Nozzle device of spiral core control flow beam for micro-abrasive air jet machining

A nozzle device and helical core technology, applied in abrasives, explosion generating devices, metal processing equipment, etc., can solve the problem of poor uniformity of velocity distribution inside the flow beam, unable to solve the problem of flow beam control of round-hole nozzles, and flow beam divergence, etc. problem, to achieve the effect of improving shape and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

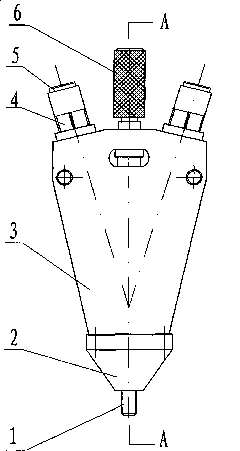

[0014] A nozzle device for controlling flow with a spiral core for microabrasive air jet processing, including a nozzle device body 3, a nozzle seat 2, a nozzle 1, a spiral core 11, a spiral core seat 8, a spiral core balance spring 10, a spiral trimmer 6 and an O-shaped Sealing ring 7,9. The nozzle length is 15mm, the inner hole is Φ1mm, and the material is hard alloy. The nozzle 1 is set in the nozzle seat 2, and the fit is tight to ensure that there is no gas leakage. The nozzle seat 2 is installed on the nozzle device body 3, and the nozzle seat 2 There is an O-ring 9 between the nozzle device body 3, and they are fastened together by bolts. After the nozzle 1 and the nozzle seat 2 are assembled, the inner hole of the nozzle 1 and the installation hole of the nozzle seat 2 are on the same axis . The spiral core 11 is arranged in the nozzle 1, and the spiral core 11 is mounted on the spiral core seat 8 in the nozzle seat 2 with an interference fit. The helix angle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com