Preparation method of TiAl alloy with fine grain full synusia tissue

A layered and fine-grained technology, which is applied in the field of TiAl alloy preparation, can solve the problems of difficult casting of TiAl alloy and high cost of preparation methods, and achieve the effects of cost reduction, good mechanical properties, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

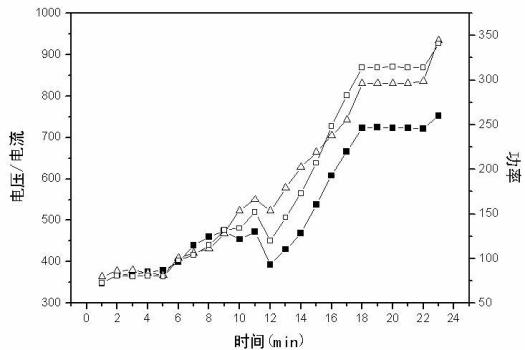

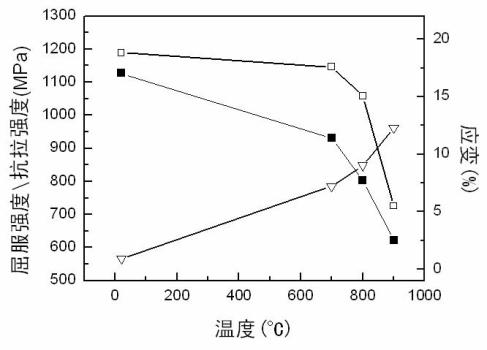

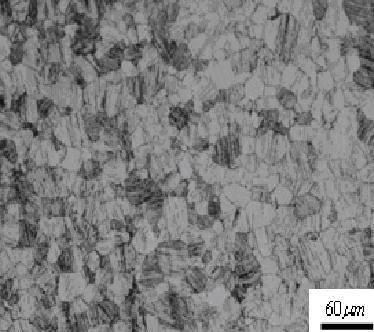

[0009] Specific Embodiment 1: The preparation of the TiAl alloy with fine-grained full-layer lamellar structure in this embodiment is carried out according to the following steps: 1. Melting: adopt a water-cooled copper crucible induction melting method to obtain a TiAl alloy ingot, wherein Al in the TiAl alloy ingot is 42at.%~43at.%; 2. Hot isostatic pressing: TiAl alloy ingots are kept at a temperature of 1250-1280°C and a pressure of 130-140MPa for 4-5 hours, and then cooled out of the furnace; 3. EDM Wire cutting: Cut the TiAl alloy ingot obtained after hot isostatic pressing into a cylindrical ingot; 4. Sheath sealing welding: spray the glass lubricant with a thickness of 0.1 to 0.15mm on the surface of the cylindrical ingot, Then wrap the aluminum silicate fiber with a thickness of 2-7mm to obtain the matrix, then place the matrix in the middle of the stainless steel pipe and weld the two ends of the stainless steel pipe with stainless steel plates with a thickness of 2-7...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment is different from Embodiment 1: in step 1, Al in the TiAl alloy ingot is 42 at.%; other steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

[0012] Embodiment 3: This embodiment is different from Embodiments 1 to 2: In step 2, the temperature is 1270° C. and the pressure is 135 MPa, and the temperature is kept for 4.5 hours. Other steps and parameters are the same as those in Embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com