A kind of synthetic method of ammonium fluoride modified titanium dioxide visible light catalyst

A technology of titanium dioxide and synthesis method, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reducing the hydrophobic stability of hydrophobic materials, the toxic price of silane coupling agents, and no practical application value, etc. Achieve high UV and visible light activity, good hydrophobic stability, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of synthetic method of ammonium fluoride modified titanium dioxide visible light catalyst, comprises the following steps:

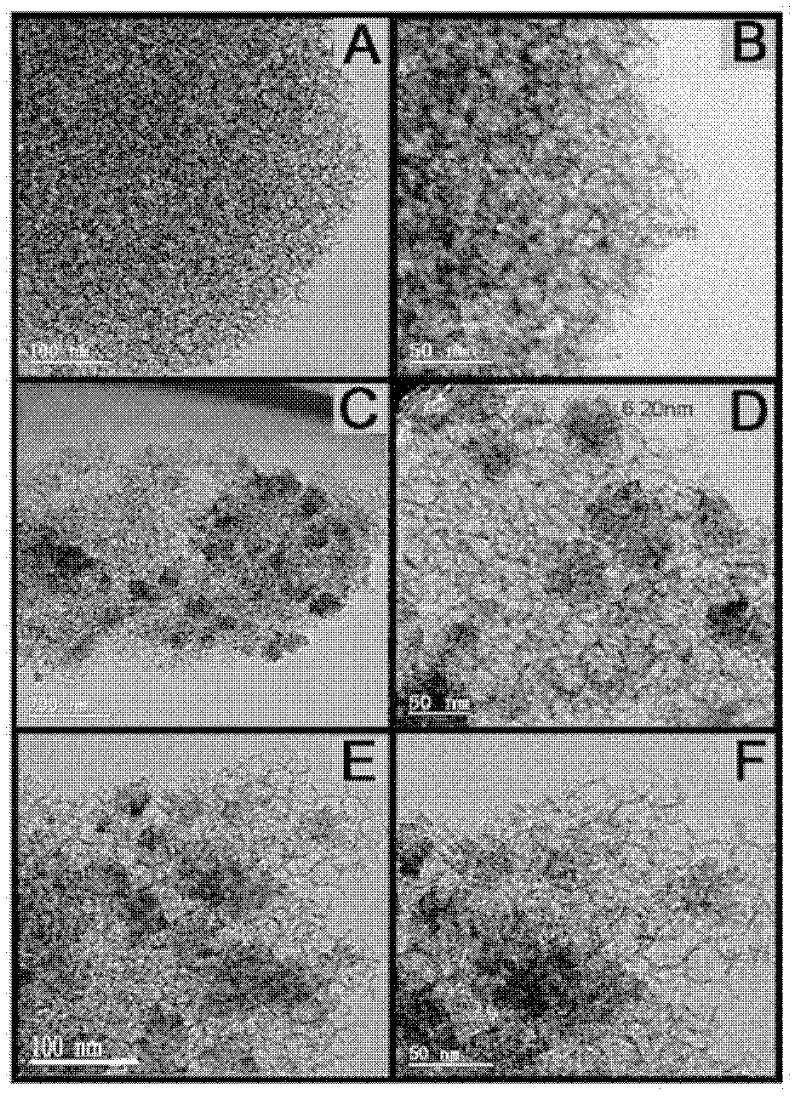

[0037] (1) Preparation of MCF

[0038] Add 8.0g of P123 to 40mL of dilute hydrochloric acid and 260ml of distilled water, stir at 37°C until dissolved. Then add 0.1g NH 4 F and 4.0 g of TMB (1,3,5-trimethylbenzene), mechanically stirred for 1 hour. 18.3ml of TEOS was added dropwise at 37°C, and mechanically stirred for 20 hours. The resulting slurry was hydrothermally heated at 100°C for 24 hours, washed and precipitated, vacuum-dried at 60°C for 12 hours, and then calcined at 550°C for 6 hours to obtain MCF mesoporous Molecular sieve.

[0039] (2) MCF loaded TiO2 2 Catalyst preparation

[0040] Weigh titanium sulfate (Ti(SO 4 ) 2 ) solid 1.2g, added to 25ml twice distilled water, magnetically stirred for 30min, after the titanium sulfate was completely dissolved, then added 0.8g of prepared MCF mesoporous molecular sieve, stirred for...

Embodiment 2

[0051] A kind of synthetic method of ammonium fluoride modified titanium dioxide visible light catalyst, the method comprises the following steps:

[0052] (1) Preparation of foamy mesoporous molecular sieve (mesocellular foam silica, MCF)

[0053] Weigh a certain amount of triblock polymer polyoxyethylene-polyoxypropylene-polyoxyethylene (PEO-PPO-PEO, P123) at 37°C, dissolve in hydrochloric acid solution, the concentration of hydrochloric acid is 1.5mol / L, P123 The concentration in the mixed solution of hydrochloric acid and distilled water is 0.02g / ml, then add NH 4 F and 1,3,5-trimethylbenzene (TMB), P123, NH 4 The weight ratio of F and 1,3,5-trimethylbenzene is 8:0.1:4, stir for 1 hour, add tetraethyl orthosilicate (TEOS), tetraethyl orthosilicate (TEOS) and hydrochloric acid solution at the same temperature The volume ratio is 1:16, stirred for 20 hours, the resulting slurry was transferred to an autoclave, heated in water at 100°C for 24 hours, washed and precipitated,...

Embodiment 3

[0059] A kind of synthetic method of ammonium fluoride modified titanium dioxide visible light catalyst, the method comprises the following steps:

[0060] (1) Preparation of foamy mesoporous molecular sieve (mesocellular foam silica, MCF)

[0061] Weigh a certain amount of triblock polymer polyoxyethylene-polyoxypropylene-polyoxyethylene (PEO-PPO-PEO, P123) at 37°C, dissolve in hydrochloric acid solution, the concentration of hydrochloric acid is 1.8mol / L, three The concentration of the block polymer polyoxyethylene-polyoxypropylene-polyoxyethylene (PEO-PPO-PEO, P123) in the mixed solution of hydrochloric acid and distilled water is 0.03g / ml, and then NH 4 F and 1,3,5-trimethylbenzene (TMB), triblock polymer polyoxyethylene-polyoxypropylene-polyoxyethylene (PEO-PPO-PEO, P123), NH 4 The weight ratio of F and 1,3,5-trimethylbenzene is 8:0.1:4, stir for 1 hour, add tetraethyl orthosilicate (TEOS), tetraethyl orthosilicate (TEOS) and hydrochloric acid solution at the same temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com