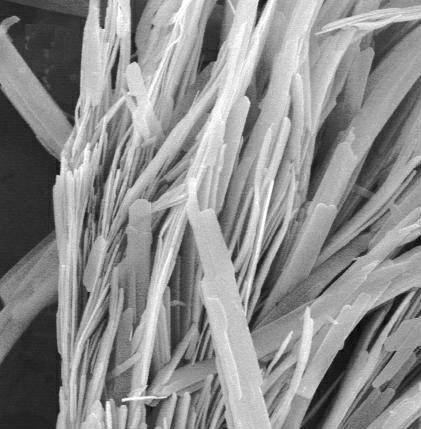

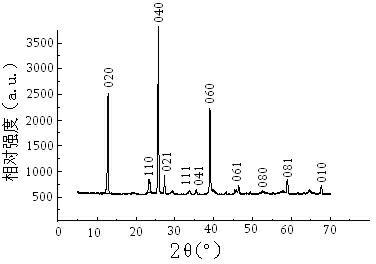

Method for preparing molybdenum trioxide material with orthorhombic phase single crystal nano belt structure

A technology of single crystal nanometer and molybdenum trioxide, which is applied in the field of inorganic non-metallic nanomaterials and nanometers, which can solve the problems of safety and difficult control of acidification operation, expensive preparation equipment, high reaction temperature, etc., and achieve easy control of process and simple preparation equipment , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dissolve ammonium heptamolybdate in deionized water after grinding to obtain a concentration of 20g / 100ml ammonium heptamolybdate solution and age for 2 days, then add the same volume of deionized water; acidify the above solution with nitric acid while stirring, The concentration of nitric acid is 3mol / L, and the addition is 1 time of the ammonium heptamolybdate solution, and the stirring is continued for 30min to obtain a transparent molybdic acid sol; the ethanol solution of template agent CTAB is added to the molybdic acid sol, and the CTAB concentration is 2mol / L, The amount added is 0.1 times the volume of the sol, and stirred vigorously for 1 hour;

[0032]Move the molybdic acid sol containing the template agent into a polytetrafluoroethylene-lined stainless steel reactor, conduct a hydrothermal reaction at 120°C for 36 hours, cool to room temperature, and obtain a hydrothermal product; filter the obtained hydrothermal reaction product, first Wash with absolute e...

Embodiment 2

[0035] Dissolve ammonium heptamolybdate in deionized water after grinding to obtain a concentration range of 50g / 100ml ammonium heptamolybdate solution and age for 8 days, then add the same volume of deionized water; acidify the above solution with nitric acid while stirring , the concentration of nitric acid is 7mol / L, the addition is 3 times of the ammonium heptamolybdate solution, and the stirring is continued for 90min to obtain a transparent molybdic acid sol; the ethanol solution of template agent CTAB is added to the molybdic acid sol, and the CTAB concentration is 5mol / L , the amount added is 0.5 times the volume of the sol, and vigorously stirred for 5 hours;

[0036] Move the molybdic acid sol containing the template agent into a polytetrafluoroethylene-lined stainless steel reaction kettle, conduct a hydrothermal reaction at 180°C for 12 hours, cool to room temperature, and obtain a hydrothermal product; filter the obtained hydrothermal reaction product, first Wash ...

Embodiment 3

[0038] Dissolve ammonium heptamolybdate in deionized water after grinding to obtain a concentration range of 40g / 100ml ammonium heptamolybdate solution and age for 6 days, then add the same volume of deionized water; acidify the above solution with nitric acid while stirring , the nitric acid concentration is 5mol / L, the addition is 2 times of the ammonium heptamolybdate solution, and the stirring is continued for 60min to obtain a transparent molybdic acid sol; the ethanol solution of the template agent CTAB is added to the molybdic acid sol, and the CTAB concentration is 4mol / L , the amount added is 0.4 times the volume of the sol, and vigorously stirred for 4 hours;

[0039] Move the molybdic acid sol containing the template agent into a polytetrafluoroethylene-lined stainless steel reaction kettle, conduct a hydrothermal reaction at 150°C for 24 hours, cool to room temperature, and obtain a hydrothermal product; filter the obtained hydrothermal reaction product, first Wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com