Preparation method of alumina oxide matrix porous ceramic material

A technology of alumina ceramic powder and alumina, which is applied in the field of ceramic materials, can solve problems such as difficult to obtain pure alumina porous ceramic materials, and achieve the effects of saving the use of sintering aids, saving costs, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

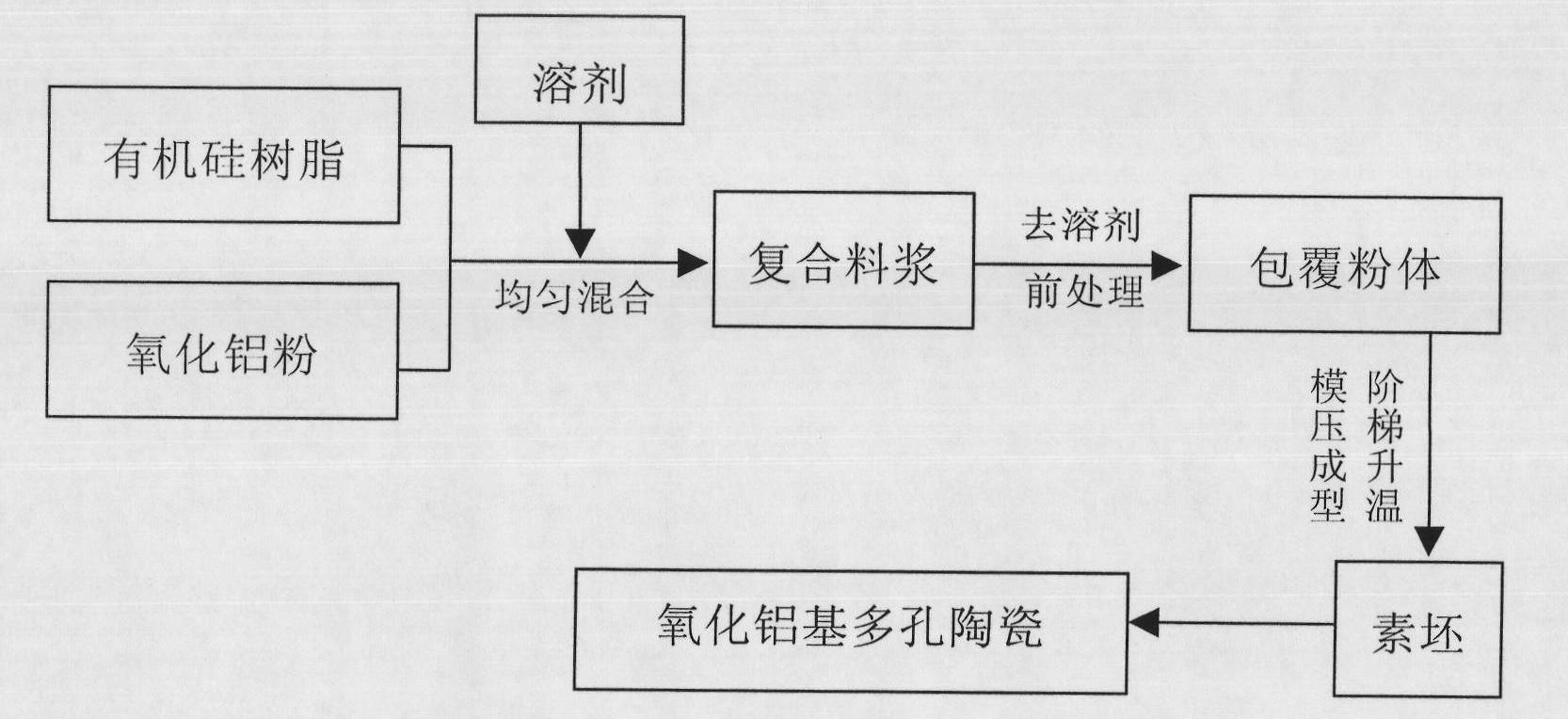

Method used

Image

Examples

Embodiment 1

[0028] (1) uniformly mixing the silicone resin and the alumina powder with a particle size of less than 20 μm in a weight ratio of 4:1;

[0029] (2) Molded by the method of stepped heating molding process system, the axial pressure is 60Mpa, the temperature system is 120°C, 0.5h→150°C, 1h→180°C, 1h→200°C, 0.5h;

[0030] (3) Sintering under normal pressure at 1200° C. under the protection of nitrogen atmosphere, the heating rate is 120° C. / hour, and the temperature is kept for 2 hours. The porosity can be 25%, the bending strength is 57MPa, and the density is 2.03g / cm 3 alumina-based porous ceramic materials.

