Method for synthetizing particle reinforced metal matrix composite material in pulsed electric field

A pulsed electric field and composite material technology is applied in the field of preparation of particle-reinforced metal matrix composite materials to achieve the effects of low production cost, guaranteed material properties, and promotion of particle nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

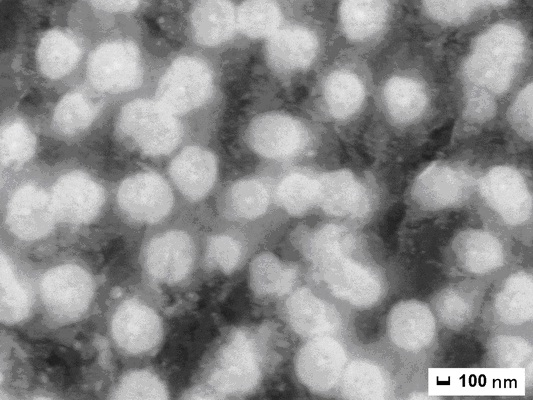

Image

Examples

Embodiment 1

[0029] Raw materials: base metal: aluminum alloy; solid powder: industrial zirconium carbonate (Zr(CO 3 ) 2 ) powder (purity 99.20%), refining degassing agent and slag removal agent;

[0030] In situ reaction equation: 7Al (l) +Zr(CO 3 ) 2(s) =Al 3 Zr (s) +2Al 2 o 3(s) ;

[0031] Particle reinforcement phase: Al 3 Zr (s) and Al 2 o 3(s) ;

[0032] The preparation process is as follows:

[0033] (1) First metal smelting and powder preparation:

[0034] Aluminum alloy 50Kg was melted in a 25kW crucible resistance furnace and heated up to 900°C, degassed and slag removed; all reagents used were fully dried at 300°C, of which Zr(CO 3 ) 2 Grind into fine powder (particle size less than 100 mu m), ready to use after weighing, Zr(CO 3 ) 2 The added weight is 20% of the metal weight (note: the theoretical volume fraction of the particle phase is about 28 vol%).

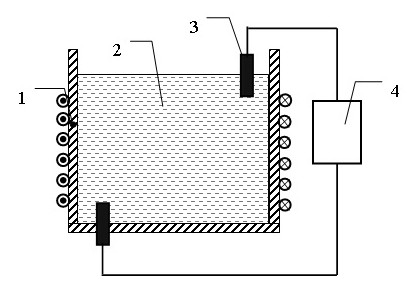

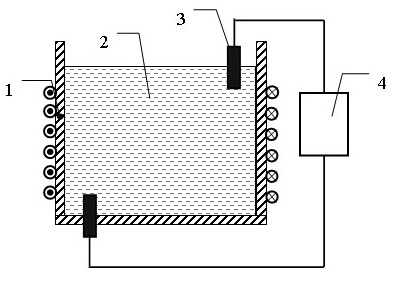

[0035](2): Melt reaction synthesis under pulsed electric field to prepare composite material melt:...

Embodiment 2

[0043] Raw material: matrix magnesium alloy (Mg-11%Al-0.5%Zn-0.2%Mn); reaction salt: K 2 TiF 6 -KBF 4 Powder, refining degassing agent and slag removal agent;

[0044] The preparation process is as follows:

[0045] (1): Metal smelting and powder preparation:

[0046] Mixed salt reagents are fully dried at 250°C to 300°C, of which K 2 TiF 6 -KBF 4 , ground into fine powder (particle size less than 100 mesh), weighed according to 10% of the theoretical weight of the particle-reinforced phase, and then wrapped with aluminum foil for use.

[0047] 2Kg of pure magnesium alloy is melted to 750°C in another crucible melting furnace filled with argon, and at the same time, 0.15% calcium is added to the melt to prevent flames, and NaCl, KCl and MgCl are used to 2 Mix flux.

[0048] (2): In situ reaction synthesis and preparation under pulsed electric field

[0049] After the temperature of the magnesium alloy melt is qualified, the K 2 ZrF 6 -KBF 4 Press into the magnesi...

Embodiment 3

[0052] Raw materials: base metal: 7055 aluminum alloy; reaction salt: K 2 ZrF 6 -KBF 4 (Mass ratio 6.2:7.8) Mixed salt powder, refining degassing agent and slag removal agent;

[0053] The preparation process is as follows:

[0054] (1) First metal smelting and powder preparation:

[0055] 100Kg 7055 aluminum alloy is melted in a crucible-type induction furnace and heated to 900°C, degassed, slag removed, and ready for use; all reagents used are fully dried at 250°C-300°C, of which K 2 ZrF 6 -KBF 4 , to be ground into fine powder (particle size less than 200 mesh), the added weight is 20% of the metal weight.

[0056] (2): Melt reaction synthesis under pulsed electric field to prepare composite material melt:

[0057] After the melt temperature is qualified, a refining is carried out, and the melt that has been refined and meets the temperature requirement (900°C) is poured into the melt reaction synthesizer 1 with heat preservation function, and the solid reactant is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com