Detection method for special fire retardant content in textile

A detection method and flame retardant technology, which are applied in the detection field of flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1. Optimization and selection of parameters when gas chromatography-mass spectrometer measures

[0060] In order to obtain suitable gas chromatography-mass spectrometry parameters, screen and optimize instrument parameters:

[0061] Instruments used: GC-MS 2010plus gas chromatography-mass spectrometry (SHIMAZU, Japan), equipped with AOC20i+s autosampler, Rxi-5MS quartz capillary column, 30 m × 0.25 mm (i.d.) × 0.25 mm, or equivalent;

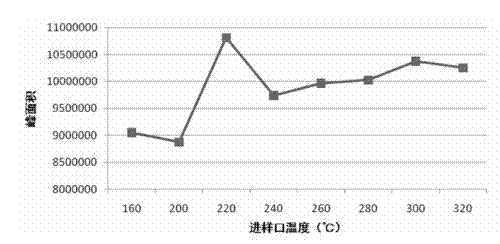

[0062] (1) Optimization of the inlet temperature

[0063] Select different inlet temperatures, and observe the change of the chromatographic peak area of each target compound (see figure 1 ), the results showed that for TEPA, as the inlet temperature increased, the chromatographic peak area of the TEPA target compound reached the highest point at 220 °C, and then the peak area decreased slightly and tended to be flat. Therefore, the inlet temperature selected in the present invention is 220°C.

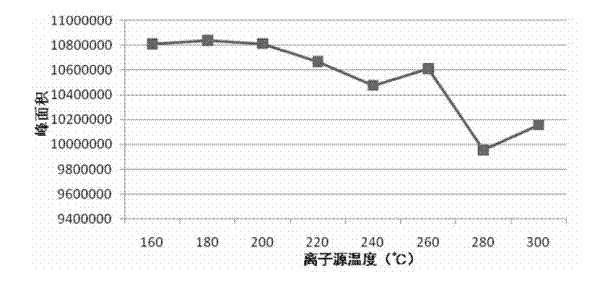

[0064] (2) Optimizat...

Embodiment 2

[0077] Example 2: The detection method of tri-[aziridine]-phosphine oxide content in textiles comprises the following steps:

[0078] (1) Sample preparation

[0079] Take 5.0 ~ 10.0 g of cotton fabric sample, cut it to less than 0.5 cm × 0.5 cm, and mix well;

[0080] (2) Sample extraction

[0081] Weigh 1.00 g of the above-mentioned cotton fabric sample and place it in a 5 mL extraction tank, extract it with a fast solvent extraction apparatus, the extraction agent is a mixture of n-hexane and acetone, the volume ratio of the two is 7:3, and the extraction temperature is 60 °C , the pressure was 10.34 MPa, static extraction was performed for 5 min, and each sample was extracted 3 times cyclically. After each extraction, it was washed with 60% of the extraction solvent of the extraction cell volume, and finally purged with nitrogen, and the extraction solution was collected in a 60 mL belt. Transfer the collected extraction solution to a 125 mL chicken heart bottle in a co...

Embodiment 3

[0111] Example 3: Establishment of linear relationship in the detection of tris-[aziridine]-phosphine oxide content in textiles:

[0112] Using the method in Example 2, use the TEPA standard solution diluted with blank matrix solution for GC-MS analysis, the prepared concentrations are: 1 mg / L, 4 mg / L, 10 mg / L, 20 mg / L, 30 mg / L, the determination results were analyzed by the workstation software, the determination linear range was 1-100 mg / L, and the detection limit LOD was 1 mg / L. Take cotton fabric as an example, get the standard curve spectrogram see Figure 7 , the abscissa in the figure indicates concentration (mg / L), and the ordinate indicates (peak area). For actual samples, the lower limit of determination LOQ is less than 4 mg / L. Under the experimental conditions determined by this method, the linear equations and correlation coefficients of other matrices are shown in Table 4 (where Y is the peak area; X is the concentration of TEPA, mg / L). The results showed th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com