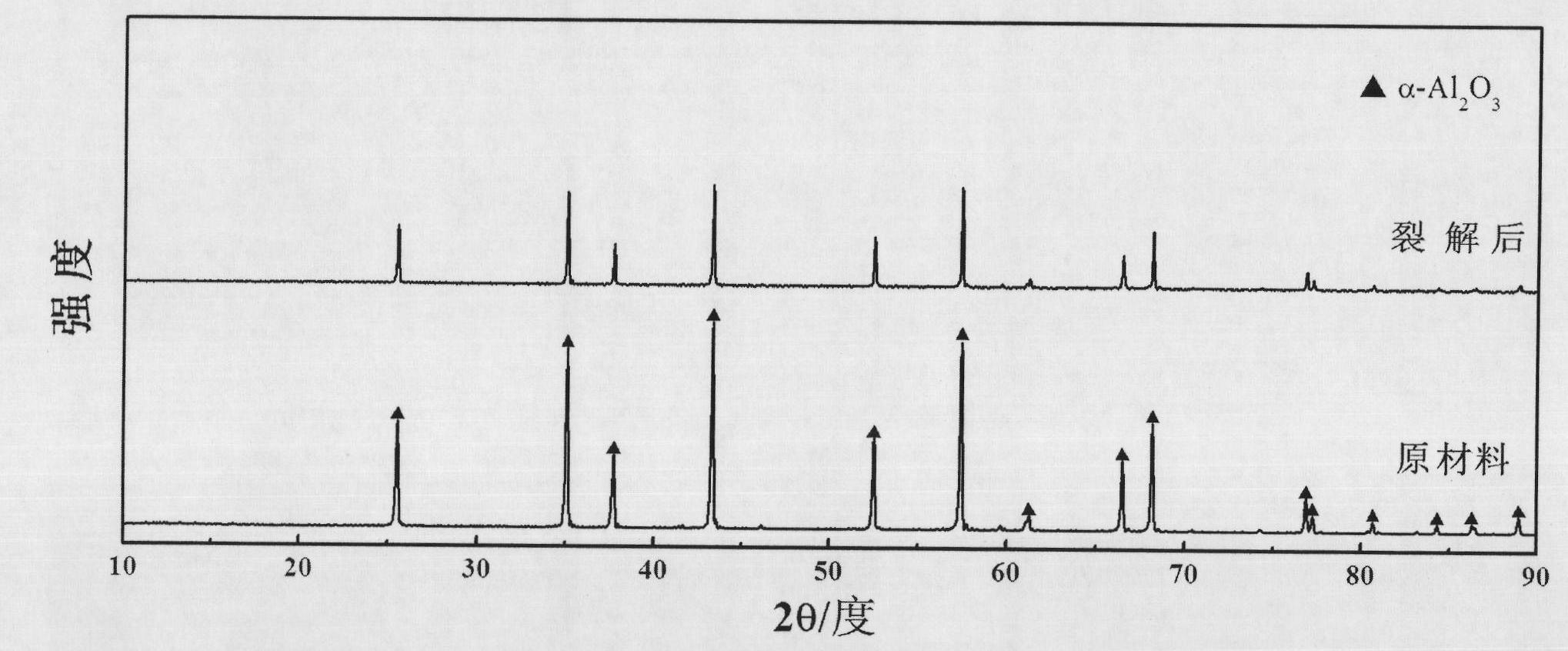

[0031] Analytical tests show that (see figure 2 ): The main phases of the product are α-alumina and γ-alumina, and the main phases of the raw materials are still maintained without phase transition. However, it can be clearly seen that the silicone resin forms a Si-C-O amorphous substance during the cracking process, which weakens the diffraction peak of alumina. Th...

Embodiment 2

[0034] (1) uniformly mixing the silicone resin and the alumina powder with a particle size of less than 20 μm in a weight ratio of 3.3:1;

[0035] (2) Molded by the method of stepped heating molding process system, axial pressure 40Mpa, temperature system 120°C, 1h→150°C, 1h→180°C, 1h→200°C, 1h;

[0036] (3) Cracking is carried out at 1200° C. under the protection of nitrogen atmosphere, the heating rate is 120° C. / hour, and the temperature is kept for 2 hours. The porosity is 31%, the bending strength is 43MPa, and the density is 2.01g / cm 3 alumina-based porous ceramic materials.

Embodiment 3

[0038] (1) uniformly mixing the silicone resin and the alumina powder with a particle size of less than 10 μm in a weight ratio of 3.6:1;

[0039] (2) Molded by the method of stepped heating molding process system, axial pressure 30Mpa, temperature system 120°C, 0.5h→150°C, 1h→180°C, 1h→200°C, 1h;

[0040] (3) Cracking was carried out at 1100° C. under the protection of nitrogen atmosphere, the heating rate was 140° C. / hour, and the temperature was kept for 2 hours. The porosity can be 33%, the bending strength is 36MPa, and the density is 1.98g / cm 3 alumina-based porous ceramic materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com