Method for producing spherical aluminium powder for p-type aluminum-doped back electrodes of crystalline silicon solar cells

A solar cell and spherical aluminum powder technology, which is applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of poor aluminum-silicon adhesion, increased resistance, and the inability to stably produce special spherical aluminum powder, and achieve high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

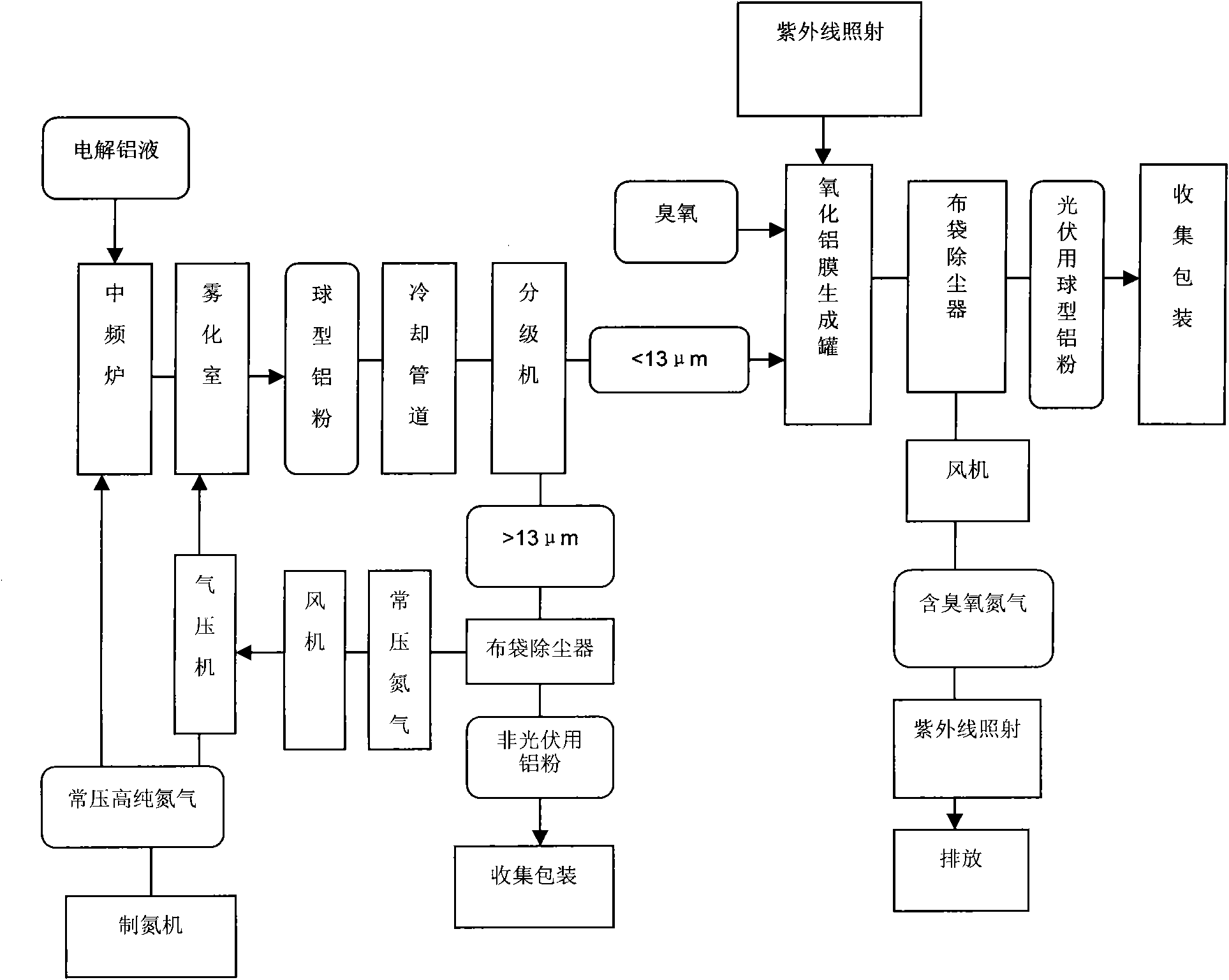

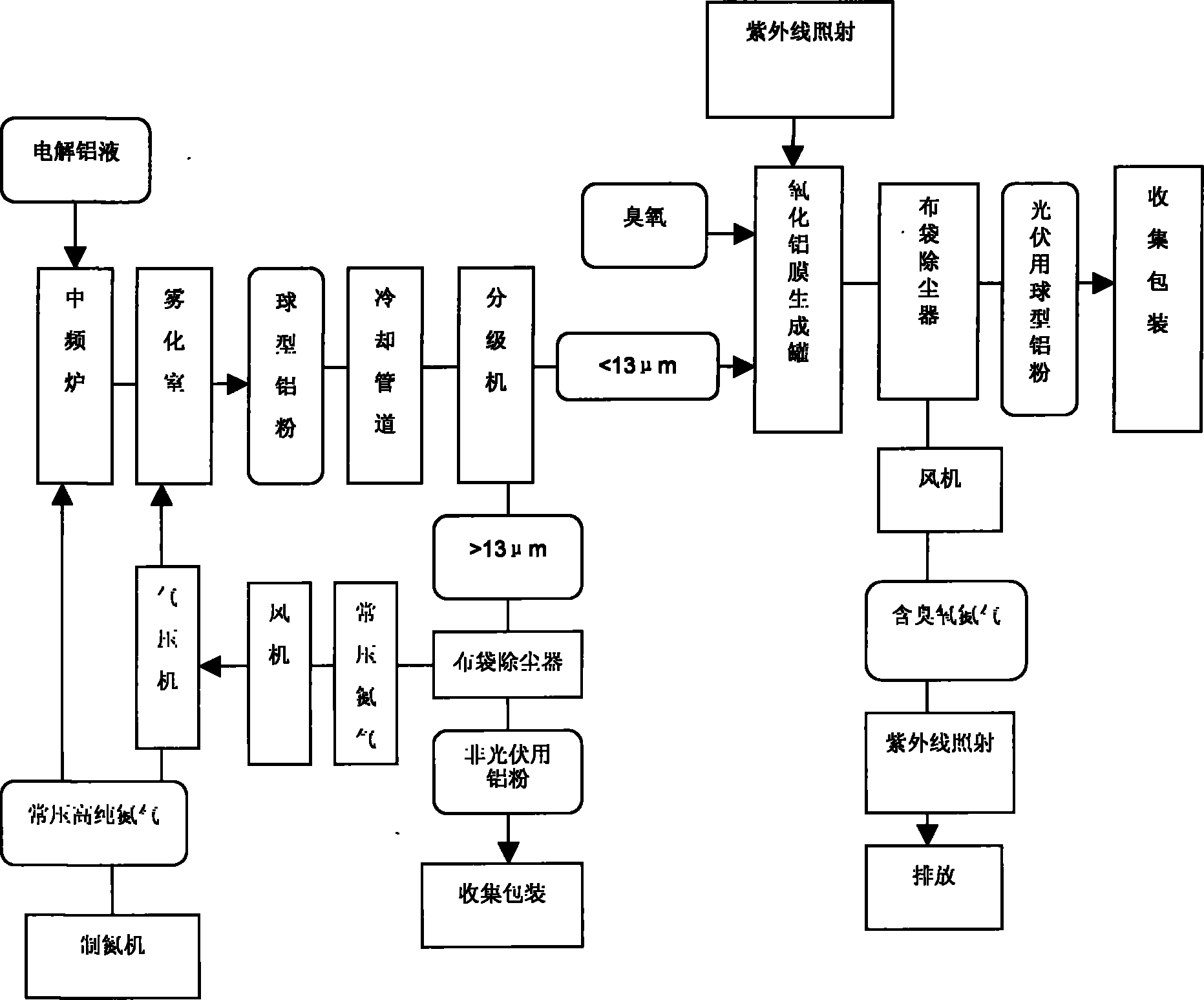

Image

Examples

Embodiment Construction

[0013] 1) Inspection of production system

[0014] The production system composed of each equipment is tested, and the air tightness test is carried out between the equipment of "atomization chamber-cooling pipeline-classifier-gas particle conveying pipe-alumina film generation tank-bag filter-discharge port" , there must be no gas leakage; check the metal connection and grounding of the entire equipment, and the resistance between any two points on the pipeline and the container is less than 3 ohms to prevent static sparks.

[0015] 2) Configuration of molten aluminum

[0016] Select an aluminum electrolyte with a metal aluminum content > 99.8% from the electrolytic aluminum tank, suck it out with a vacuum aluminum bag and put it into an intermediate frequency furnace for refining, so that the silicon content is 99.8%. During the whole process, nitrogen with a purity of more than 99.99% is introduced into the intermediate frequency furnace to isolate the air and prevent oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com