Anode material of composite silicate and preparation method thereof

A composite silicate and positive electrode material technology, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problem of poor overcharge resistance of layered excessive metal oxides, low theoretical capacity of olivine-type lithium iron phosphate, and spinite Poor high-temperature performance of stone-type lithium manganate, etc., to achieve the effect of being convenient for large-scale production, excellent electrochemical performance, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

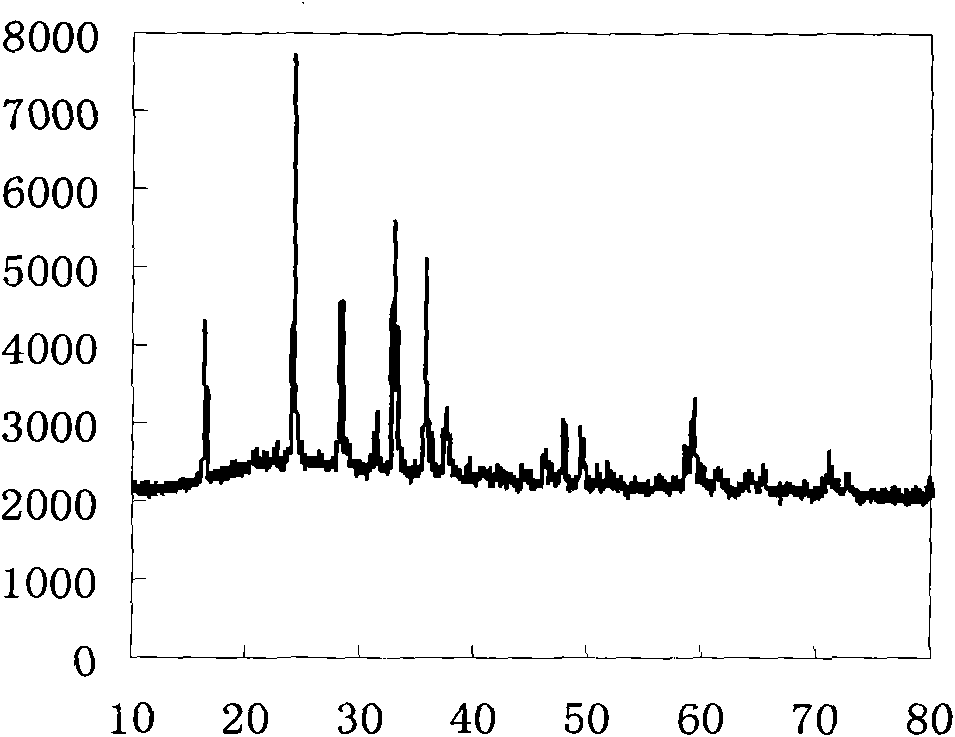

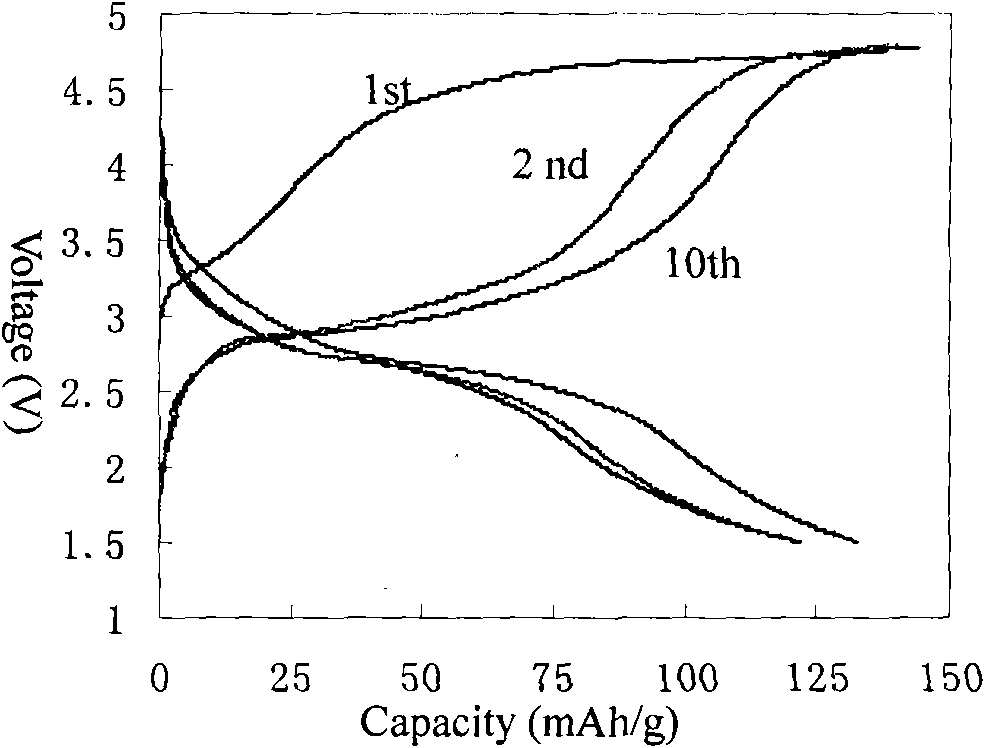

[0033] Accurately weigh 200g of nano-silica, 600g of ferrous oxalate, 687g of lithium acetate, and 40g of glucose, add 2L of deionized water and stir for 1 hour. It was transferred to a ball mill, ball milled at a speed of 500r / min for 10h, and taken out to obtain a uniformly mixed slurry. Then, it is spray-dried and granulated under the condition of 200° C. to obtain a precursor of uniform spheroidized particles. Put the sprayed precursor in the furnace, use nitrogen as the protective atmosphere, the nitrogen flow rate is 6L / min, and the furnace temperature is raised to 650°C at a heating rate of 5°C / min, and then sintered at 650°C for 12h, to be cooled After reaching room temperature, grind the product through a 400-mesh sieve to obtain Li 2 FeSiO 4 / C cathode material. Its carbon content is about 4.5%, such as figure 1 Shown is XRD showing no impurity phases, such as figure 2 As shown, the particle size distribution of the material prepared by this method is excellent...

