Sealant for acrylic ester modified solar photovoltaic module and preparation method thereof

A solar photovoltaic and acrylate technology, applied in photovoltaic power generation, chemical instruments and methods, adhesives, etc., can solve problems such as unseen technical inspiration and unheard commercial success reports, etc., and meet process requirements and equipment. Not harsh, simple craftsmanship, ideal weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

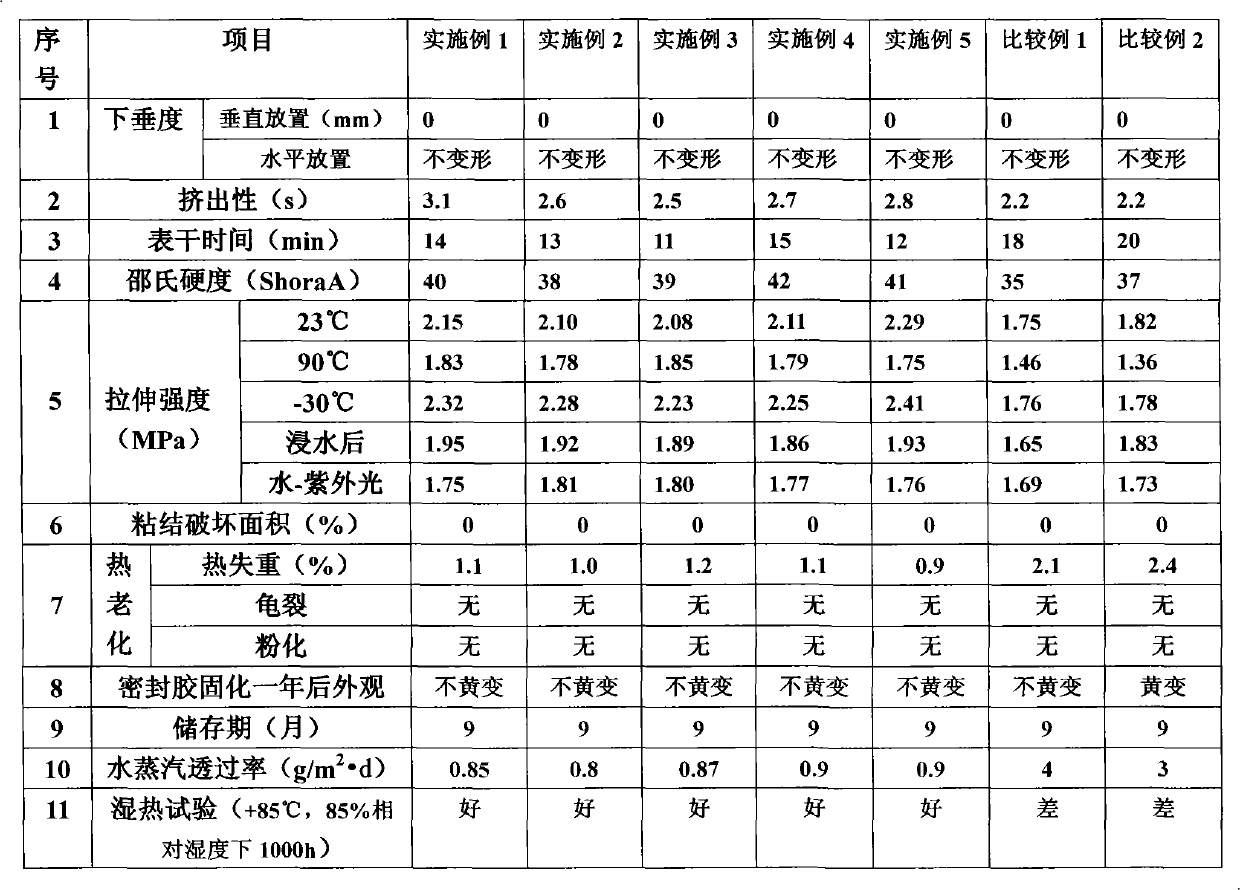

Embodiment 1

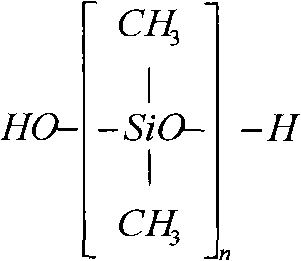

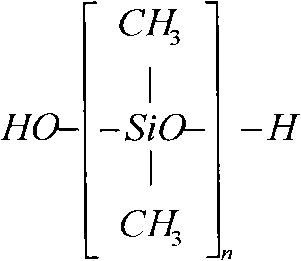

[0035] A) prepare the base material, 90 parts of α, ω-dihydroxy polydimethylsiloxane, 10 parts of methyl methacrylate and the chemical compound prepared by Changshu Institute of Technology, Jiangsu Province, China are preferably prepared according to the weight ratio or parts by weight. The brand LGHC-A type cadmium telluride mixed catalyst developed with the School of Materials Engineering and sold to the outside world is 0.5 parts of the catalyst A defined in the present invention, which is added to the vacuum kneader for kneading. The temperature is controlled at 120°C, the kneading time is controlled at 120min, and 100.5 parts of the base material are obtained;

[0036] B) prepare sealant, earlier by the base material 100.5 parts that step A) obtains, process through resin acid and be the activated calcium carbonate 20 of XL-3 type by the trade mark that China Henan Province Keli New Material Co., Ltd. produces and sells Parts, 40 parts of silica powder with a particle siz...

Embodiment 2

[0038] A) Prepare the base material, mix 90 parts of α, ω-dihydroxypolydimethylsiloxane, methyl acrylate, ethyl acrylate, and butyl acrylate in a ratio of 4:4:5 Proportioning, a total of 13 parts and preferably developed by the School of Chemistry and Materials Engineering, Changshu Institute of Technology, Jiangsu Province, China and sold to the outside world is LGHC-A type cadmium telluride mixed catalyst, that is, 0.7 parts of catalyst A defined in the present invention are added to the vacuum kneading Kneading in the machine, the vacuum degree of the vacuum kneader is controlled at 0.09MPa, the kneading temperature is controlled at 130°C, and the kneading time is controlled at 150min to obtain 103.7 parts of the base material;

[0039] B) prepare sealant, earlier by the base material 103.7 parts that step A) obtains, through resin acid treatment and the brand that is produced and sold by Henan Keli New Material Co., Ltd., Henan Province, China is the active calcium carbonat...

Embodiment 3

[0041] A) Preparation of base material, 90 parts of α, ω-dihydroxy polydimethylsiloxane, ethyl methacrylate, butyl methacrylate, glycidyl methacrylate Esters are in a ratio of 1:1:1, a total of 12 parts and preferably developed by the School of Chemistry and Materials Engineering, Changshu Institute of Technology, Jiangsu Province, China and sold externally as LGHC-A type cadmium telluride mixed catalyst, which is catalyst A as defined in the present invention. .6 parts were added to a vacuum kneader and kneaded. The vacuum degree of the vacuum kneader was controlled to be 0.08MPa, the kneading temperature was controlled to be 125°C, and the kneading time was controlled to be 145min to obtain 102.6 parts of base material;

[0042] B) prepare sealant, earlier by the base material 102.6 parts that step A) obtains, process through resin acid and be the activated calcium carbonate 25 of XL-3 type by the trade mark that China Henan Province Keli New Material Co., Ltd. produces and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com