Method for manufacturing laser chip for natural gas detection

A manufacturing method, natural gas technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of high technological content, high price, and inapplicability of natural gas detection in lasers, so as to improve single-mode yield, improve efficiency, The effect of reducing line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

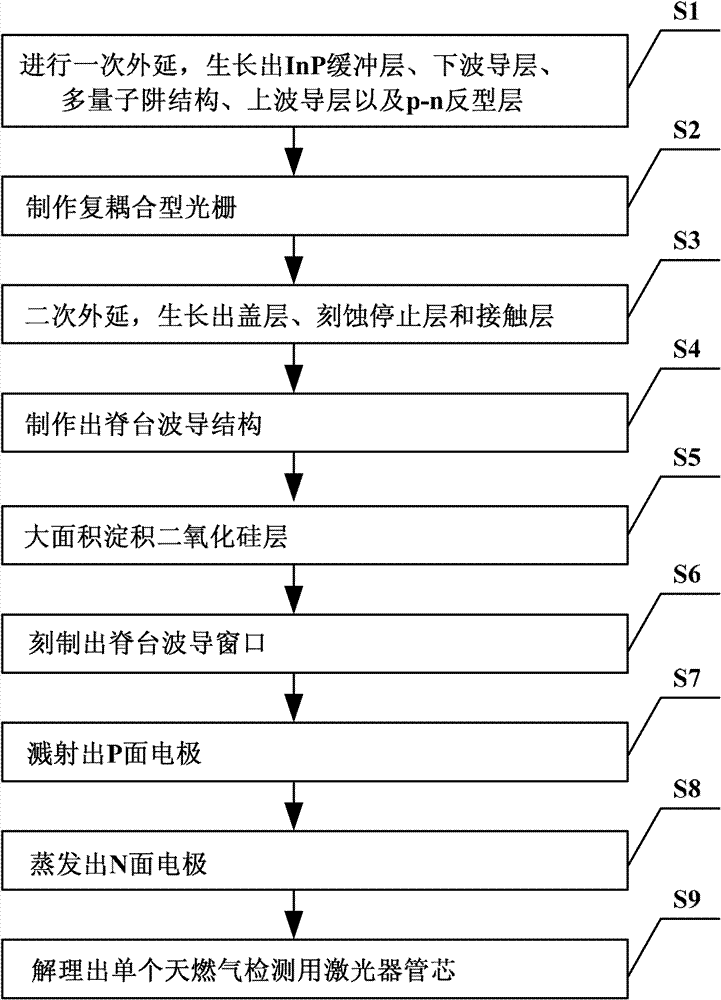

[0045] The manufacturing method of the laser chip for natural gas detection provided by the present invention, such as figure 1 shown, including:

[0046] Step S1:

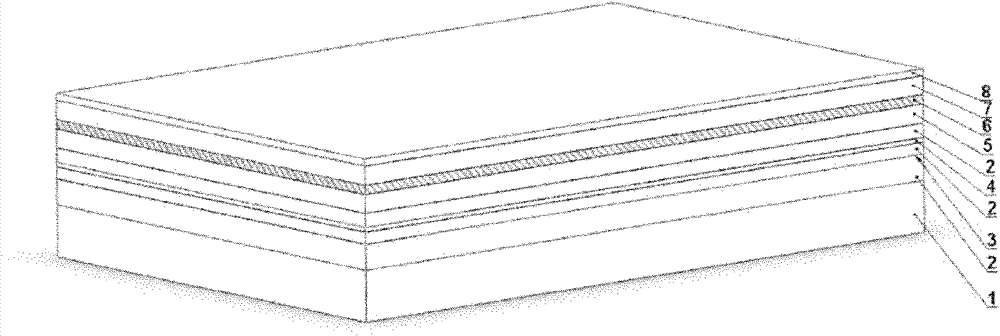

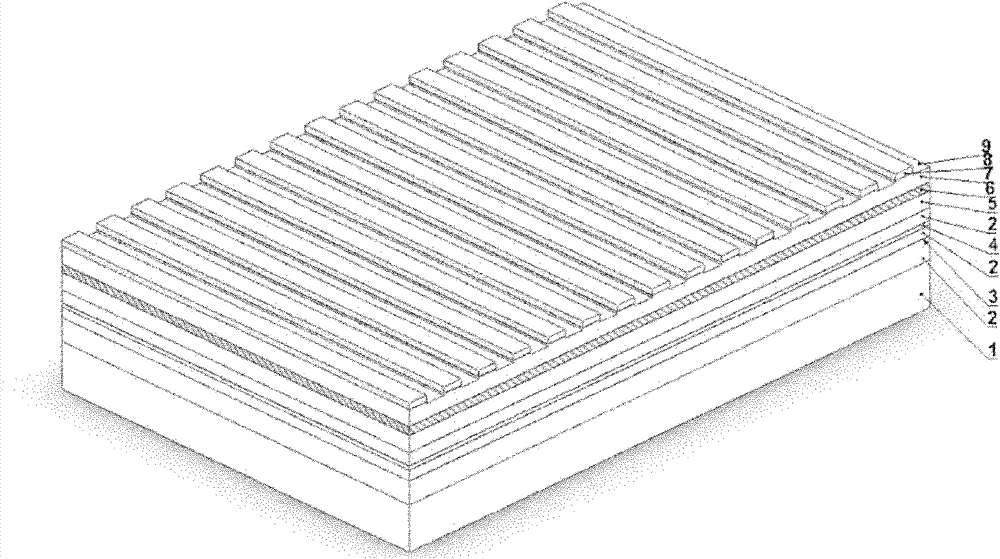

[0047] Such as figure 2 As shown, an epitaxy was performed on an n-InP (n-type indium phosphide) substrate 1 by low-pressure metal-organic chemical vapor deposition. The method has low cost and is suitable for large-scale production; the grown thickness is 1 μm, and the doping concentration is 2×10 18 InP buffer layer 2, InGaAsP (Indium Gallium Arsenide Phosphorus) lower waveguide layer 5 with a thickness of 100nm, InGaAs (Indium Gallium Arsenide) / InGaAsP multi-quantum well structure 6, InGaAsP upper waveguide layer 7 with a thickness of 100nm and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com