Heat-storage and thermo-regulated fiber

A technology of heat storage and temperature adjustment, fiber, applied in the direction of fiber chemical characteristics, conjugated artificial filament, conjugated synthetic polymer artificial filament, etc., can solve the problem of fiber use effect and range limitation, poor heat resistance stability, heat enthalpy Small and other problems, to achieve good heat storage and temperature adjustment performance, good electrical conductivity, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

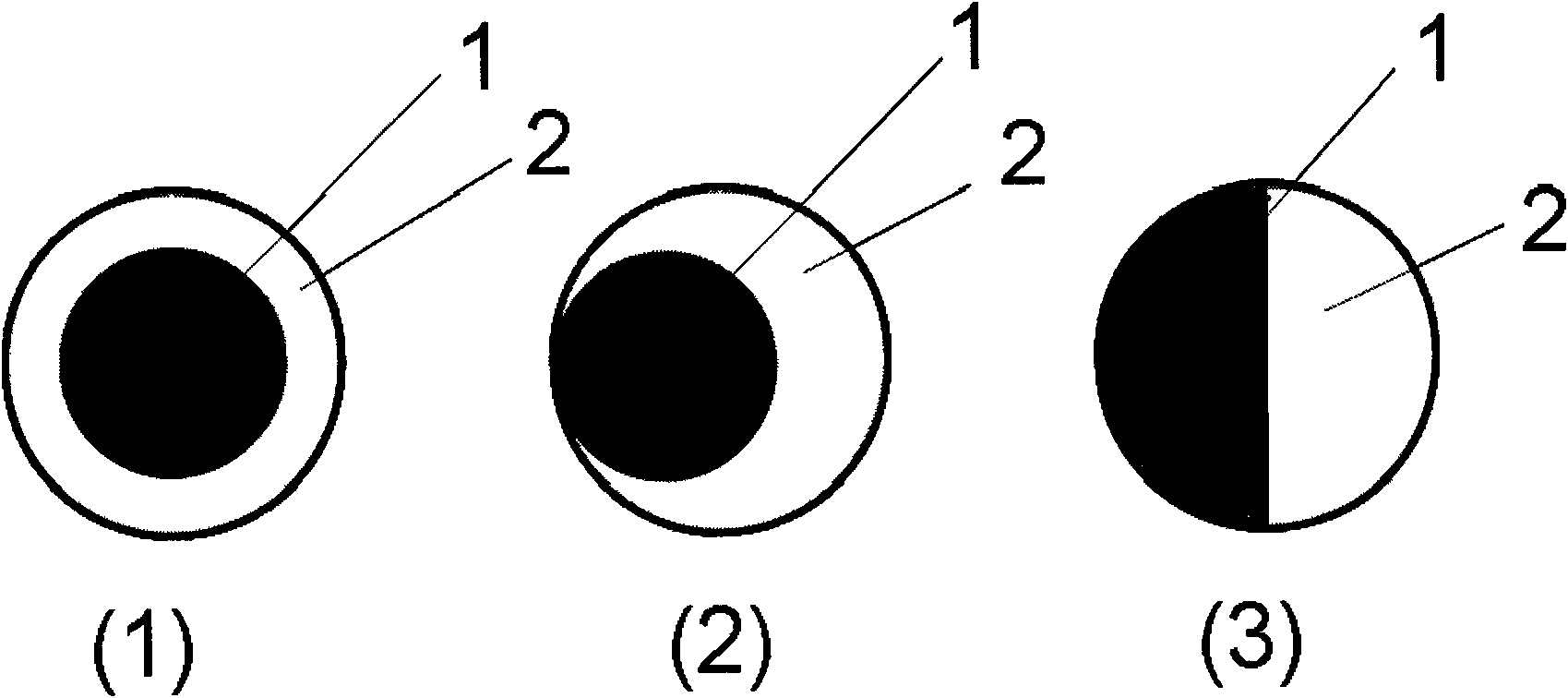

[0022] The preparation method of the fiber of the present invention adopts the melt composite spinning method, which is basically the same as the prior art. According to the composition of the fiber of the present invention, it mainly includes the following steps:

