for 30 minutes to the substrat...

Embodiment 2

[0020] Example 2: Place the copper substrate on the surface of a stainless steel heating plate at a constant temperature of 300°C, and connect the spray gun A to the precursor solution I: ammonium metavanadate NH 4 VO 3 (0.4mol / L), ammonium chloride NH 4 Cl(0.09mol / L), lithium acetate Li(CH 3 COO) (0.51mol / L), lanthanum nitrate La(NO 3 ) 3 (0.4mol / L), n-butyl titanate Ti(OC 4 h 9 ) 4 (0.8mol / L), CH acetate 3 COOH (0.2mol / L), and n-pentanol (0.5wt%) aqueous solution. Gun B is connected to Precursor Solution II: Lithium Acetate Li(CH 3 COO) (0.3mol / L), n-butyl titanate Ti(OC 4 h 9 ) 4 (0.375mol / L), acetic acid CH 3 Aqueous solution of COOH (0.2mol / L) and ethylene glycol methyl ether (0.2wt%). Spray gun A is 12 cm vertically away from the working surface, and the angle of intersection with the working surface is 70°. The carrier gas atomizes and sprays the precursor solution I with a flow rate of 6 mL / min at a pressure of 80 KPa for 40 minutes to the substrate. Then...

Embodiment 3

[0021] Example 3: Place the nickel sheet substrate on the surface of a stainless steel heating plate at a constant temperature of 500°C, and connect the spray gun A to the precursor solution I: ammonium metavanadate NH 4 VO 3 (0.45mol / L), ammonium chloride NH 4 Cl(0.1mol / L), lithium acetate Li(CH 3 COO) (0.95mol / L), lanthanum nitrate La(NO 3 ) 3 (0.8mol / L), n-butyl titanate Ti(OC 4 h 9 ) 4 (1.6mol / L), CH acetate 3 COOH (0.3mol / L), and polyvinyl alcohol (0.7wt%) aqueous solution. Gun B is connected to Precursor Solution II: Lithium Acetate Li(CH 3 COO)(0.2mol / L), n-butyl titanate Ti(OC 4 h 9 ) 4 (0.25mol / L), CH acetate 3 Aqueous solution of COOH (0.3mol / L) and ethylene glycol methyl ether (0.2wt%). Spray gun A is 15 cm away from the working surface vertically, and the angle of intersection with the working surface is 80°. The carrier gas atomizes and sprays the precursor solution I with a flow rate of 10 mL / min at a pressure of 150 KPa for 80 minutes to the substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com