Method for preparing C/C composite material nanometer silicon carbide-mullite-molybdenum disilicide composite external coating

A technology of nano-silicon carbide and carbon composite materials, which is applied in the field of preparation of nano-silicon carbide-mullite-molybdenum disilicide composite outer coatings of carbon/carbon composite materials, and can solve problems such as easy-to-crack coating thickness and instant noodles Cracking and other problems, to achieve the effect of low cost, high temperature oxidation protection ability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

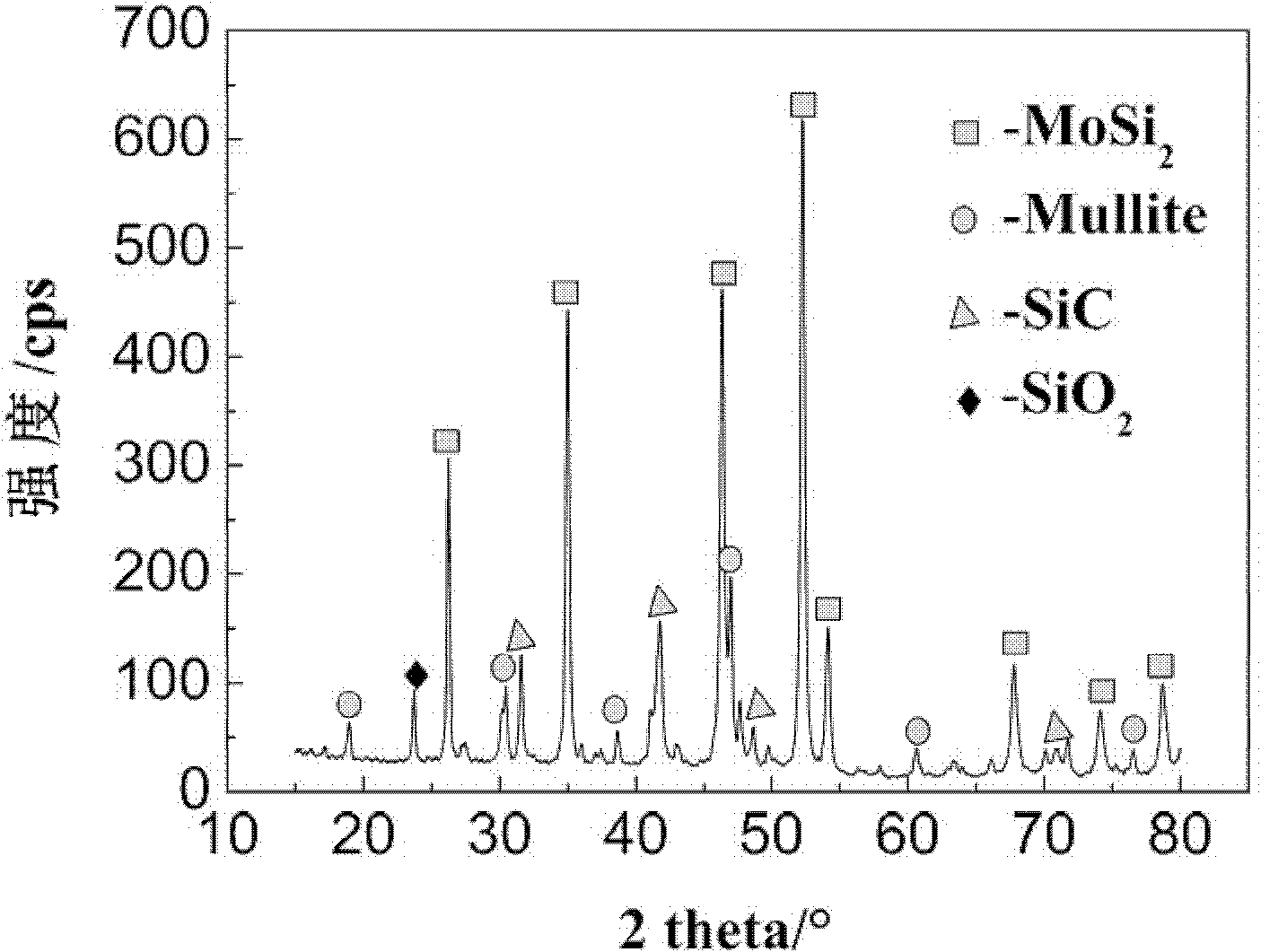

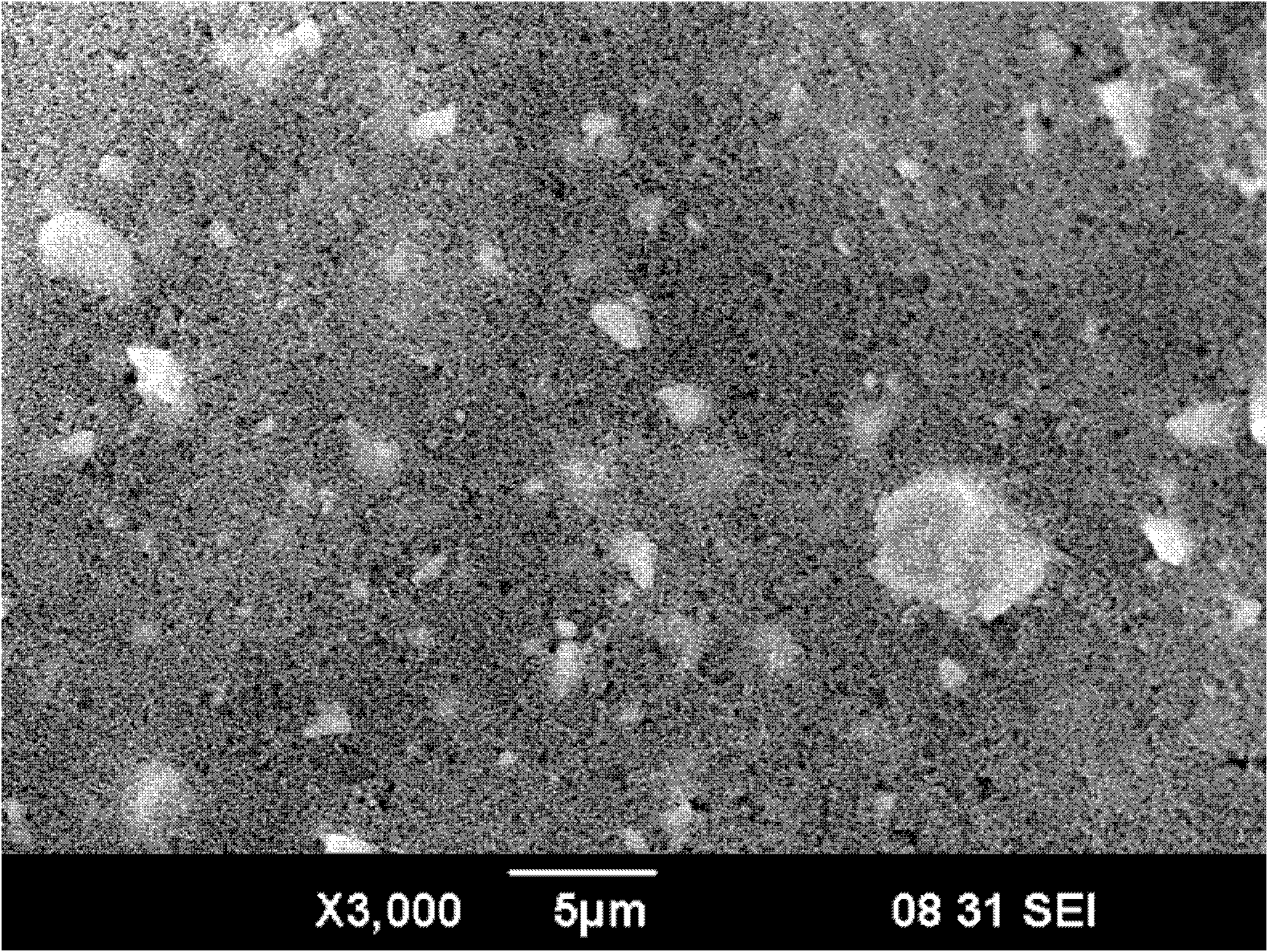

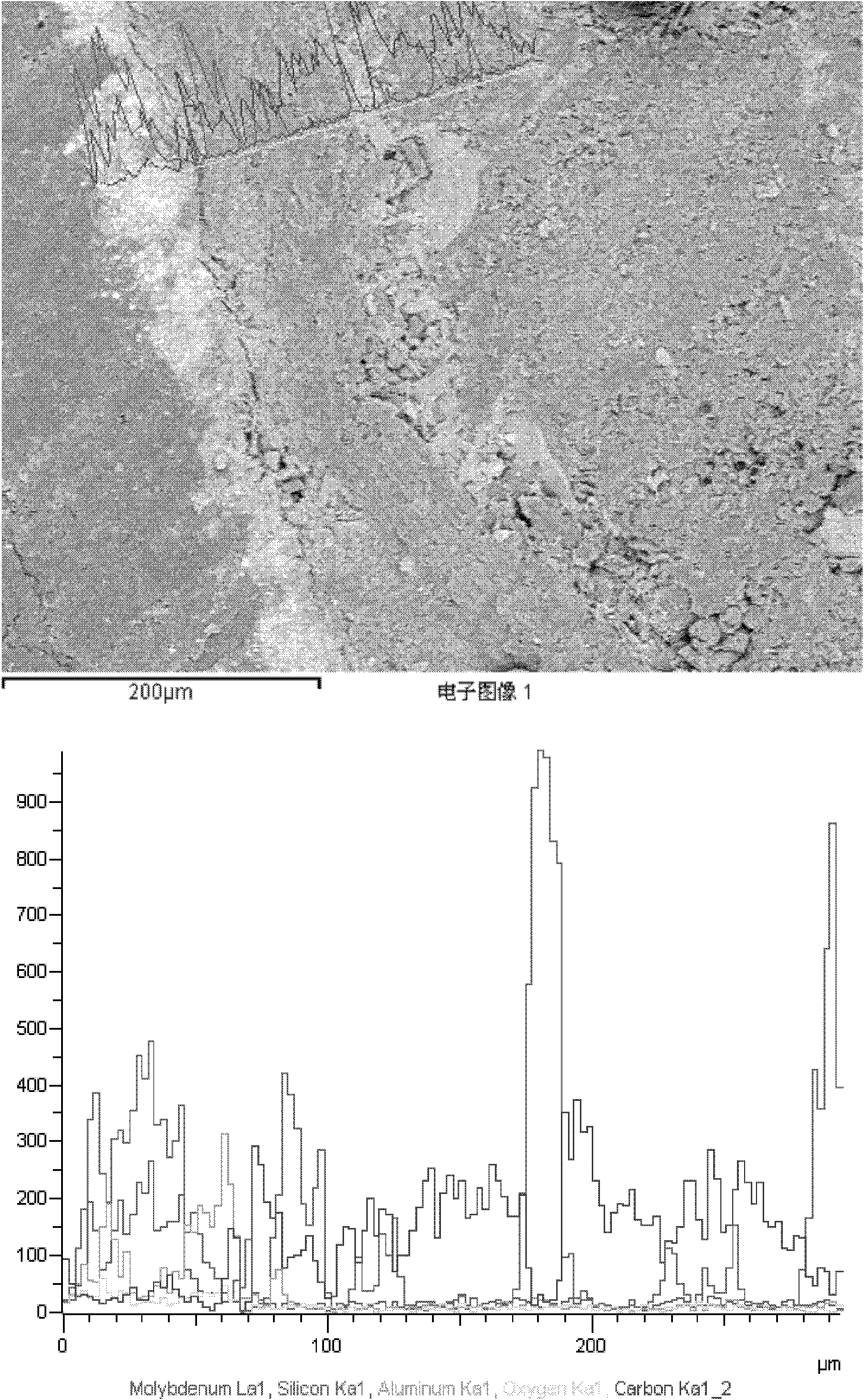

Embodiment 1

[0021] Example 1: 1) Preparation of rod-shaped mullite powder First, 4ml of tetraethyl orthosilicate (SiO 2 %≥28%) dissolved in 20ml of absolute ethanol, and then add 10ml of distilled water, adjust the pH of