Non-refrigerating infrared focal plane array as well as preparation method and application thereof

A focal plane array and uncooled infrared technology, which is applied in the field of infrared and thermal sensing, can solve the problems of poor system shock resistance, difficulty in machine integration, and bulky optical readout system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Figure 7 The flow chart for the preparation of a MOSFET readout micro-cantilever infrared focal plane array, the specific steps are as follows:

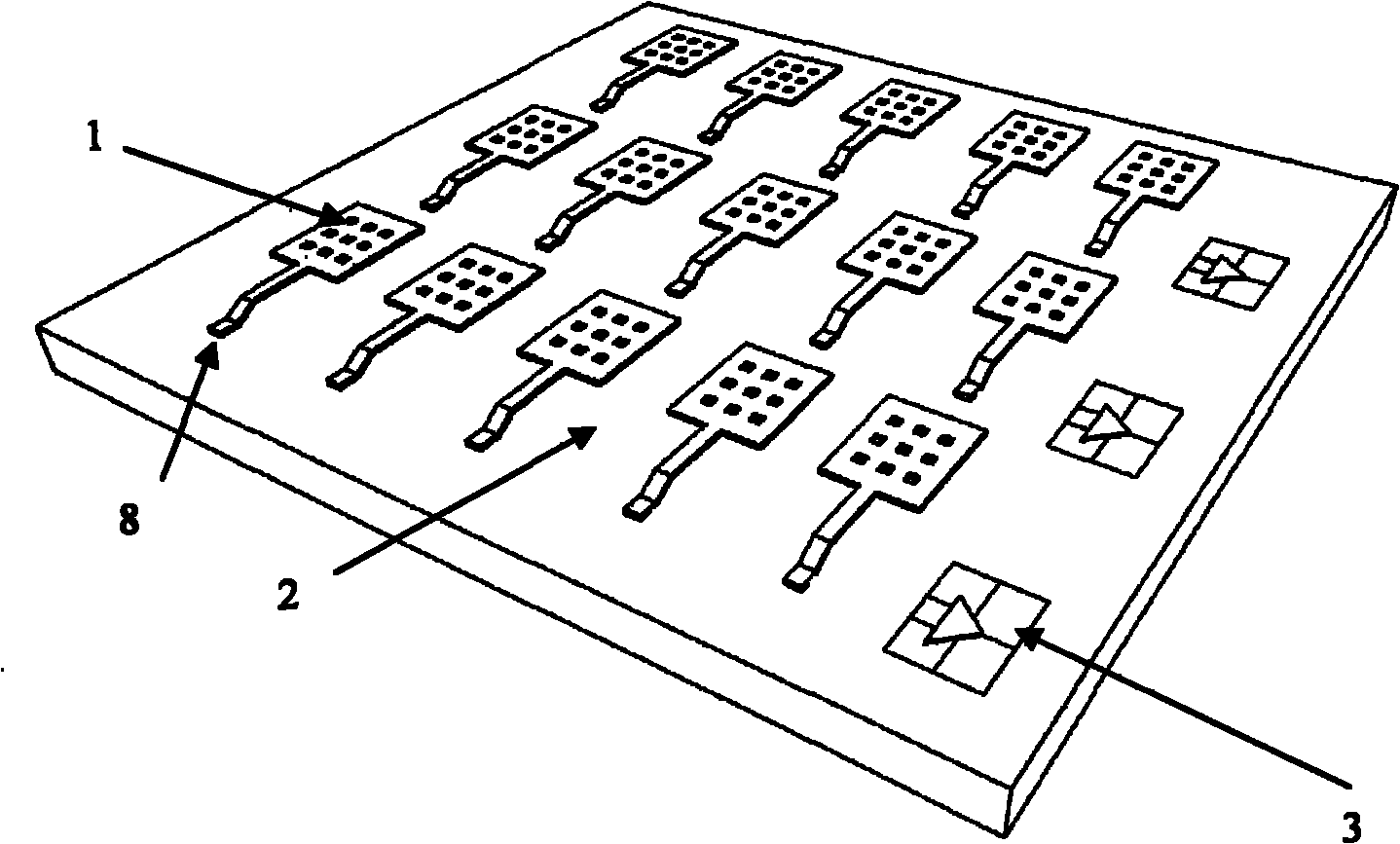

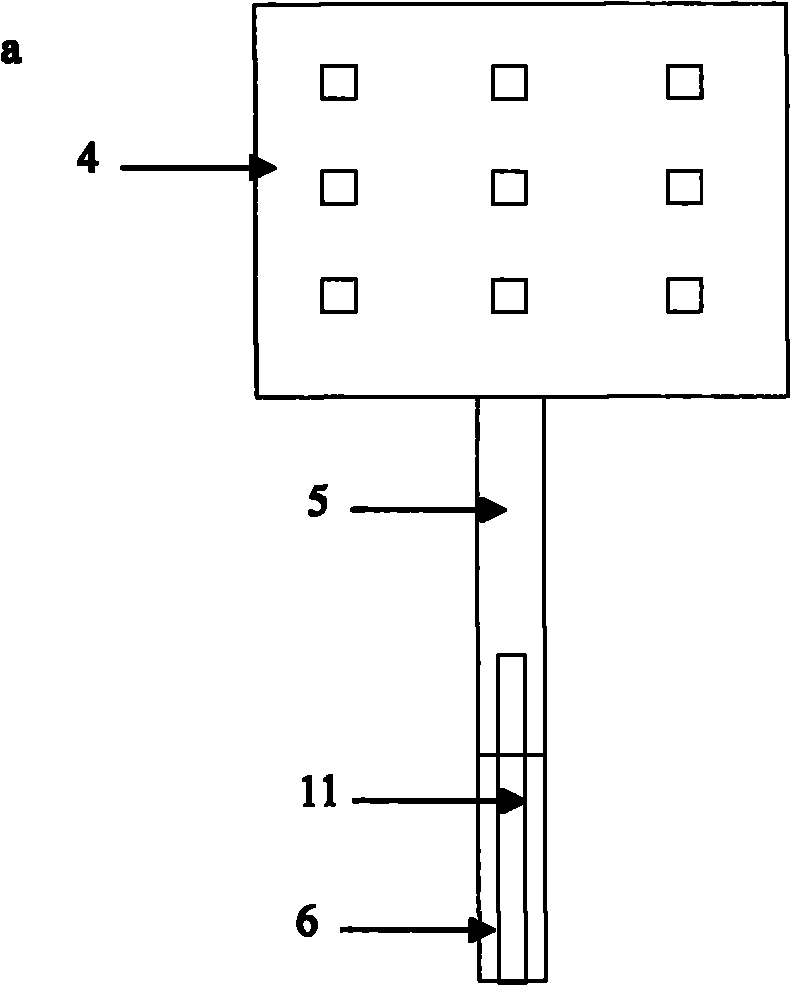

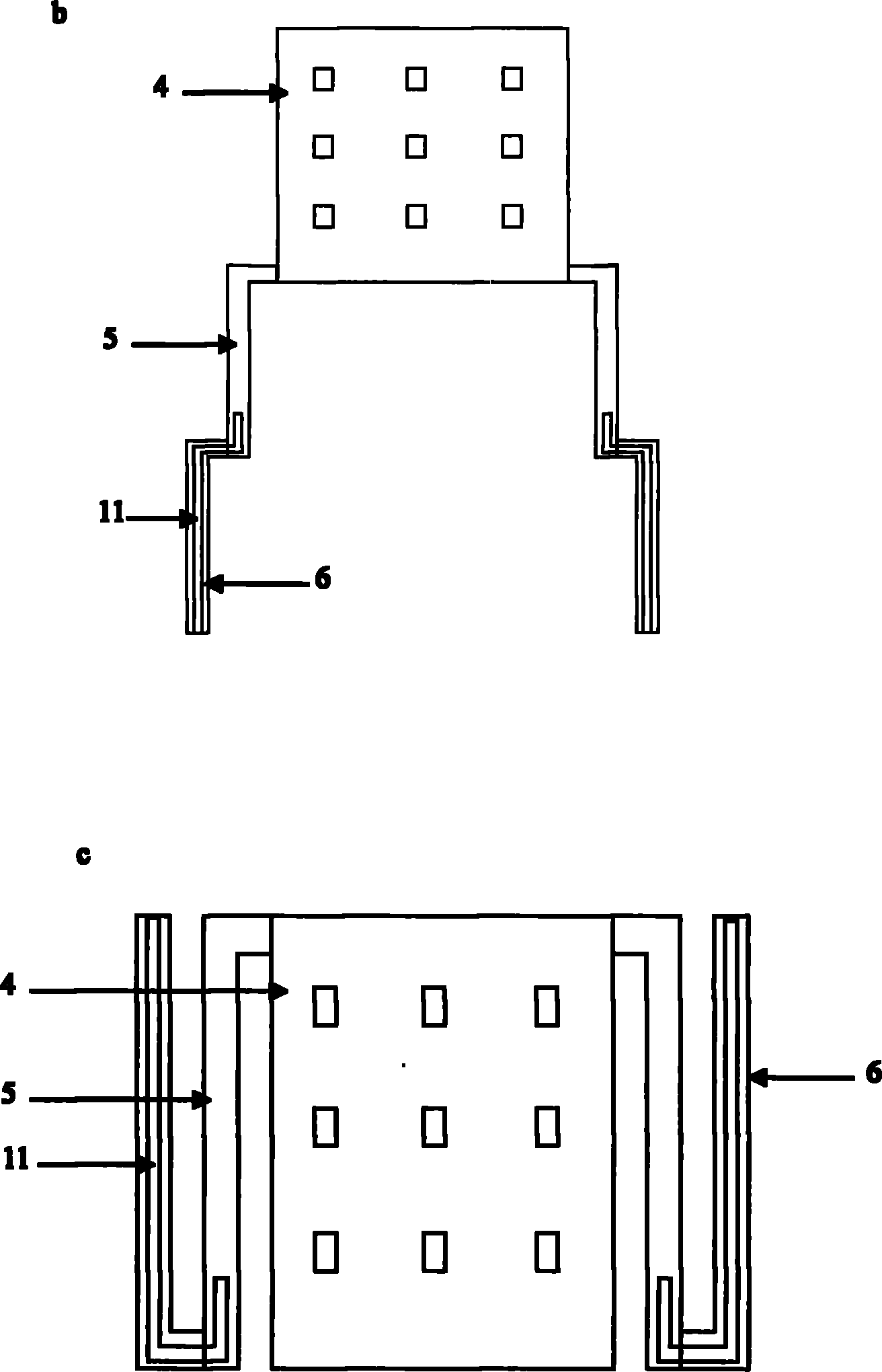

[0068] 1) Adopt SOI silicon wafer 1 as processing substrate, device layer 2 is P-type, device layer 2 thickness is 200nm, (100) crystal orientation, buried oxide layer 3 thickness is 400nm ( Figure 7 a); first, 30nm silicon device layer is oxidized to provide a stress buffer layer for the subsequent process; a layer of SiNx is LPCVD on the surface of the SOI silicon wafer, with a thickness of 100nm, and the first photolithography is performed, and the SiNx is dry etched, and the photolithography is removed Glue to form the active region 4 of the MOSFET device;

[0069] 2) Oxidize the Si device layer to form silicon islands 4 in the active area electrically insulated from each other; carry out the second photolithography, implant boron ions in the active area, the implantation voltage is 40keV, and the dose is 2×10 12 / cm ...

Embodiment 2

[0078] Follow the steps below to prepare a MOSFET readout uncooled infrared focal plane array:

[0079] 1) Using SOI silicon wafer 1 as the processing substrate, the device layer 2 is N-type, the thickness of the device layer 2 is 400nm, (100) crystal orientation, and the thickness of the buried oxide layer 3 is 1 μm ( Figure 7 a); first carry out 50nm silicon device layer oxidation; LPCVD a layer of SiNx on the surface of the SOI silicon wafer with a thickness of 100nm, perform photolithography for the first time, dry etch SiNx, and remove the photoresist;

[0080] 2) Oxidize the Si device layer to form silicon islands 4 in the active area electrically insulated from each other; carry out the second photolithography, implant boron ions in the active area, the implantation voltage is 40keV, and the dose is 1×10 11 / cm 2 , form the P-region 5, remove the photoresist; carry out the third photolithography, inject phosphorus, the implantation voltage is 60kev, and the implantati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com