Method for high-value and non-waste utilization of cyanidation slag

A cyanidation tailings, high-value technology, applied in the removal of solid waste, etc., can solve the problem of unconsidered emission reduction, achieve high product technical indicators, and achieve the effect of zero waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

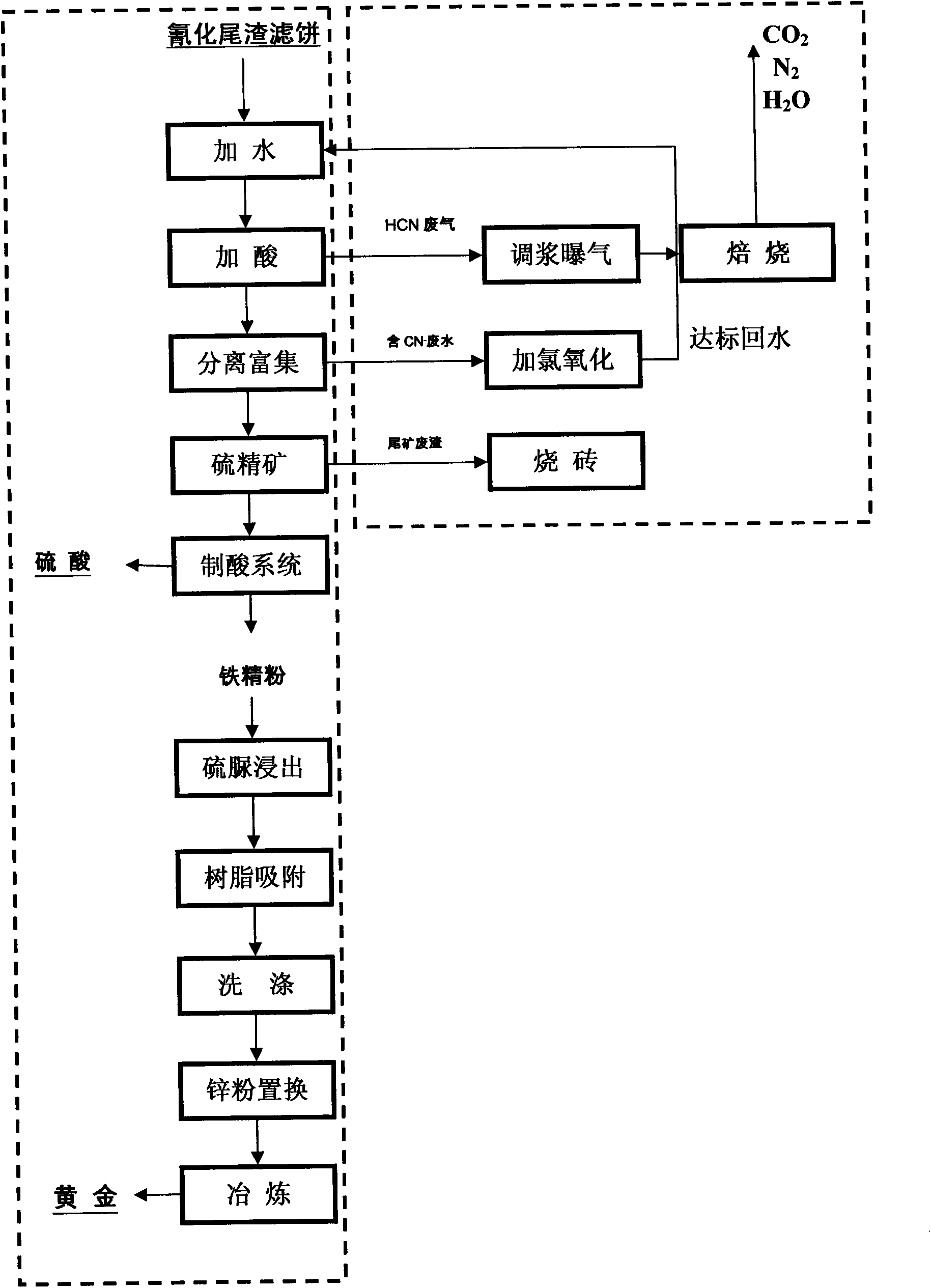

Method used

Image

Examples

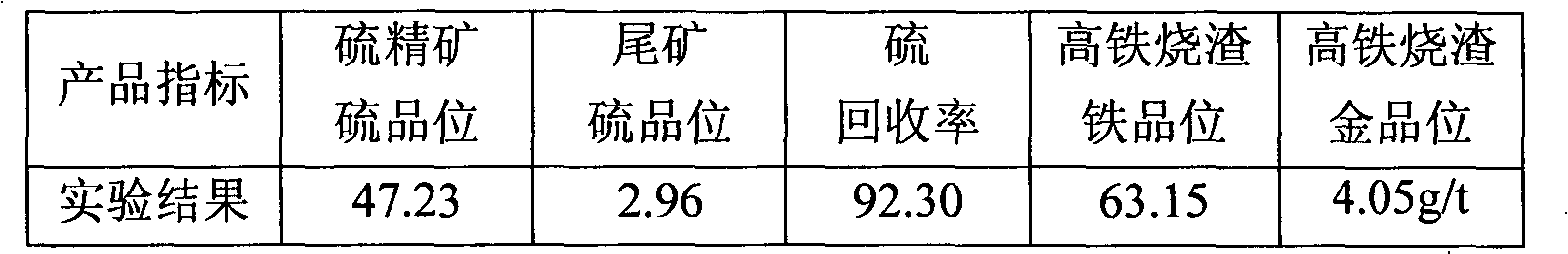

Embodiment 1

[0039] The chemical composition of a gold mine cyanide tailings filter cake is as follows:

