Preparation method of organic silicon microcapsule powder waterproof agent

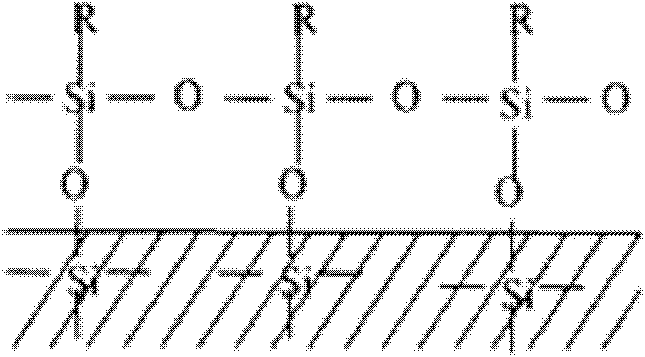

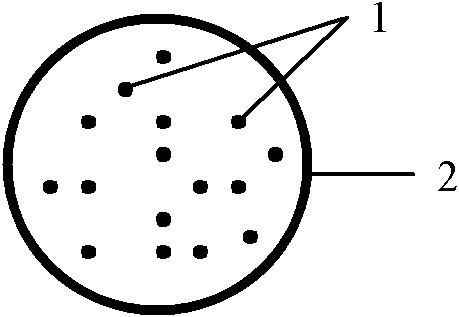

An organosilicon and water repellent technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of condensation reaction, stabilization difficulties, poor stability of liquid water repellants, etc., to improve water resistance and hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

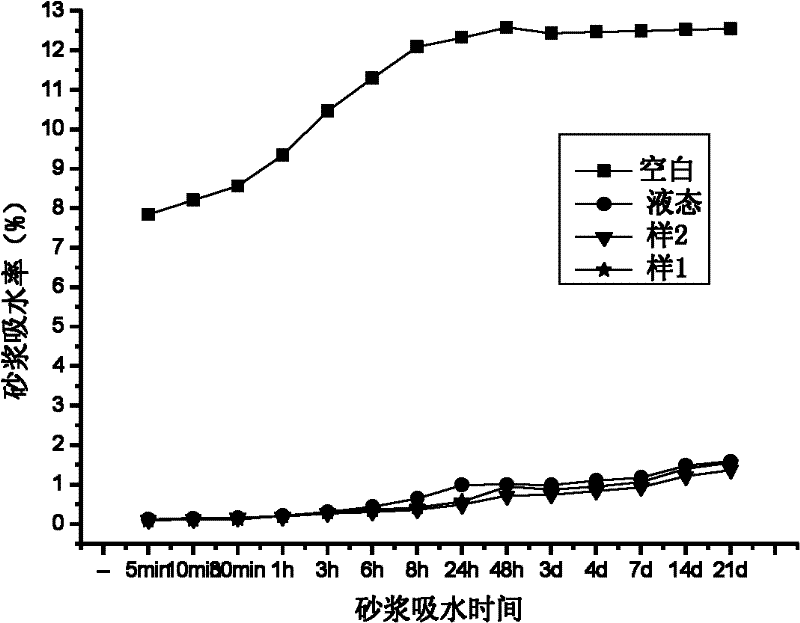

Examples

Embodiment 1

[0048] (1) Add solid polyvinyl alcohol into water at room temperature while stirring, and heat the water to about 70°C for about 30 minutes to dissolve, then cool to room temperature with a concentration of 2%;

[0049] (2) Select nano-calcium carbonate as the inorganic mineral filler; compound polydimethylsiloxane and isobutyltriethoxysilane at a mass ratio of 3:97 to form a complex high-efficiency silicone waterproofing agent occupying silicone microparticles. 63% of the total mass of the capsule powder; add nano-calcium carbonate, which accounts for 15% of the total mass of the high-efficiency silicone waterproofing agent, to the composite waterproofing agent, and then put it in an ultrasonic disperser for 15 minutes to make a uniform dispersion;

[0050] (3) The polyvinyl alcohol aqueous solution prepared by step (1) is added in the dispersion of (4), so that the polyvinyl alcohol polymer accounts for 28% of the total mass of the organosilicon microcapsule powder, and place...

Embodiment 2

[0057] (1) Add solid polyvinyl alcohol into water at room temperature while stirring, and heat the water to about 70°C for about 30 minutes to dissolve, then cool to room temperature with a concentration of 8%;

[0058] (2) Nano-metakaolin is selected as the mineral filler; polydimethylsiloxane and octyltriethoxysilane are compounded into a complex high-efficiency silicone water repellent at a mass ratio of 50:50. In this embodiment, organic The specific dosage of the silicon water repellent accounts for 66.7% of the total mass of the silicone microcapsule powder water repellent; then weigh the nano-metakaolin which accounts for 18% of the total mass of the high-efficiency water repellent, add it to the water repellant, and then put it into an ultrasonic disperser for 30 minutes to prepare into a uniform dispersion;

[0059] (3) the polyvinyl alcohol aqueous solution prepared by step (1) is added in the dispersion system of (2), so that the polyvinyl alcohol polymer accounts f...

Embodiment 3

[0065] (1) Add solid polyvinyl alcohol into water at room temperature while stirring, and heat the water to about 70°C for about 30 minutes to dissolve, then cool to room temperature with a concentration of 20%;

[0066] (2) select nano-silica as the inorganic mineral filler; select butyltriethoxysilane as an efficient organosilicon waterproofing agent, and the specific consumption of the organosilicon waterproofing agent accounts for 1 / 3 of the total mass of the organosilicon microcapsule powder waterproofing agent in the present embodiment 54%; Add nano-silica, which accounts for 8% of the total mass of high-efficiency silicone water repellent, into the water repellent, and then put it into an ultrasonic disperser for 15 minutes to make a uniform dispersion;

[0067] (3) Add the polyvinyl alcohol aqueous solution prepared by step (1) into the dispersion of (2) again, so that the polyvinyl alcohol polymer accounts for 42% of the total mass of the organic silicon microcapsule p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com