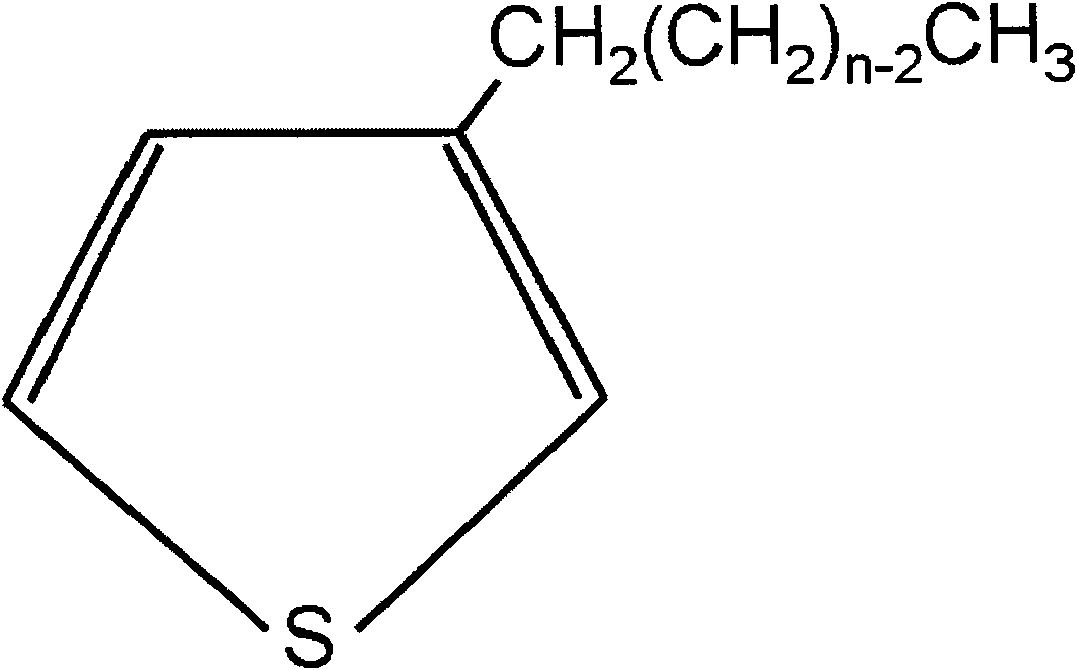

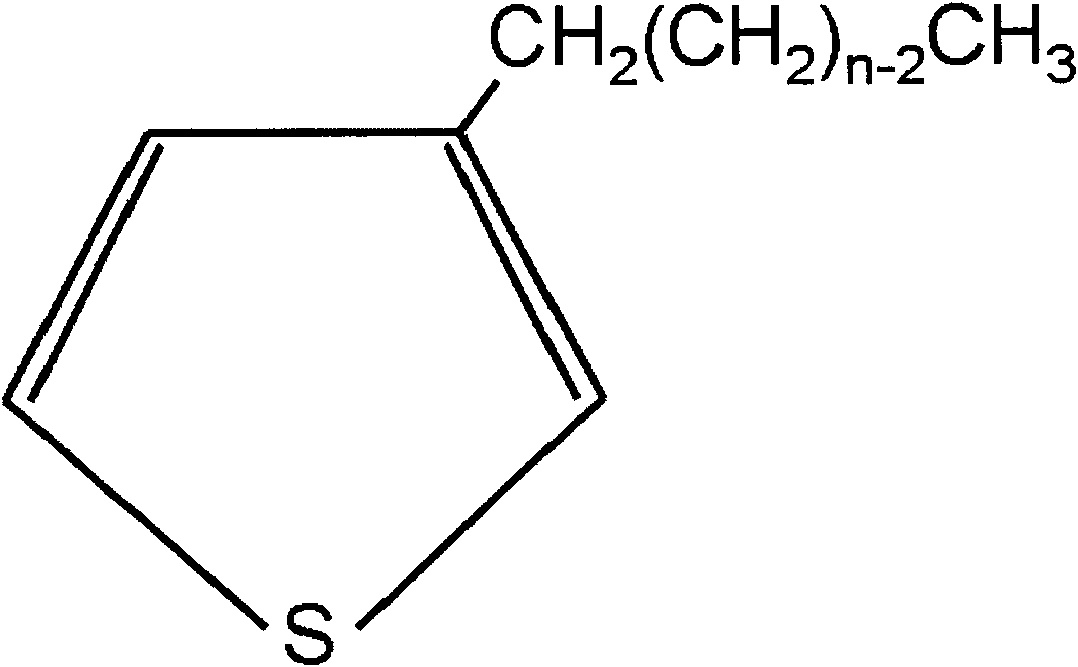

[0023] (1) Homopolymer or copolymer of the comb-shaped polymer phase change material 3-alkylthiophene, which is synthesized by oneself or bought in the market, or the mass ratio of the component A is 20~80:80~20 The homopolymer blend, after drying, removes the moisture in it, so that the moisture content reaches 50-150ppm;

[0024] (2) Transport the homopolymer, copolymer or homopolymer blend of the poly(3-alkylthiophene) to the A component metering pump of the fiber after melting by known technology, and control the quality of the A component of the fiber The percentage content is 20-60%;

[0025] (3) Using known technology to dry the fiber-forming polymer of the B component to remove moisture, so that the moistu...

Embodiment 1

[0036] A random copolymer of 3-hexadecylthiophene and 3-octadecylthiophene (average degree of polymerization 21) with a molar ratio of 20:80 is used as component A of the fiber, and polycaprolactam (intrinsic viscosity 0.75) is used as the fiber In component B, both components are dried until the moisture content is lower than 100ppm, the mass ratio of A and B is controlled to be 40:60, and the concentric circular sheath-core composite spinning is made at 250°C to make spun yarn, which is further processed into elastic yarn.

[0037] After inspection, the fineness of the finished fiber is 132dtex / 78f, the tensile breaking strength is 3.4cN / dtex, and the elongation at break is 35%. 27°C, the heat release is 29J / g; 5% thermal weight loss temperature is 295°C; the surface specific resistance of the fiber is 3200Ω / cm; after using cyclohexane as the solvent Soxhlet extractor for extraction or treatment, the weight loss of the fiber is 4%.

Embodiment 2

[0039] A random copolymer of 3-hexadecylthiophene and 3-octadecylthiophene (average degree of polymerization 92) with a molar ratio of 80:20 is used as the A component of the fiber, and polypropylene (melt index 35g / 10min) is The B component of the fiber, after the two components are dried until the moisture content is lower than 100ppm, the mass ratio of A and B is controlled to be 40:60, melted and spun side by side at 230°C to make as-spun yarn, and further bundled, drawn, crimped, Drying, shaping, cutting, and making short fibers.

[0040] After inspection, the fineness of the finished fiber is 2.4dtex, the tensile breaking strength is 2.9cN / dtex, and the elongation at break is 34%. ℃, the heat release is 19J / g; 5% thermal weight loss temperature is 247 ℃; the surface specific resistance of the fiber is 1.2 / cm; after using cyclohexane as the solvent Soxhlet extractor, the weight loss of the fiber is 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

| Endothermic temperature | aaaaa | aaaaa |

| Heat absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com