Ceramic electrode material and process for producing the ceramic electrode material

A technology of ceramic electrodes and manufacturing methods, which can be applied to ceramic products, cable/conductor manufacturing, electrodes, etc., and can solve problems such as remaining problems in processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

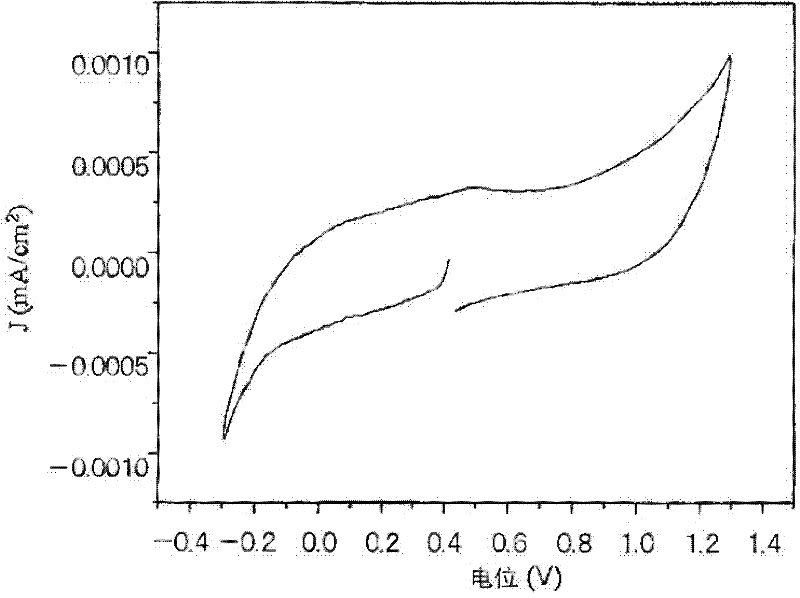

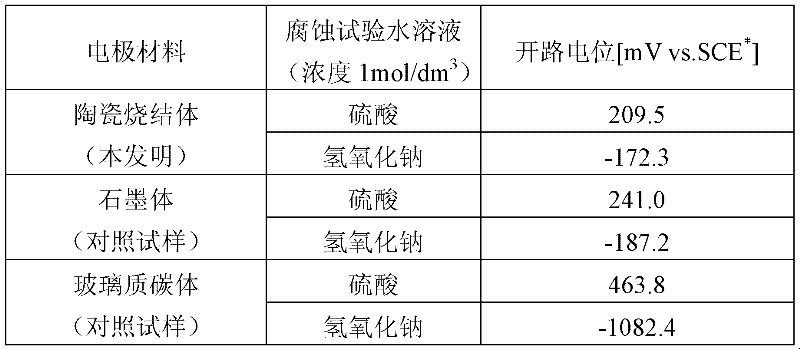

Image

Examples

Embodiment 1

[0071] First, alumina powder (Sinterable alumina manufactured by Showa Denko Co., Ltd., AL-160SG-4, average particle size: 0.6 μm) as a ceramic raw material, methacrylamide as a polymerizable substance, and N, N'-methylene bisacrylamide as a dispersant, ammonium polycarboxylate dispersant (CELUNAD305, manufactured by Chukyo Oil & Fat Co., Ltd.) and distilled water as a dispersant. Blending was carried out to prepare a water slurry composition. In addition, the preparation of the composition was carried out as follows: First, methacrylamide and N,N'-methylenebisacrylamide were dissolved in distilled water, then polycarboxylate ammonium-based dispersant was added, and then After the alumina powder was prepared, it was mixed for 25 hours in a constant temperature water tank set at 25° C. using a wet ball mill.

[0072] [Table 1]

[0073] Slurry composition table (combined amount relative to 100g of slurry)

[0074]

Dispersant...

experiment example

[0080] After adding 1.03 mg of a polymerization initiator and 0.17 mg of a polymerization catalyst to 100 g of the above composition, an appropriate amount of the composition to which the above polymerization initiator was added was supplied to a disc-shaped (diameter 5 cm x thickness 1 cm) molding die . The methacrylamide and N,N'-methylenebisacrylamide contained in the composition were polymerized by leaving these molding dies in a room (temperature: 25° C.) for 3.0 hours, and then by removing them from the molding dies, mold to obtain a disc-shaped molded body.

[0081] The obtained molded article was placed in a room of a constant humidity dryer, and dried for 3 days until the relative humidity in the room was lowered from 90% RH to 60% RH at a rate of 10% RH per day. After the drying, the dried molded body was reduced and fired at a temperature of 1700° C. for 2 hours while introducing argon gas using a small electric furnace set in an argon atmosphere to obtain a cerami...

Embodiment 2

[0094] First, alumina powder (Sinterable alumina manufactured by Showa Denko Co., Ltd., AL-160SG-4, average particle size: 0.6 μm) as a ceramic raw material, methacrylamide as a polymerizable substance, and N, N'-methylenebisacrylamide as a permanent monomer, ammonium polycarboxylate dispersant (CELUNAD305, manufactured by Chukyo Oil & Fat Co., Ltd.) as a dispersant, and distilled water. Blending was carried out to prepare a water slurry composition. In addition, the preparation of the composition was carried out as follows: First, methacrylamide and N,N'-methylenebisacrylamide were dissolved in distilled water, then polycarboxylate ammonium-based dispersant was added, and then After adding the alumina powder, the mixture was mixed for 25 hours in a constant temperature water tank set at 25° C. using a wet ball mill.

[0095] [Table 4]

[0096] Slurry composition table (combined amount relative to 100g of slurry)

[0097]

Alumina powder

distilled water

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com