Surface-modified inorganic matrix and method for preparation thereof

A matrix, inorganic technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of negative impact of phosphorus environment, limitation, sensitivity to nucleophilic attack, etc., to achieve a high degree of functionalization, improve stability, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] Example 1: Modified unsupported TiO according to the invention 2 Film layer preparation

[0149] As commonly used to prepare TiO with a pore size of 3 to 5 nm 2 As in the top layer of the membrane, unsupported TiO was produced by preparing a sol 2 film layer. Recipes for such preparations are known in the art and can be found, for example, in the following publications T. Van Gestel, C; Vandecasteele, A. Buekenhoudt, C. Dotremont, J. Luyten, R. Leysen, B. Van der Bruggen, G. Maes, J. Membr. Sci, 207, 2002, pp. 73-89. Specifically, for this example, titanium tetraisopropoxide (Ti(OC 3 h 7 ) 4 ) (TTI, supplied by Acros Organics) to prepare the sol. Use HNO 3 Peptization of the sol is obtained. Then, as in the preparation of real TiO 2 In the case of the mesoporous membrane top layer the same amount of additional solvent and binder was added. However, instead of dip-coating the porous membrane support with the sol-containing diluted binder as is done in membrane...

Embodiment 2

[0152] Example 2: Powdered unsupported TiO modified according to the invention 2 Characterization of the film layer

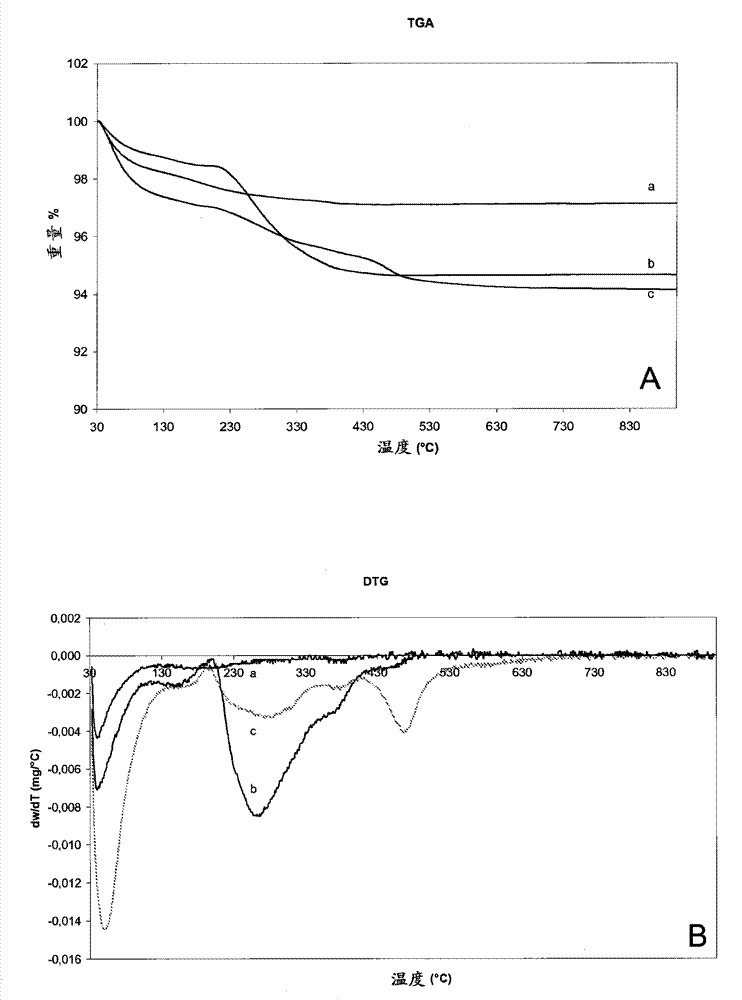

[0153] Untreated TiO was prepared as described in Example 1 2 Powder, BuOH pretreated TiO 2 powder, and C1-modified TiO after BuOH pretreatment 2 powder. figure 1 A shows untreated TiO 2 Powder, BuOH pretreated TiO 2 C1 modified TiO after powder and BuOH pretreatment 2 Thermogravimetric analysis (TGA) of the powder, figure 1 B shows the corresponding differential temperature gradient (DTG). These results show weight loss over different temperature intervals. Alcohol pretreatment resulted in weight loss from 230 °C to 430 °C due to the formation of weak Ti-O-C bonds. After modification with methylorganomagnesium compounds, a weight loss above 430 °C was measured due to metal-carbon covalent bonding (at M 1 -C in the case of Ti-C).

