Lead ion imprinting integral column and preparation method thereof

A lead ion, monolithic column technology, applied in the field of lead ion imprinted monolithic column and preparation, to achieve the effect of high adsorption capacity and selective identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

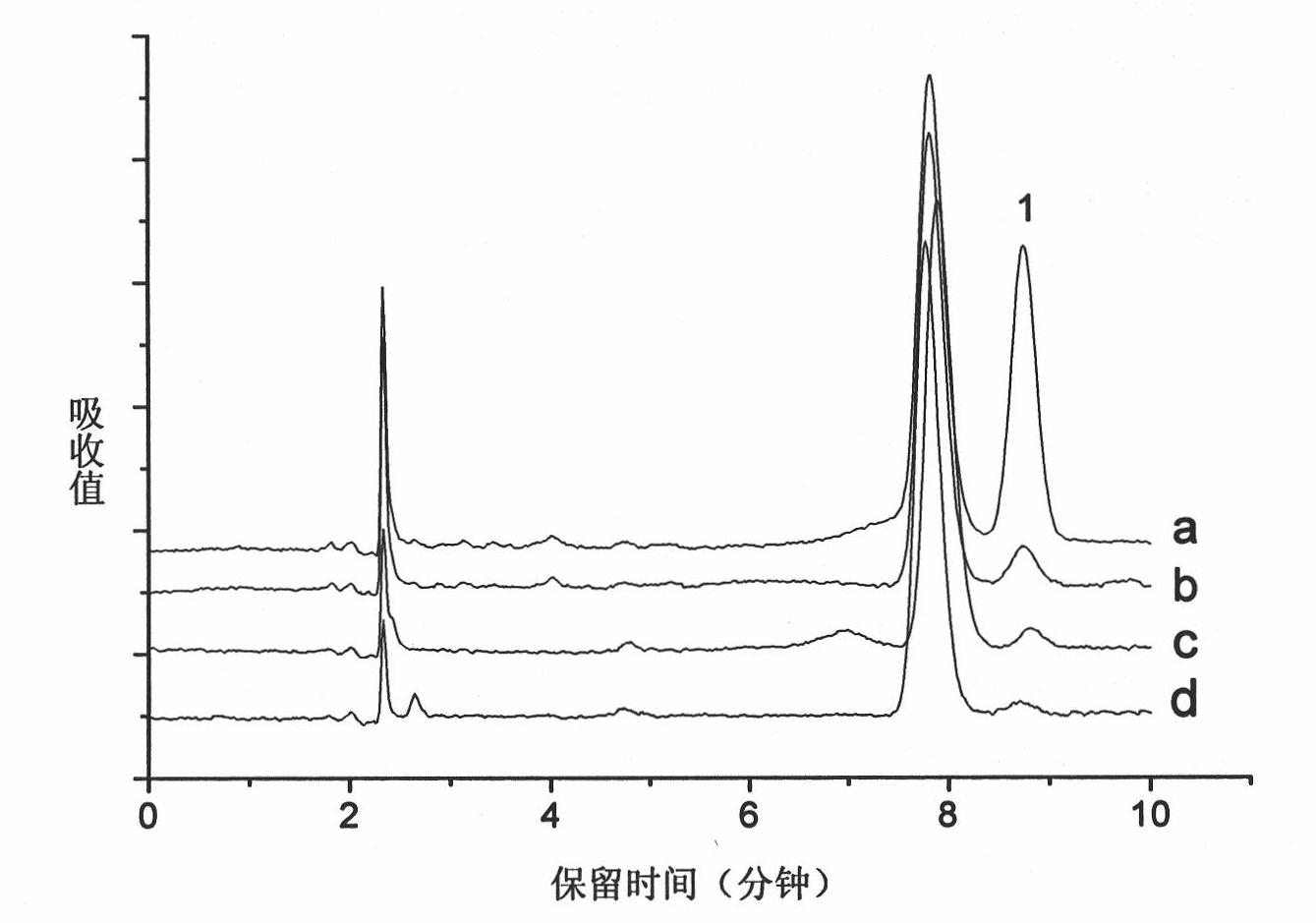

[0021] Experimental example 1: the embodiment of the present invention is connected on the pump of high performance liquid chromatography (HPLC) as chromatographic column, and preparation lead ion concentration is 3.3784 * 10 -7 mol / L solution as the mobile phase, measure 300mL and pass through the embodiment of the present invention at a flow rate of 0.4mL / min, then wash the column with pure water at a flow rate of 0.4mL / min to wash away the remaining unadsorbed lead ions. Finally, change the nitric acid of 0.5mol / L to elute the lead ion adsorbed by the chromatographic column at a flow rate of 0.2mL / min, collect the eluent 10mL, and pass through 4-sulfonic acid phenylporphyrin C 44 h 34 N 4 o 20 S 6 (TPPS4) adopts HPLC analysis after derivatization, and its chromatogram is as follows figure 2 It is shown in spectrum a.

[0022] Control experiment: replace the chromatographic column with a non-imprinted monolithic column (no template was added during synthesis), collect...

experiment example 2

[0024] Experimental example 2: selectivity experiment, connect the embodiment of the present invention on the HPLC pump, and prepare three kinds of ions of Pb(II), Cu(II), and Cd(II) whose concentration is 3.3784×10-7mol / L The mixed solution is used as the mobile phase, measure 300mL and pass it through the chromatographic column at a flow rate of 0.4mL / min, and then wash the chromatographic column with pure water at a flow rate of 0.4mL / min for 1h to wash away the residue in the chromatographic column that is not adsorbed by the chromatographic column. Ions, and finally change to 0.5mol / L nitric acid for elution, and collect 10mL of the eluent solution. 4-sulfophenylporphyrin C 44 h 34 N 4 o 20 S 6 (TPPS4) was derivatized and analyzed by HPLC, and the elution concentration of Pb(Ⅱ) was 4.63×10 -6 mol / L, copper ions and cadmium ions were not detected, indicating that the embodiment of the present invention has strong selective adsorption, and can be used for the enrichmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com