Embodiment 2

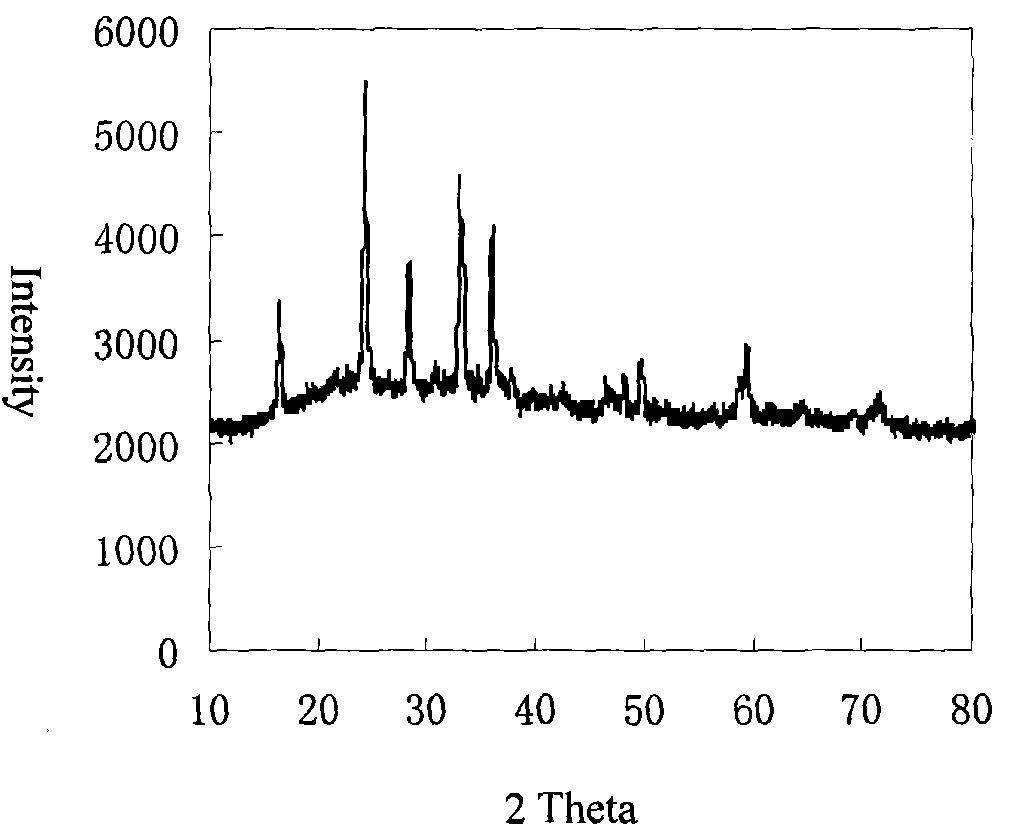

[0035] Accurately weigh 200g of nano-silica, 270g of ferric oxide, 687g of lithium acetate, and 80g of glucose, add 2L of deionized water and stir for 1 hour. It was transferred to a ball mill, ball milled at a speed of 500r / min for 10h, and taken out to obtain a uniformly mixed slurry. Then, it is spray-dried and granulated under the condition of 200° C. to obtain a precursor of uniform spheroidized particles. Put the sprayed precursor in the furnace, use nitrogen as the protective atmosphere, the nitrogen flow rate is 6L / min, and the furnace temperature is raised to 650°C at a heating rate of 5°C / min, and then sintered at 650°C for 12h, to be cooled After reaching room temperature, grind the product through a 400-mesh sieve to obtain Li 2 FeSiO 4 / C cathode material. Its carbon content is about 4.3%, XRD shows that there is no impurity phase, the particle size distribution of the material prepared by this method is excellent, the electrochemical performance is good, and t...

Embodiment 3

[0037] Accurately weigh 715g ethyl orthosilicate, 600g ferrous oxalate, 687g lithium acetate, 80g glucose, add 2L deionized water and stir for 1 hour. It was transferred to a ball mill, ball milled at a speed of 500r / min for 10h, and taken out to obtain a uniformly mixed slurry. Then, it is spray-dried and granulated under the condition of 200° C. to obtain a precursor of uniform spheroidized particles. Put the sprayed precursor in the furnace, use nitrogen as the protective atmosphere, the nitrogen flow rate is 6L / min, and the furnace temperature is raised to 650°C at a heating rate of 5°C / min, and then sintered at 650°C for 12h, to be cooled After reaching room temperature, grind the product through a 400-mesh sieve to obtain Li 2 FeSiO 4 / C cathode material. Its carbon content is about 4.3%, XRD shows that there is no impurity phase, the particle size distribution of the material prepared by this method is excellent, the electrochemical performance is good, and the capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com