[0040] Table 1. Element content (%) of a gold mine cyanide tailings filter cake

[0041] element

S

Fe

Cu

Zn

Pb

As

content

28.26

25.36

0.14

0.15

0.21

0.011

[0042] (1) Add water to the fine-grained refractory high-pollution cyanide tailings through the Cu, Zn, Pb multi-element recovery process and stir in the stirring tank for 10min, the pulp concentration is 30%, add 6wt% dilute sulfuric acid in the pulp and stir for 2min, adjust pH = 5, form A pulp, add 10wt% functional composite sol 500g / tt to A pulp and stir for 2min to form B pulp, first add 240g / t butyl xanthate to B pulp and stir for 2min, then add pinitol oil 20g / t and stirred for 2 minutes to form C pulp, fill the C pulp with air from the bottom of the stirring tank and continue to stir for 1 minute, conduct a rough separation for 10 minutes, scrape...

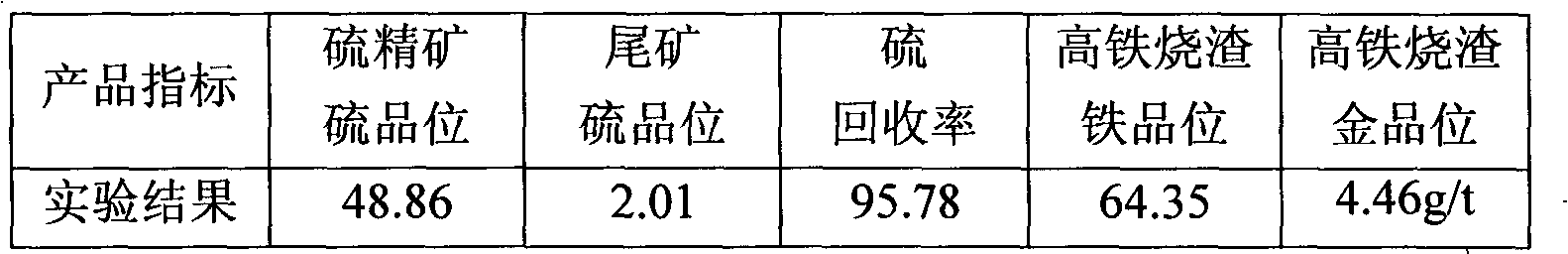

Embodiment 2

[0056] The chemical composition of a gold mine cyanide tailings filter cake is as follows:

[0057] Table 3. Element content (%) of a gold mine cyanide tailings filter cake

[0058] element

S

Fe

Cu

Zn

Pb

As

content

28.26

25.36

0.14

0.15

0.21

0.011

[0059] (1) Add water to the fine-grained refractory high-pollution cyanide tailings through Cu, Zn, Pb multi-element recovery process and stir in the stirring tank for 15min, the pulp concentration is 33%, add 6wt% dilute sulfuric acid in the pulp and stir for 6min, adjust pH = 6, form A pulp, add 10wt% functional composite sol 750g / t to A pulp and stir for 6 minutes to form B pulp, first add butyl xanthate 360g / t to B pulp and stir for 6 minutes, then add pinitol oil 40g / t and stirred for 6min to form C pulp, fill the C pulp with air from the bottom of the stirring tank and continue stirring for 1min, conduct a rough separation for 15min, scrape the upp...

Embodiment 3

[0073] The chemical composition of a gold mine cyanide tailings filter cake is as follows:

[0074] Table 5. Element content (%) of a gold mine cyanide tailings filter cake

[0075] element

S

Fe

Cu

Zn

Pb

As

content

28.26

25.36

0.14

0.15

0.21

0.011

[0076] (1) Add water to the fine-grained refractory high-pollution cyanide tailings through Cu, Zn, Pb multi-element recovery process and stir in the stirring tank for 20min, the pulp concentration is 35%, add 6wt% dilute sulfuric acid in the pulp and stir for 10min, adjust pH=7, form A pulp, add 10wt% functional composite sol 1000g / t to A pulp and stir for 10min to form B pulp, first add 480g / t butyl xanthate to B pulp and stir for 10min, then add pinitol oil 60g / t and stirred for 10 minutes to form C pulp, fill the C pulp with air from the bottom of the stirring tank and continue to stir for 2 minutes, conduct a rough separation for 20 minutes, scrape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com