the solution to 2 with hydrochloric acid, and magnetically stir at room temperature for 0.5h to fully pre-hydrolyze the ethyl orthosilicate, which is counted as solution A; Take 24g of Al(NO 3 ) 3 ·9H 2 O was added to 10ml of distilled water and stirred at room temperature until Al(NO 3 ) 3 ·9H 2 After the O is fully dissolved, pour it into the A solution, place the mixed solution on a magnetic stirrer and stir evenly, then adjust the pH to 4.5 with ammonia water, which is counted as solution B; finally, dry the B solution at 60℃ to become dry Glue, calcining the dry gel in a muffle furnace, set the heating rate to 5°C / min, heat it up to 1150°C, keep it for 2h and then cool it down to room temperature in the furnace to obtain rod-shaped nano-mullite powder; 2) First, add 0....

Embodiment 2

[0023] Example 2: 1) Preparation of rod-shaped mullite powder. First, 6ml of tetraethyl orthosilicate (SiO 2 %≥28%) dissolved in 20ml of absolute ethanol, then add 20ml of distilled water, adjust the pH of the solution to 3 with hydrochloric acid, magnetically stir at room temperature for 1 hour to fully pre-hydrolyze the ethyl orthosilicate, and count it as solution A; 25g of Al(NO 3 ) 3 ·9H 2 O was added to 13ml of distilled water and stirred at room temperature until Al(NO 3 ) 3 ·9H 2 After the O is fully dissolved, pour it into the A solution, place the mixed solution on a magnetic stirrer and stir evenly, then adjust the pH to 5 with ammonia water, which is counted as solution B; finally, dry the B solution at 60°C to dry it Glue, calcining the dry gel in a muffle furnace, set the heating rate to 5°C / min, heat it up to 1150°C, keep it for 2h and then cool it down to room temperature in the furnace to obtain rod-shaped nano-mullite powder; 2) First, add 1g rod-shaped mullite...

Embodiment 3

[0024] Example 3: 1) Preparation of rod-shaped mullite powder. Firstly, 5ml of tetraethyl orthosilicate (SiO 2 %≥28%) was dissolved in 20ml of absolute ethanol, then 15ml of distilled water was added, the pH of the solution was adjusted to 4 with hydrochloric acid, and the ethyl orthosilicate was fully pre-hydrolyzed by magnetic stirring for 1.5h at room temperature, which was counted as solution A; Take 27g of Al(NO 3 ) 3 ·9H 2 O was added to 20ml of distilled water and stirred at room temperature until Al(NO 3 ) 3 ·9H 2 After the O is fully dissolved, pour it into the A solution, place the mixed solution on a magnetic stirrer and stir evenly, then adjust the pH to 5.5 with ammonia water, and count it as solution B; finally, dry the B solution at 60°C to dry it Glue, calcining the dry gel in a muffle furnace, set the heating rate to 5°C / min, heat it up to 1150°C, keep it for 2h and then cool it down to room temperature in the furnace to obtain rod-shaped nano-mullite powder; 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com