[0154] Untreated TiO was prepared as described in Example 1 2 Powder and BuOH pretreated TiO 2 powder. In a similar m...

Embodiment 3

[0157] Example 3: Powdered unsupported TiO modified according to the invention using different solvents 2 Film layer preparation and characterization

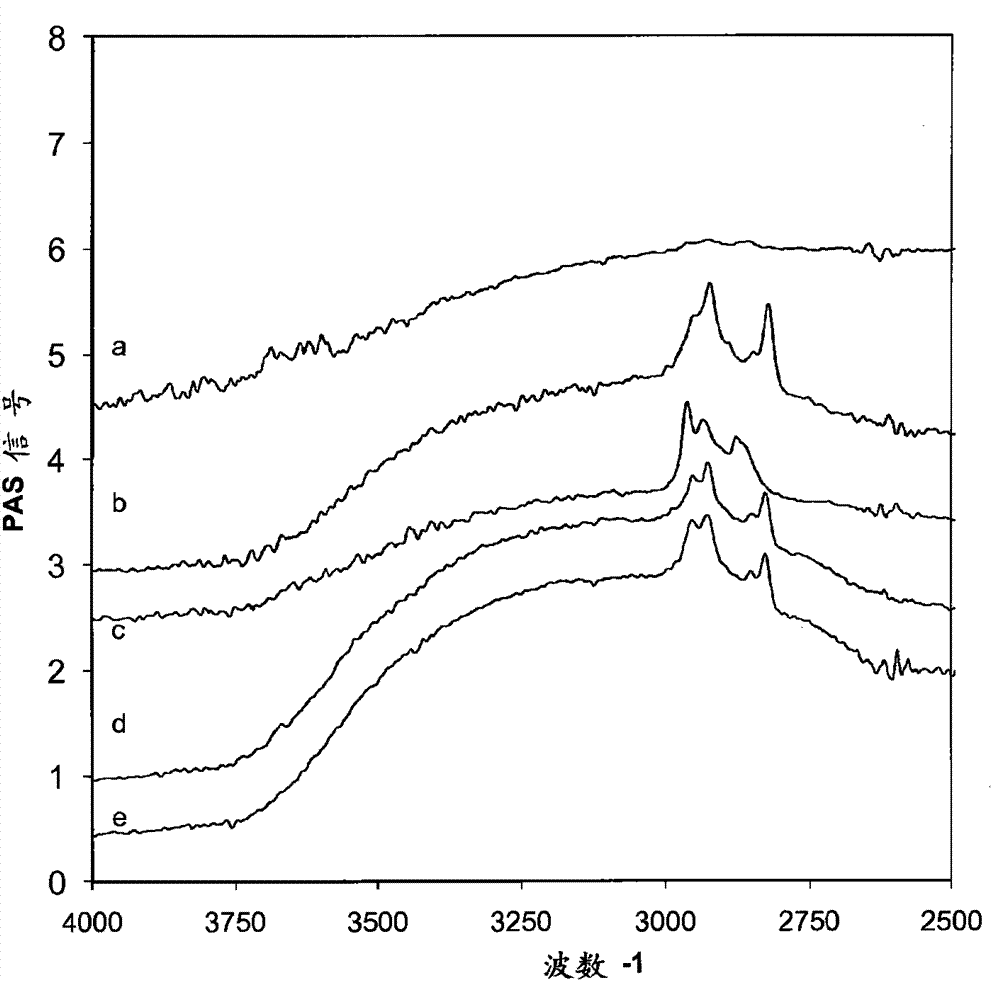

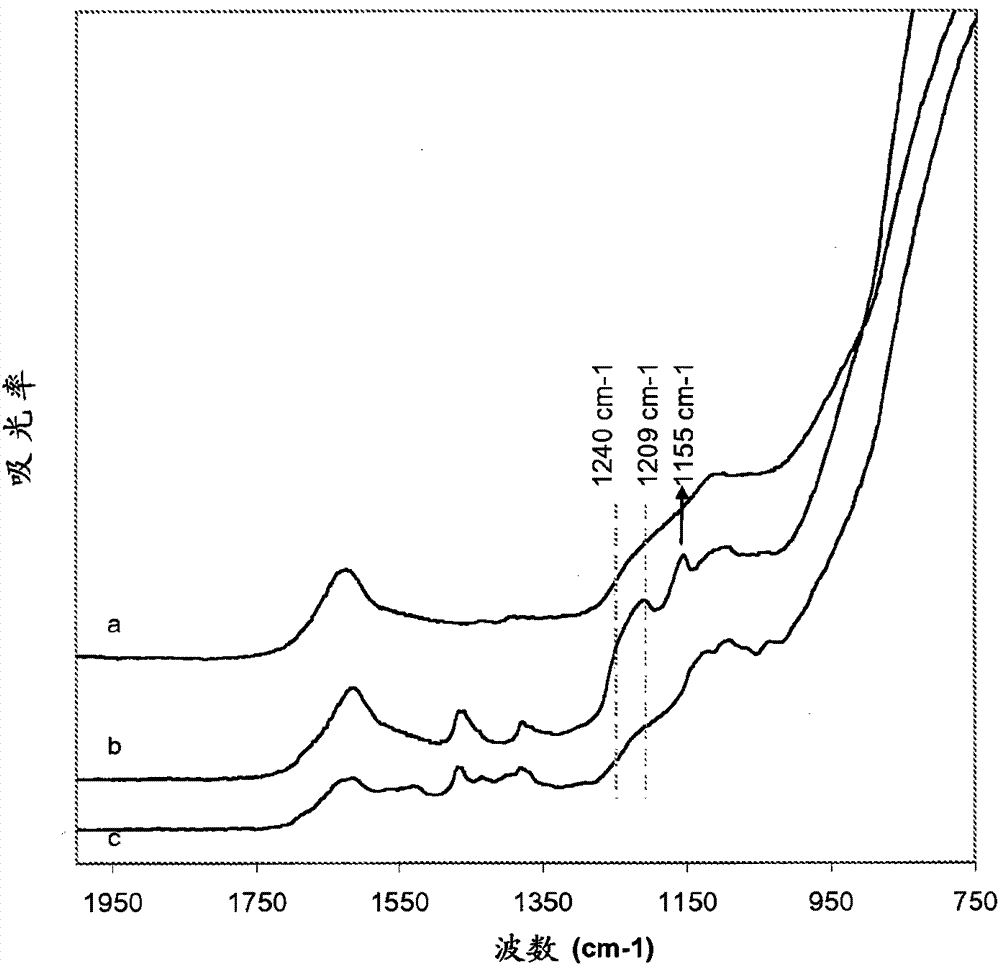

[0158] In this example, powdered unsupported TiO 2 The film layer material is modified, the difference is that different solvents are used for the reaction with the alkyl organic magnesium bromide in step d. The reaction was carried out in diethyl ether (DEE), tetrahydrofuran (THF) and cyclopentyl methyl ether (CPME) by the method described. MeOH was used as the alcohol for pretreatment, and octylorganomagnesium bromide was used as the organomagnesium compound. These modified unsupported TiO 2 The TGA results of the films showed weight loss above 430 °C, indicating the formation of M in all solvents 1 -C covalent bond. The PAS-IR spectra of these materials are in Figure 4 The stretching vibrations of the C–H bonds of the octyl functional groups of all powders are given and shown in .

[0159] Also the modified TiO 2 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com